Conclusion

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Importance of Testability in Digital Circuits

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will discuss the vital role of testability in digital circuits. Can anyone tell me why testability is important?

I think it's to make sure the circuits work correctly after being manufactured.

And to find any faults that might occur.

Exactly! Testability allows us to verify the functionality of complex circuits efficiently. We accomplish this with techniques like scan chains and serial testing.

How do these techniques help in fault detection?

Scan chains enhance observability and controllability, allowing us to access and test internal states effectively. This means we can quickly identify and rectify faults before production.

To remember this, think of 'O.C.' for Observability and Control.

In summary, the key takeaway is that testability is crucial for ensuring reliability in digital designs.

Benefits of Scan Chains

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's delve into the benefits of implementing scan chains. Why do we think scan chains are beneficial?

They make it easier to access the internal circuitry for testing.

And they can help find both combinational and sequential faults.

Exactly! Scan chains provide high fault coverage and simplify the testing process, notably in complex ICs.

Do they also reduce testing time?

Yes, that's a significant advantage! They reduce testing costs and improve product reliability by identifying defects early.

To help remember this, think of 'F.A.S.T.' for Faster, Affordable, Simpler Testing.

In conclusion, scan chains are indispensable tools in DFT.

Challenges of Implementing Scan Chains

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

While scan chains offer many benefits, what challenges can you think of related to their implementation?

They probably add design complexity and cost, right?

And what about their effectiveness on analog circuits?

Great points! Scan chains increase design overhead and are not suitable for analog or mixed-signal testing. This can be a significant limitation.

So they might not detect every type of fault?

Correct! As systems become more complex, some faults may go undetected. Thus, diversifying testing strategies is crucial.

In summary, while beneficial, we must also consider the design complexity and fault coverage limitations when using scan chains.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

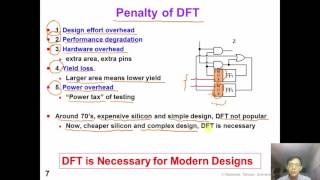

In the conclusion, scan chains and serial testing are presented as fundamental components of Design for Testability (DFT), playing a critical role in improving fault detection and circuit reliability. Despite their benefits, the section also addresses the challenges associated with their implementation, particularly regarding design complexity and suitability for various types of systems.

Detailed

In this section, we summarize the pivotal role of scan chains and serial testing in ensuring the testability of digital circuits, crucial for modern electronics. Scan chains offer engineers the ability to control and monitor internal circuit states efficiently, promoting improved observability and controllability. This chapter has highlighted how these tools contribute to fault detection and verification of system functionality while simultaneously addressing challenges like increased design overhead and limitations in testing specific circuit types. As digital systems evolve, the integration of such strategies within Design for Testability (DFT) practices remains essential for maintaining the reliability and performance of contemporary electronic systems.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Importance of Scan Chains and Serial Testing

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Scan chains and serial testing are fundamental tools in the design of testable digital circuits, offering efficient methods for detecting faults, verifying functionality, and improving overall product quality.

Detailed Explanation

This chunk emphasizes the vital role that scan chains and serial testing play in the testing of digital circuits. They provide a way for engineers to efficiently find errors (faults) in the circuitry, confirm that the circuit works as intended (functionality), and enhance the quality of the final product. This means they help ensure the digital devices we rely on function correctly and reliably.

Examples & Analogies

Think of scan chains and serial testing like a quality control check in a factory. Just like a factory might test products at various stages of production to ensure they meet quality standards, scan chains and serial testing allow engineers to check the internal workings of digital circuits at different points to catch and fix problems before the product is completed.

Benefits of Embedding Scan Chains

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

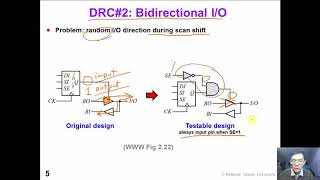

By embedding scan chains into the design, engineers can access and test the internal states of a circuit, providing greater observability and controllability during the testing process.

Detailed Explanation

Embedding scan chains into circuit designs means that engineers gain direct access to the internal workings of the circuit. This allows them to observe how the circuit behaves and control its operation during testing. Greater observability means engineers can see what is happening inside the circuit in real time, while controllability allows them to manipulate inputs to check different operational conditions, making the testing process much more thorough and efficient.

Examples & Analogies

Consider a mechanic inspecting a car's engine. If the engine was covered and inaccessible, diagnosing issues would be extremely challenging. However, if the mechanic could easily look inside and see all the parts (similar to how scan chains allow engineers to access internal states), it would be much easier to identify and fix problems - this is what embedding scan chains achieves in digital design.

Challenges in Implementation

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

While they offer significant benefits in terms of fault coverage, testing speed, and cost reduction, challenges such as increased design complexity and limitations in testing analog circuits must be considered when implementing scan-based testing strategies.

Detailed Explanation

Despite the various advantages that scan chains and serial testing bring, there are some challenges. For instance, adding scan chains into a design can make the overall circuit more complex, which can lead to more costly manufacturing and design processes. Additionally, scan chains primarily focus on digital circuits, meaning engineers need other strategies when dealing with analog circuits, which can have different behaviors that scan chains are not equipped to handle.

Examples & Analogies

Imagine trying to add a complex security system to an already sophisticated building. While the new system could enhance safety (similar to how scan chains improve testing), it could also complicate the overall structure and design of the building, increasing both costs and maintenance challenges – this is akin to the challenges faced when implementing scan chains.

The Future Role of Scan Chains

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

As digital circuits continue to grow in size and complexity, scan chains and serial testing will remain essential components of Design for Testability (DFT), ensuring the reliability and performance of modern electronic systems.

Detailed Explanation

This chunk highlights that as technology advances, digital circuits are becoming more intricate. Consequently, the need for effective testing methods is more critical than ever. Scan chains and serial testing are anticipated to be crucial tools in ensuring that these advanced circuits work reliably and meet performance standards, fulfilling the essential role they play in Design for Testability.

Examples & Analogies

Think of it this way: as the demands for smartphones increase (more apps, better graphics, etc.), the complexity of their internal circuits grows. Just as car manufacturers invest in new testing technologies to ensure their vehicles perform well amidst complexity growth, the electronics industry will continue to use and refine scan chains and serial testing to keep up with increasing digital circuit demands.

Key Concepts

-

Scan Chains: Structures that allow access to internal states for testing.

-

Serial Testing: Method of applying test vectors sequentially for fault detection.

-

Fault Detection: Process of identifying faults in circuit components.

-

Observability and Controllability: Key advantages of scan chains.

-

Design Overhead: The extra complexity introduced by integrating scan chains.

Examples & Applications

Using a scan chain in a microcontroller to diagnose operational faults.

Implementing serial testing in a digital signal processor to verify signal integrity.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Scan chains stack like a train, testing circuits is their main gain.

Stories

Imagine a train (scan chain) that moves through a network (circuit), collecting data along the way (testing internal states) and ensuring the route is clear of obstacles (faults).

Memory Tools

Remember 'O.C.' for Observability and Control when thinking of scan chains.

Acronyms

Use 'F.A.S.T.' to recall the benefits

Faster

Affordable

Simpler Testing of circuits.

Flash Cards

Glossary

- Scan Chains

A series of flip-flops connected together, allowing for the shift of data into and out of the internal states during testing.

- Serial Testing

A testing approach that applies test vectors in a serial manner to check internal behaviors of the system.

- Observability

The ability to observe the internal states of a circuit through the scan-out process.

- Controllability

The ability to control the inputs to the flip-flops, allowing for simulation of various conditions.

- Fault Coverage

The extent to which a testing strategy can detect different types of faults within a circuit.

Reference links

Supplementary resources to enhance your learning experience.