Field Applications and Case Studies

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Bridge Construction in Coastal Zones

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we’re going to discuss the role of chemical admixtures in bridge construction, particularly in coastal zones. What do you think is the primary concern when building bridges in such environments?

Maybe the saltwater could damage the concrete?

Exactly! That’s why we use corrosion-inhibiting admixtures, such as calcium nitrite, which protect the reinforcement steel from chloride attack. Can anyone tell me why air-entraining agents are also important here?

They help with freeze-thaw resistance, right?

Correct! They create tiny air bubbles in the concrete that make it more durable against freezing temperatures. This combination enhances the overall longevity of bridges in coastal areas.

How about the cost? Does it increase a lot by adding these admixtures?

Good question! While there might be an initial increase in cost due to these admixtures, the long-term savings in maintenance and repairs often outweigh the expenses. It’s an investment in durability.

To summarize, using corrosion inhibitors and air-entraining admixtures in coastal bridge projects significantly enhances durability and longevity by preventing damage from chloride ions and improving freeze-thaw resistance.

Metro and Tunnel Projects

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Moving on to metro and tunnel projects. What type of admixture do you think is crucial for making concrete more pumpable for such applications?

Superplasticizers would be necessary, right?

Exactly! Superplasticizers help achieve high strength while keeping the concrete workable for pumping. What about waterproofing? Why is it particularly important in tunnels?

Because water leakage could really disrupt transportation systems underground.

Right! Waterproofing admixtures prevent leakage and ensure the integrity of the tunnel walls. Can anyone summarize how both types of admixtures work together in these projects?

Superplasticizers make the concrete easy to pump, while waterproofing admixtures stop water from getting in and damaging the structure.

Great summary! In essence, the combination of superplasticizers and waterproofing admixtures is vital for maintaining structural stability and functionality in metro and tunnel projects.

Cold Weather Concreting

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let’s discuss cold weather concreting. Why do you think concrete can be challenging to work with in cold conditions?

Because it might freeze before it sets?

Exactly! To tackle this, we often use accelerators like triethanolamine, which promote early strength development. But what should we avoid using in these situations?

Retarders, because they could delay the setting even more, right?

You've got it! Using retarders in cold weather could lead to problems with freezing. In summary, when it’s cold, we can use accelerators to ensure timely setting and avoid retarders to prevent freezing issues.

Hot Weather Concreting

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let’s discuss hot weather concreting. What issues arise when working with concrete in such conditions?

The concrete can set too quickly and crack?

That’s correct! To manage fast setting, we use retarders to extend the working time. What role do air-entraining admixtures play here?

They help reduce evaporation, right?

Exactly! Preventing evaporation is crucial to keeping the concrete workable. So, can someone summarize our tools for hot weather concreting?

We use retarders to slow down the setting process and air-entrainers to reduce evaporation.

Great summary! In hot conditions, these two types of admixtures work together to improve the performance and workability of concrete.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section outlines diverse field applications of chemical admixtures in concrete construction, detailing their significance in bridge construction, metro projects, and conditions like cold and hot weather. Each application illustrates how specific admixtures enhance durability, strength, and workability.

Detailed

Field Applications and Case Studies

Overview

This section covers the various real-world applications of chemical admixtures in concrete construction, demonstrating how these materials significantly improve the performance of concrete in different environmental and operational settings.

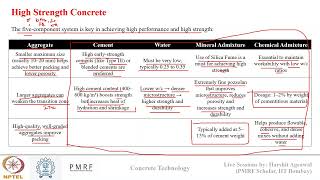

Key Applications

- Bridge Construction in Coastal Zones:

- Admixtures Used: Corrosion-inhibiting admixtures like calcium nitrite.

- Benefits: Protects reinforcement from chloride-induced corrosion, enhancing the longevity of structures in harsh environments.

- Air-entraining agents are also utilized to improve the durability of concrete exposed to saline conditions.

- Metro and Tunnel Projects:

- Admixtures Used: Superplasticizers help reduce water content without impacting workability, creating high-strength and pumpable concrete suited for these infrastructures.

- Waterproofing admixtures are critical in segment linings, ensuring leakage prevention in underground environments.

- Cold Weather Concreting:

- Admixtures Used: Accelerating agents like triethanolamine facilitate early strength gain, crucial for workability in low temperatures.

- Precautions: Retarders are avoided to prevent the risk of freezing before setting, ensuring timely concrete placement.

- Hot Weather Concreting:

- Admixtures Used: Retarding admixtures help extend setting times, allowing for proper placing and finishing.

- Air-entrainers assist in minimizing evaporation and improving the surface finish of the concrete.

Conclusion

These field applications highlight the critical role of chemical admixtures in enhancing concrete performance according to specific operational requirements and environmental challenges, making them indispensable in modern construction practices.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Bridge Construction in Coastal Zones

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Use of corrosion-inhibiting admixtures (e.g., calcium nitrite) to protect rebar from chloride attack.

Air-entraining agents enhance durability under salt exposure.

Detailed Explanation

In coastal regions, concrete structures like bridges are exposed to salty environments, which can cause corrosion of the reinforcing steel bars (rebar) embedded in the concrete. To prevent this, engineers use corrosion-inhibiting admixtures such as calcium nitrite. These admixtures create a protective barrier around the rebar, reducing the likelihood of chloride ions penetrating and causing rust. Additionally, air-entraining agents are added to the concrete mix to produce tiny air pockets within the concrete. This enhances the durability of the concrete when exposed to saline conditions by improving the freeze-thaw resistance and reducing the risk of cracking.

Examples & Analogies

Think of corrosion-inhibiting admixtures as sunscreen for the bridge's steel reinforcements. Just as sunscreen protects your skin from harmful UV rays, these admixtures shield the rebar from saltwater. Imagine building a sandcastle at the beach; if you add tiny air pockets to the sand mixture, it becomes more resistant to waves crashing on it, just like air-entrained concrete withstands harsh weather conditions.

Metro and Tunnel Projects

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Superplasticizers reduce water content for high-strength, pumpable concrete.

Waterproofing admixtures used in lining segments to prevent leakage.

Detailed Explanation

In metro and tunnel projects, high-strength concrete is essential for structural integrity and sustainability due to the high loads and environmental conditions the concrete will face. Superplasticizers are employed to significantly reduce the amount of water needed in the concrete mix while maintaining a workable consistency. This allows for the production of high-strength concrete that can be easily pumped into place. Furthermore, waterproofing admixtures are used in the lining segments of tunnels to prevent any water leakage, ensuring that the infrastructure remains dry and safe from water damage.

Examples & Analogies

Consider a thick smoothie: if you want it to be creamy without adding too much milk, you can use ice and bananas to thicken it up. Similarly, superplasticizers allow concrete to maintain a good flow without requiring extra water, making it strong and easy to handle. Think of waterproofing admixtures as raincoats for the concrete lining in tunnels, preventing leaks from rain or ground water, just like a raincoat keeps you dry in a downpour.

Cold Weather Concreting

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Accelerators like triethanolamine used to achieve early strength despite low temperatures.

Retarders avoided to prevent freezing before set.

Detailed Explanation

When pouring concrete in cold weather, low temperatures can significantly slow down the curing process. To counteract this, accelerators, such as triethanolamine, are often added to the concrete mix. These chemicals help to speed up the hydration process, allowing the concrete to gain strength more quickly before it freezes. However, it's important to avoid using retarding admixtures in these conditions, as they could delay the setting time, putting the concrete at risk of freezing before it has fully cured.

Examples & Analogies

Imagine trying to bake bread in a cold kitchen; it takes much longer for the dough to rise. By using a warming oven, you create a better environment for the dough. Similarly, accelerators warm up the concrete's curing process so it can set properly in cold conditions. If you were to add a cooling agent while trying to bake, it would mess up the whole process; that's why retarders can be problematic in chilly climates.

Hot Weather Concreting

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Retarders extend setting time and help place and compact concrete before initial set.

Air-entrainers reduce evaporation and improve finish.

Detailed Explanation

In hot weather, concrete can set too quickly, which may lead to cracks and poor finish quality. To address this issue, retarders are introduced into the mix. These admixtures help to prolong the setting time, allowing workers to pour, place, and compact the concrete effectively before it starts to harden. Additionally, air-entraining agents are added to mitigate the risk of moisture evaporation from the surface, which can adversely affect the final appearance and durability of the concrete.

Examples & Analogies

Think about icing a cake in a hot kitchen; if the frosting starts to melt, you can't get a nice smooth finish. Retarders act like air conditioning for the cake, allowing you extra time to get it just right. On the other hand, air-entrainers are like a cooling rack, ensuring the frosting doesn’t melt away completely, giving the cake a better appearance and taste, similar to how they help maintain the quality of the concrete.

Key Concepts

-

Corrosion Resistance: The importance of using corrosion-inhibiting admixtures in coastal construction.

-

Pumpability: Why superplasticizers are essential for concrete used in tunnels and metro projects.

-

Early Strength Gain: The use of accelerators in cold weather to ensure setting and strength.

-

Setting Time Extensions: The role of retarders in hot weather to manage fast setting.

Examples & Applications

In bridge construction, calcium nitrite is used to protect rebar from chloride corrosion in coastal areas.

Metro construction employs superplasticizers to ensure high-strength pumpable concrete while waterproofing admixtures prevent leakage.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In cold or hot, we must cope, with admixtures giving us hope. Protect steel, make it strong, in the concrete, where it belongs.

Stories

Once upon a time, in a coastal town, a bridge stood tall. To keep it strong against the salty air, the builders added a magical potion—corrosion inhibitors—keeping the steel safe while the waves crashed around. This way, the bridge lasts through storms and years without worry!

Memory Tools

For concrete in cold, remember CARS: C for Accelerators, A for Avoiding retarders, R for Rapid setting, and S for Strength gain!

Acronyms

WAVE

Waterproofing

Air-entraining

Velocity of flow (from superplasticizers)

and Enhancing workability.

Flash Cards

Glossary

- Corrosioninhibiting admixtures

Chemical additives that protect steel reinforcement from corrosion, particularly in aggressive environments.

- Superplasticizers

Admixtures that significantly increase the flow of concrete while reducing the water-cement ratio.

- Waterproofing admixtures

Admixtures that minimize water permeability in concrete, typically used in structures exposed to water.

- Accelerators

Admixtures that speed up the setting time and early strength development of concrete.

- Retarders

Admixtures that slow down the setting time of concrete, allowing for extended workability.

Reference links

Supplementary resources to enhance your learning experience.