Challenges in VLSI CAD

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Complexity in VLSI Design

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Welcome everyone! Today, we’ll explore how complexity influences VLSI design. Can anyone tell me how the number of components in a design affects our CAD tools?

I think more components would mean the tools have to be more advanced to handle everything.

Exactly! As designs grow more complex, our algorithms need to scale too. We need more sophisticated strategies to manage data efficiently. Can anyone think of examples where this is needed?

Maybe in designing microprocessors where you have millions of transistors?

Great example! Microprocessors often dictate that CAD systems manage extensive data environments. This complexity adds layers of difficulty in the design process.

To help remember, think of 'C1' for Complexity and '1M' for millions of components!

So it's like a huge puzzle we need to solve!

Exactly! Let’s summarize what we discussed regarding complexity. It requires CAD tools to be scalable and adaptive to higher component counts.

Performance Optimization in VLSI Design

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s move to performance optimization. Why do you think it’s crucial in VLSI design?

It affects how well the circuit works, right? Like keeping it efficient?

Exactly! Designers must balance power consumption, area, and delay. Can anyone explain why this balance is important?

If we only focus on one, the others might suffer. Like making a chip too powerful might use too much power!

Great insight! Remember the acronym 'PAD' — Power, Area, Delay. Keeping these in harmony ensures optimal performance. What happens when we optimize for power but ignore area?

We might end up needing a much larger chip, which isn’t ideal!

Exactly! It's all about trade-offs in design. To recap: optimizing performance involves managing the relationship between power, area, and delay.

Design Verification Challenges

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's talk about design verification. Why is it critical in the VLSI design process?

It helps ensure that what we designed actually works and doesn't have flaws before making it!

Correct! If we don't verify, we might end up failing during fabrication. What methods do we use for verification?

Formal verification and simulations, right?

Absolutely! And these methods help catch defects early. Let’s think of a memorable phrase: 'Verify Before Fabricate' — it'll remind us to double-check designs before moving forward.

That's a good reminder! What if we don’t verify?

Great question! Without verification, we risk producing defective chips, leading to cost overruns and wasted resources. To summarize, verification is essential to the integrity of the design process!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

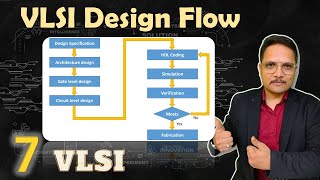

As VLSI designs increase in complexity, VLSI CAD tools and algorithms must evolve accordingly. This section highlights three major challenges: managing complexity, balancing performance parameters like power, area, and delay, and ensuring thorough design verification to avoid defects before fabrication.

Detailed

Challenges in VLSI CAD

The field of Very Large-Scale Integration (VLSI) design presents several significant challenges to computer-aided design (CAD) tools and algorithms. These challenges stem primarily from the increasing complexity of circuit designs, which now can involve millions of components. Here are the main points of concern:

- Complexity: As designs become intricately complex, CAD tools must scale their capabilities to effectively handle an increasing number of components. This necessitates more sophisticated algorithms that can efficiently manage and analyze large design datasets.

- Performance Optimization: Designers often face the challenge of optimizing circuits to balance critical parameters such as power consumption, area allocation on the chip, and signal delay. Achieving an optimal balance among these metrics is crucial for the effective functioning of integrated circuits.

- Design Verification: Ensuring that designs strictly adhere to functional specifications and are free from defects is paramount before fabrication. The verification process employs formal verification techniques and extensive simulations to ensure reliability and correctness. This adds another layer of complexity to the design process, as designers must incorporate these verifications seamlessly into their workflows.

Understanding these challenges is pivotal in appreciating how CAD algorithms and tools must evolve to meet the demands of modern VLSI design.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Complexity in VLSI Design

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Complexity: As VLSI designs become more complex, the algorithms and tools must scale to handle millions of components.

Detailed Explanation

In VLSI design, the complexity of circuits is rapidly increasing due to technological advancements. Today’s integrated circuits can contain millions, or even billions, of components like transistors, capacitors, and resistors. This explosion in scale means that the algorithms and CAD tools used to create these circuits must also evolve. They need to be able to process and manage vast amounts of data, ensuring accurate design and functionality while dealing with the intricacies that come with this complexity.

Examples & Analogies

Think about organizing a large event, like a music festival. Initially, you may have just a few artists and vendors, making it easy to coordinate. However, as the event grows, with hundreds of artists, vendors, and attendees, you need a sophisticated scheduling and coordination tool. Just like that event planner can’t manage everything with paper and pen, VLSI designers can’t use simple tools to handle modern designs; they need smart algorithms to keep up.

Performance Optimization Challenges

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Performance Optimization: Balancing between power consumption, area, and delay is a critical challenge in VLSI design.

Detailed Explanation

In VLSI design, several performance metrics must be optimized simultaneously. Designers often face the 'power-area-delay' tradeoff. Power consumption affects battery life in mobile devices, area impacts the size of the chip and cost of manufacturing, and delay relates to how quickly the circuit can operate. Finding the right balance among these competing demands is a significant challenge, as improving one aspect might worsen another. Designers need to deploy advanced algorithms to simulate and optimize these parameters effectively.

Examples & Analogies

Imagine a chef trying to create the perfect dish. If they want to make a flavorful meal (performance), they might need to add spices (power) and use special cooking techniques (delays). But, if the dish becomes too spicy (excess power), it will be unpleasant to eat, or if it takes too long to prepare (delay), diners might get hungry and leave. Just like the chef has to balance these elements, engineers have to balance power, area, and delay in their designs.

Design Verification Challenges

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Design Verification: Ensuring that designs meet functional specifications and are free from defects before fabrication is a major challenge. Formal verification methods and simulation play key roles in this aspect.

Detailed Explanation

Design verification is a crucial step in the VLSI design process where engineers ensure that their designs function as intended. This involves checking that the design meets all specifications and is free from defects that could cause failures once the chip is fabricated. Verification can be achieved through formal methods that mathematically prove correctness or through simulations that test the design under various conditions. The challenge lies in effectively using these methods to handle the increasing complexity of modern designs while ensuring thoroughness in testing.

Examples & Analogies

Imagine building a bridge. Before the construction starts, engineers need to verify that their designs will hold under various loads and conditions. They might use models to simulate how the bridge will behave in storms or under heavy traffic. Just like these engineers work hard to ensure the bridge is safe before it is built, VLSI designers must verify their circuits to avoid costly mistakes after production.

Key Concepts

-

Complexity: The intricacies of modern VLSI designs necessitating advanced CAD tools.

-

Performance Optimization: Balancing key design parameters for circuit efficiency.

-

Design Verification: Ensuring designs are functionally correct before manufacturing.

Examples & Applications

In designing advanced microprocessors, CAD tools must manage millions of components effectively, leading to complex algorithms.

Balancing power consumption and performance in mobile devices requires critical performance optimization techniques.

Formal verification methods identify potential defects in designs before they pass to fabrication, avoiding costly production errors.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Complexity grows, CADs must adapt, / Power, Area, Delay—fit them as a map.

Stories

Imagine a chef needing to balance flavors—sweet, salty, and sour—to create a perfect dish. Similarly, VLSI design requires a balance among power, area, and delay to achieve optimal performance.

Memory Tools

Remember 'P.A.D.' for Performance Optimization: Power, Area, Delay.

Acronyms

C1 for Complexity and M1 for Millions of components in VLSI designs.

Flash Cards

Glossary

- Complexity

The interconnectedness and intricacy of components in a VLSI design, requiring advanced algorithms to manage.

- Performance Optimization

The process of balancing power consumption, area, and delay to enhance the circuit's overall effectiveness.

- Design Verification

The process of verifying that circuit designs adhere to specifications and are functionally correct.

Reference links

Supplementary resources to enhance your learning experience.