Cold Weather Concreting

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Cold Weather Concreting

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're diving into cold weather concreting! Why do you think it's important to understand how cold weather affects concrete?

Because if it's too cold, the concrete won't set properly!

Exactly! That's why we use special techniques and admixtures to help concrete set even when the temperatures drop. Can anyone name an essential method for achieving this?

Using accelerators?

Correct! Accelerators help speed up the setting time. Think of them as a boost for concrete. Now, who can explain why we avoid using retarders in cold weather?

Because they can delay the setting too much, right?

Yes! Retarders can prevent freezing before the concrete sets, which is critical. Summarizing our discussion: cold weather poses challenges, but using accelerators effectively helps manage these issues.

Effects of Temperature on Concrete

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's talk about temperature! What happens to concrete when it's poured in cold weather?

It might freeze before it can set properly.

Exactly. If concrete freezes before it sets, it can crack and lose strength. What are some strategies to prevent this?

Heaters or insulated blankets might be used!

Good ideas! Also, using accelerators in the mix can help. Can anyone remember one type of accelerator we discussed?

Triethanolamine!

That's right! Keeping the concrete temperature above freezing during initial set is vital for success. Great engagement, everyone!

Practical Applications

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we understand the theory, let’s look at practical applications of cold weather concreting. Can someone share a scenario where these techniques would be beneficial?

Like when building bridges in the winter?

Exactly, bridges often require pouring concrete in challenging temperatures. What admixtures might they use there?

They could use calcium chloride or triethanolamine to help with the strength.

Perfect! These admixtures can help ensure that they achieve the required strength on time. In summary, understanding the tools and techniques for cold weather concreting can significantly impact project timelines and outcomes.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section emphasizes the methods and precautions necessary for successful cold weather concreting, highlighting the role of accelerators and the avoidance of retarders to ensure proper setting and strength development.

Detailed

Cold Weather Concreting

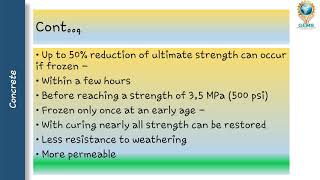

Cold weather can significantly affect the setting and hardening of concrete, necessitating special considerations when planning concrete works. During low-temperature conditions, achieving the desired early strength becomes crucial, especially in construction projects that cannot afford delays. In this context, several techniques and admixtures are utilized to counteract the challenges posed by cold weather.

Key Techniques and Admixtures

- Use of Accelerators: Admixtures like triethanolamine and various calcium-based compounds are popular choices to promote early strength development in cold conditions.

- Avoidance of Retarders: While retarders are beneficial in other scenarios, their use in cold weather should be avoided to prevent freezing issues before concrete sets.

Importance of Temperature Control

Maintaining a temperature above freezing before the concrete reaches initial set is vital. Understanding how temperature influences the curing process allows project managers to mitigate risks associated with adverse weather conditions, ensuring the longevity and stability of the concrete structure.

Conclusion

By utilizing appropriate admixtures and methods, cold weather concreting can achieve desired performance levels, thereby sustaining project timelines and ensuring structural integrity.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Use of Accelerators

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Accelerators like triethanolamine used to achieve early strength despite low temperatures.

Detailed Explanation

In cold weather concreting, accelerators are added to the concrete mix to speed up the setting time. One example of an accelerator is triethanolamine, which helps the concrete achieve strength quickly, even when temperatures are low. Cold temperatures slow down the chemical reactions in the concrete, which can delay the setting process. By using accelerators, we can counteract this delay and ensure that the concrete reaches the necessary strength in a timely manner.

Examples & Analogies

Imagine you are trying to boil water on a cold day. It takes longer to boil than it would on a hot day. Now, if you had a device that could heat the water faster, you would achieve boiling quicker. Similarly, accelerators in concrete help to increase the 'heat' of the concrete curing process, allowing it to set more rapidly despite the chilling temperatures.

Avoiding Retarders

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Retarders avoided to prevent freezing before set.

Detailed Explanation

In cold weather, it’s important not to use retarders, which are typically added to delay the setting time of concrete. If retarders are used in cold conditions, there is a risk that the concrete may not set before it begins to freeze. Freezing can adversely affect the concrete's strength and durability. Therefore, in cold weather mixing conditions, the goal is to use materials that will help the concrete set faster to avoid any freezing issues.

Examples & Analogies

Think about when you leave ice cream out on a cold day. If you wait too long, it starts to freeze solid again, making it unusable. Similarly, if concrete is not set quickly enough and begins to freeze, it can become damaged and unusable. Avoiding retarders in this scenario ensures the concrete solidifies correctly before cold temperatures can harm it.

Key Concepts

-

Cold Weather Concreting: Techniques to ensure concrete sets properly despite low temperatures.

-

Accelerators: Chemicals that speed up the curing process, particularly useful in cold conditions.

-

Avoiding Retarders: Essential for preventing freezing before the concrete can properly set.

Examples & Applications

Using triethanolamine as an accelerator in cold weather to enhance early strength.

Employing insulated blankets to maintain positive temperatures on poured concrete.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Cold concrete likes to freeze in the night; use accelerators to set it right!

Stories

Imagine a construction worker facing a winter storm; he grabs accelerators and insulates the forms, ensuring the concrete stays warm amidst the frigid winds while they pour the slab.

Memory Tools

A.R.E. - Accelerate, Retarders avoided, Ensure warmth for proper setting.

Acronyms

COLD - Concrete Optimization in Low Degrees - Keep concrete setting properly in cool weather.

Flash Cards

Glossary

- Accelerators

Admixtures that increase the rate of hydration in concrete, leading to faster setting and early strength development.

- Retarders

Admixtures that decrease the rate of hydration, delaying the setting time of concrete.

- Freezing Point

The temperature at which moisture in concrete turns into ice, potentially disrupting the curing process.

Reference links

Supplementary resources to enhance your learning experience.