Access to Labour Supply

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Defining Labour Supply

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we'll discuss labour supply and its significance in manufacturing. What do you think labour supply means?

Is it about the number of workers available?

Exactly! Labour supply refers to the availability of workers to fill jobs in various industries. It's crucial for production processes.

But do all industries need the same type of labour?

Good question! Different industries require different skills. For example, manufacturing might need skilled labor for certain tasks while others can operate with less skilled labor.

What about mechanization? Does that change anything?

Yes! Mechanization reduces the reliance on labour but skilled workers are still necessary, especially for overseeing machines or handling complex processes.

To summarize, labour supply is about the fit of workers for job requirements in industries, and it is affected by the skill level and technological advancements.

Importance of Skilled Labour

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, why do you think skilled labour is still important despite more mechanization?

Maybe because some jobs require expertise?

Exactly! Skilled labour allows industries to operate efficiently and innovate. Their expertise is crucial in many manufacturing processes.

Are there industries that still rely heavily on skilled labor?

Yes, industries like aerospace, biotechnology, and high-tech electronics need highly trained workers for quality control and advanced operations.

Remember, while technology changes how we produce, the need for skilled workers is a constant.

Interaction of Factors in Industrial Location

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's look at how labour supply interacts with other factors affecting industrial location. Can anyone name these factors?

Access to raw materials, energy, and markets?

Correct! All these factors work together. For example, industries may choose locations based on proximity to both skilled labour and materials.

So, is it true that some industries can be located anywhere?

Yes! Footloose industries can operate independently of specific resources, but they still need manpower. Their labour needs dictate location choices based on worker availability.

In summary, labour supply is intertwined with materials, energy, and market access, all of which dictate the suitability of an industrial location.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section highlights that labour supply is a crucial factor in the manufacturing process, especially for industries requiring skilled labor. It also notes how mechanization and automation have reduced reliance on labor while maintaining the importance of skilled workers in certain manufacturing processes.

Detailed

In the context of economic activities, access to labour supply is vital for industries, particularly those requiring specialized skills. Historically, a workforce was essential for the manufacturing sector, but advancements in mechanization and automation have alleviated some of this need. However, skilled labor remains critical in several industries. Additionally, factors influencing industrial location, including access to raw materials, transportation, and energy, also interplay with labour supply, creating a holistic picture of industry location dynamics.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Role of Labour Supply in Industrial Location

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Labour supply is an important factor in the location of industries. Some types of industrial manufacturing still require skilled labour.

Detailed Explanation

This chunk illustrates the significance of labor supply in deciding where industries are built. Industries need access to workers who can perform various tasks. For some types of manufacturing, particularly those that are specialized or require craftsmanship, having skilled workers nearby is crucial. Without proper access to labor, industries might struggle to operate efficiently.

Examples & Analogies

Think of a bakery that requires skilled bakers who know how to create pastries and bread. If the bakery is in a location with no skilled bakers, it will have trouble producing quality goods. Similarly, industries need skilled labor nearby to function properly.

Impact of Mechanisation and Automation

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Increasing mechanisation, automation, and flexibility of industrial processes have reduced the dependence of industry upon the labours.

Detailed Explanation

With the advancement of technology, many industries have started to rely less on labor and more on machines. Mechanisation means using machinery to perform tasks that were once done by people. Automation takes this further by using technology that can operate machines with little or no human intervention. As a result, industries are becoming less dependent on a large workforce, which can influence where they choose to set up operations.

Examples & Analogies

Imagine how self-checkout machines in supermarkets mean fewer cashiers are needed. Customers can scan and pay for their items without needing constant human help. The same principle applies in factories where machines can now do the work more efficiently and quickly than humans.

Footloose Industries

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Foot loose industries can be located in a wide variety of places. They are not dependent on any specific raw material, weight losing or otherwise. They largely depend on component parts which can be obtained anywhere.

Detailed Explanation

Footloose industries are those that do not need to be located near their raw materials or markets. They can set up operations in various locations based primarily on availability of labor, favorable economic conditions, and accessibility to transport. This flexibility allows these industries to choose locations that might reduce costs or improve efficiency.

Examples & Analogies

Consider a technology company that designs software. It does not need to be near any specific raw materials (like steel for a car) and can set up its office in any city where there are qualified software developers. This ability to choose the best location for business is what makes them 'footloose.'

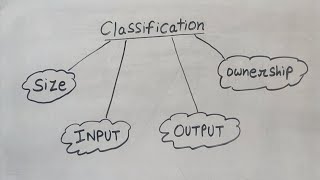

Key Concepts

-

Labour Supply: The availability of workers needed for various levels of industrial production.

-

Skilled Labour: Essential for maintaining quality control in complex manufacturing processes and technology management.

-

Mechanization: Reduces reliance on human labour but doesn't eliminate the need for skilled workers.

-

Footloose Industries: Can operate independently from raw materials, showing the flexibility of labour sourcing.

-

Automation: A trend in manufacturing reflecting the growing reliance on technology over manual labour.

Examples & Applications

The automotive industry relies on skilled workers for assembly line operations, particularly in managing robotic systems.

Footloose industries like tech companies can establish themselves in various locations, utilizing a remote or skilled workforce.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Labour supply, oh my, helps factories fly, with workers nearby!

Stories

Once upon a time in a city, a factory struggled to find skilled workers; then technology came along. Machines helped them, but soon they needed skilled operators to keep everything running smoothly.

Memory Tools

FLAME: Factors influencing Labour Access - Find (access) Labour (supply), Assess skills, Market needs, Energy, and location.

Acronyms

SLEMM

Skills

Labor

Energy

Market

Mechanization.

Flash Cards

Glossary

- Labour Supply

The availability of workers to fill jobs in various industries.

- Skilled Labour

Workers who have specific abilities or expertise in a particular field.

- Mechanization

The use of machines to perform tasks that were previously done by hand.

- Footloose Industries

Industries that can be located in a wide variety of places, not tied to specific raw materials.

- Automation

The use of technology to perform tasks with minimal human intervention.

Reference links

Supplementary resources to enhance your learning experience.