Embedded Systems in Industrial Automation

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Embedded Systems in Industrial Automation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we'll explore how embedded systems contribute to industrial automation. Can anyone summarize what industrial automation refers to?

It’s about using control systems like computers or robots to operate processes automatically.

Exactly! Now, can someone explain what embedded systems do within this context?

They help monitor and control machinery, making operations more efficient.

That's right! Think of embedded systems as the brains behind automated equipment. Can anyone give me an example of where we might find embedded systems in industrial automation?

PLCs, or Programmable Logic Controllers, are one example!

Great example! PLCs control industrial machinery and automate tasks. Remember: PLC = Programmable Logic Control. Let's keep this in mind. To summarize today's main concepts: embedded systems control and optimize machinery and processes in industrial settings.

Applications of Embedded Systems

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's go deeper into the specific applications of embedded systems in industrial automation. What applications can you think of?

Robotics in factories, like assembly lines!

Exactly! Embedded systems are crucial in robotics. They also enable precision in tasks like inspection and welding. Can someone tell me about SCADA systems?

SCADA systems monitor and control industrial processes from a distance, right?

Correct! SCADA is critical for operational safety and efficiency. Lastly, let’s not forget about sensor networks—how do these relate to embedded systems?

They collect data in real-time to help optimize processes!

Very good! So, embedded systems enhance productivity and optimize performance in industrial settings. Remember: more automation = less error, and this can lead to cost reduction in operations.

Significance of Embedded Systems

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s summarize the significance of embedded systems in industrial automation. Why are they important?

They improve efficiency and productivity by automating tasks!

Absolutely! And what about real-time control?

They help with continuous monitoring and quick responses!

Exactly! It's all about keeping processes running smoothly. Plus, what are the cost benefits of automating with embedded systems?

It reduces labor costs and minimizes errors, leading to lower production costs!

Perfect! To tie it all together: embedded systems lead to efficiency, real-time control, and significant cost reductions. Remember: automation saves labor, boosts efficiency, and enhances reliability!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section explores the critical role of embedded systems in industrial automation, detailing their applications in programmable logic controllers, robotics, SCADA systems, and sensor networks. It highlights the significance of these systems in boosting productivity, real-time monitoring, and cost reduction in industrial processes.

Detailed

Embedded Systems in Industrial Automation

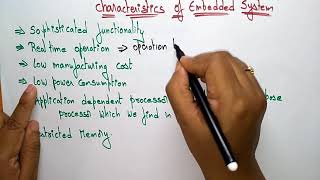

Embedded systems are integral to industrial automation, significantly impacting how machinery and processes are controlled. This section outlines key applications of embedded systems in this sector:

Key Applications of Embedded Systems in Industrial Automation:

- Programmable Logic Controllers (PLCs): These embedded systems are vital for controlling industrial machinery, automating tasks, and monitoring various sensors to optimize operations.

- Robotics: Embedded systems empower robots to perform various functions, including material handling, assembly, inspection, and welding, guaranteeing high precision and efficiency.

- SCADA Systems: Supervision Control and Data Acquisition (SCADA) systems utilize embedded systems to remotely monitor and control industrial processes, such as power grids and water treatment plants, enabling operational continuity and safety.

- Sensor Networks: Embedded systems in sensor networks collect real-time data on parameters like temperature and pressure, which is essential for optimizing industrial operations.

Significance of Embedded Systems in Industrial Automation:

- Efficiency and Productivity: By automating repetitive and complex tasks, embedded systems improve overall production efficiency and output.

- Real-time Control: They allow for continuous monitoring and quick responses to any operational disruption, ensuring efficient management of industrial processes.

- Cost Reduction: Automation reduces labor costs, minimizes errors, and lowers overall production expenses, making them vital in competitive markets.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Programmable Logic Controllers (PLCs)

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

PLCs are embedded systems used for controlling industrial machinery, monitoring sensors, and automating tasks like assembly and packaging.

Detailed Explanation

Programmable Logic Controllers (PLCs) are specialized embedded systems designed to perform automation tasks in industrial environments. They control machinery by interpreting signals from various sensors, allowing for precisely timed operations such as assembly and packaging. For example, when a sensor detects that a product has reached the end of a conveyor belt, the PLC can trigger a robotic arm to pick that product off the belt. This seamless interaction helps streamline manufacturing processes and reduce human error.

Examples & Analogies

Think of a PLC as the conductor of an orchestra. Just like a conductor ensures that all musicians play in harmony and at the right time, a PLC coordinates the actions of machines in a factory to make sure everything operates smoothly.

Robotics

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Embedded systems enable robots to perform tasks like material handling, assembly, inspection, and welding with high precision.

Detailed Explanation

In industrial automation, robots equipped with embedded systems are capable of executing various complex tasks such as handling materials, assembling products, inspecting for quality, and performing precise welding. The embedded systems in these robots allow them to process data from their environment, make decisions in real-time, and act accordingly. For instance, if a robot detects an anomaly in a product during inspection, it can halt the assembly line to prevent defective items from being shipped.

Examples & Analogies

Imagine a chef in a kitchen. The chef uses various tools (like knives, pots, and timers) to prepare a meal efficiently. Similarly, embedded systems in industrial robots act as the chef's tools, helping them perform specific tasks with accuracy and control, ensuring that the 'meal' (or product) is perfect every time.

SCADA Systems (Supervisory Control and Data Acquisition)

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Embedded systems are part of SCADA systems, used to monitor and control industrial processes remotely (e.g., power grids, oil refineries, water treatment plants).

Detailed Explanation

SCADA systems leverage embedded systems to enable the remote monitoring and control of industrial processes. These systems collect data from various sensors and provide operators with real-time updates on the status of operations. For instance, in a water treatment plant, embedded systems in SCADA can monitor water quality and automatically adjust chemical inputs to ensure safety standards are met. This capability greatly enhances operational efficiency and responsiveness, as operators can quickly address issues without being physically present at the plant.

Examples & Analogies

Think of SCADA systems like the dashboard in a car. Just as a dashboard provides the driver with crucial information (like speed, fuel level, and engine temperature), SCADA systems give operators the necessary insights to keep track of and control industrial operations, allowing for quick responses to any alerts.

Sensor Networks

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Embedded systems in sensors collect real-time data (e.g., temperature, pressure, humidity) and send it for analysis to optimize operations.

Detailed Explanation

Sensor networks, powered by embedded systems, play a vital role in industrial automation by collecting real-time data regarding various environmental and operational parameters. For example, in manufacturing, sensors might continuously monitor temperature and humidity levels to ensure that conditions are optimal for producing high-quality products. This data is then transmitted to a central system for analysis, enabling timely adjustments to maintain performance levels and enhance production quality.

Examples & Analogies

You can think of a sensor network like a team of security guards monitoring a mall. Each guard (sensor) watches over a specific area (aspect of the operation) and reports anything unusual (data) to a central command center. This helps to ensure that everything runs smoothly and that any potential issues are addressed before they escalate.

Key Concepts

-

Embedded Systems: Integral computing systems in automation enabling specific functionalities.

-

PLCs: Key components for controlling machinery automation and processes.

-

Robotics: Use of embedded systems to increase precision and efficiency in industrial tasks.

-

SCADA Systems: Tools for remote operating monitoring and controlling of industrial processes.

-

Sensor Networks: Collect real-time data crucial for operational intelligence.

Examples & Applications

An industrial robot equipped with embedded systems can accurately perform welding tasks on a production line.

A PLC is programmed to control the assembly of parts in a manufacturing plant, ensuring efficiency and reducing human error.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In factories where machines do work, PLCs and robots, no one is a jerk; with sensors they measure, all day and night, optimizing production, making everything right!

Stories

In a busy factory, a robot named Robby was tasked with welding parts. With his embedded brain, he worked through day and night, automating processes effortlessly and improving output.

Memory Tools

Think of 'S.R.P.' for remembering key applications: S for SCADA, R for Robotics, P for PLCs.

Acronyms

Remember EPIC for the significance of embedded systems

Efficiency

Precision

Innovation

and Cost reduction.

Flash Cards

Glossary

- Embedded Systems

Specialized computing systems integrated into larger systems to perform dedicated functions.

- Programmable Logic Controllers (PLCs)

Industrial computers used for automating processes and controlling machinery.

- Robotics

The branch of technology that deals with the design, construction, operation, and application of robots.

- SCADA

System for remote monitoring and control of industrial processes.

- Sensor Networks

Systems of interconnected devices that collect and transmit data.

Reference links

Supplementary resources to enhance your learning experience.