Hot Weather Concreting

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Hot Weather Effects

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we’re going to talk about hot weather concreting. Can anyone tell me why hot weather is a concern for concrete?

I think it has to do with the concrete setting too fast.

Correct! Rapid setting can lead to issues like cracks. In hot weather, evaporation can also cause water loss, which compromises strength. To remember this, think of the acronym HEAT: Hydration, Evaporation, Acceleration, and Temperature.

What happens if the water evaporates too quickly?

Good question! Excessive water loss can cause scaling and contribute to surface cracking. It’s vital to maintain hydration during the curing process.

Using Retarders Effectively

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's discuss reducers now. Retarders play an important role in hot weather. Who can tell me their purpose?

They delay the setting time of concrete, right?

Exactly! By slowing down the setting process, they allow workers more time for placement and finishing. Remember this: 'Set Slow, Work Flow.'

Can they be used all the time?

Great insight! While they are beneficial in hot weather, over-application can cause excessive delays. Always follow the manufacturer’s recommendations.

Curing and Finishing Techniques

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s talk about curing techniques. What methods can help protect concrete from hot conditions?

Shading and using wet burlap?

Right! Applying wet burlap helps maintain moisture levels. Additionally, misting can be effective. Think of the phrase, 'Misty Moist Concrete is Mighty Durable!'

What about the wind? Does it affect curing?

Absolutely! Wind can increase evaporation rates. Implementing windbreaks can significantly help in protecting freshly poured concrete.

Practical Examples

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let’s look at examples of hot weather concreting. Can anyone share instances where these practices would be essential?

Pouring a foundation during summer?

Exactly! Any outdoor pouring in high temperatures needs careful planning. Think of the acronym SAFE: Shade, Add Retarders, Finish Early, Evaporative Control.

What are some signs that indicate curing isn't effective?

Signs include surface cracking, scaling, and weaker concrete overall. Observing these symptoms can prevent costly issues down the line.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

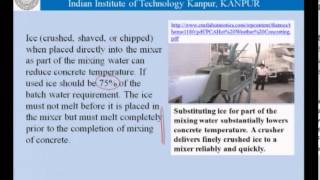

In hot weather, concrete can set too quickly and suffer from evaporation loss, which can compromise its strength and integrity. This section discusses the use of retarders to extend setting time, air-entrainers to minimize evaporation, and methods to ensure proper finishing and curing.

Detailed

In hot weather conditions, the risk of concrete setting too quickly can lead to surface cracking and compromised strength. Therefore, it is essential to implement specific strategies to mitigate these risks during the mixing, pouring, and curing processes. This includes utilizing retarders that delay the setting time of concrete, allowing adequate time for placing and finishing. Air-entraining admixtures can also be incorporated to reduce evaporation and improve the resulting concrete’s performance. Furthermore, protective measures such as proper shading, wet curing, and windbreaks are recommended to ensure optimal hydration and curing of poured concrete. These practices are paramount in maintaining the structural integrity and durability of concrete installations in hot climates.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Purpose of Retarders in Hot Weather

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Retarders extend setting time and help place and compact concrete before initial set.

Detailed Explanation

In hot weather conditions, temperatures can rise significantly, which can cause concrete to set too quickly. To manage this, retarders are added to the concrete mix. These chemicals work by slowing down the hydration process of the cement, which essentially delays the setting time. This gives workers more time to properly place and finish the concrete before it hardens, preventing issues like uneven surfaces or cold joints.

Examples & Analogies

Think of it like a frozen dessert on a hot day. If you scoop ice cream out of the tub too quickly, it melts and becomes messy. But if you wait a bit and use a tool that controls the melting, you can serve it just how you want. Similarly, retarders help manage the 'melting' or setting process of concrete.

Role of Air-Entrainers in Hot Weather

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Air-entrainers reduce evaporation and improve finish.

Detailed Explanation

In addition to retarders, air-entraining agents are also used during hot weather concreting. These admixtures introduce tiny air bubbles into the concrete mix. These air pockets help to trap moisture, reducing the rate of evaporation from the surface when it’s hot. This is crucial because high evaporation rates can lead to surface cracking, which compromises the integrity of the concrete. Furthermore, the presence of these air bubbles improves the finish of the concrete by allowing it to be worked more easily.

Examples & Analogies

Imagine blowing bubbles into a drink. The bubbles help keep the drink from spilling over too quickly. Similarly, the tiny air pockets created by air-entrainers keep the moisture in the concrete, preventing it from drying out and cracking.

Key Concepts

-

Hydration: The process of water reacting with cement to form a solid structure.

-

Evaporation Control: Measures taken to reduce the loss of water from fresh concrete.

-

Use of Retarders: Admixtures that slow down setting time to allow workability.

-

Curing Techniques: Methods to maintain moisture in concrete during the curing period.

Examples & Applications

Using retarders in concrete mixes for roadwork in summer to prevent cracks.

Employing windbreaks during a high-temperature construction project to mitigate evaporation.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In the heat, don’t forget to treat, with shade and water, the mix must greet.

Stories

Once, a builder named Sam poured concrete on a hot sunny day without any care. The concrete set too fast, and his project cracked. Then, he learned to use retarders and shade the surface, and all went well!

Memory Tools

To remember hot weather concreting, think 'SHAPE': Shade, Hydrate, Add Retarders, Place, and Evaporate Control.

Acronyms

HEAT

Hydration

Evaporation

Acceleration

Temperature.

Flash Cards

Glossary

- Retarders

Admixtures that delay the setting time of concrete to allow for better placement and finishing.

- Evaporation

The process by which moisture is lost from the surface of the concrete, potentially compromising strength.

- Curing

The process of maintaining adequate moisture, temperature, and time to allow the concrete to achieve its desired strength.

- Hydration

The chemical process involving the reaction between water and cement which forms the hardened structure of concrete.

- Windbreaks

Structures or methods employed to reduce wind speed over freshly placed concrete, protecting it from evaporation.

Reference links

Supplementary resources to enhance your learning experience.