The Role of Embedded Systems in Industrial Automation

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Industrial Automation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're discussing the role of embedded systems in industrial automation. Can anyone tell me what industrial automation is?

Isn’t it about using technology to control machinery and processes?

Exactly right! Industrial automation involves control systems to operate machinery, which makes processes safer and more efficient. Embedded systems are key components in this by executing specific tasks.

What are some examples of these embedded systems?

Great question! Examples include Programmable Logic Controllers, robotics, and even sensor networks. We'll go into more detail about each of these shortly.

Programmable Logic Controllers (PLCs)

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s dive deeper into Programmable Logic Controllers or PLCs. Can anyone explain what they do?

PLCs control machinery, right? Like they automate processes in factories?

Correct! PLCs automate tasks such as assembly and packaging. Think of them as the brain that manages the machines in a factory. They can adjust processes based on real-time data.

How does that help with efficiency?

By automating tasks, PLCs reduce the time workers spend on repetitive activities, leading to increased productivity and reduced labor costs.

Robotics in Industrial Automation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let’s look at robotics. How do you think embedded systems influence robots in the industry?

I guess they help with precision and control?

Exactly! Embedded systems allow robots to perform tasks like welding or assembly with high precision. They process information in real-time to ensure accurate operations.

What kind of tasks can they perform?

Robots can handle heavy materials, carry out inspections, and even perform maintenance tasks autonomously, significantly reducing the risk of human error.

SCADA Systems and Sensor Networks

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s move on to SCADA systems. How do you think they utilize embedded systems?

They monitor and control processes from a distance, right?

That’s correct! SCADA systems collect data from sensors and enable operators to monitor and control processes remotely. Do you know any examples of where SCADA might be used?

Maybe in utilities like power or water treatment?

Yes! SCADA is vital in managing these services. And speaking of sensors, let’s discuss sensor networks next.

Benefits of Embedded Systems in Automation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

To wrap up, what are the main benefits of using embedded systems in industrial automation?

Increased efficiency and productivity!

And also real-time control to catch issues early!

Exactly! Plus, they help lower production costs through automation and precision. Embedded systems essentially enhance overall operational effectiveness in industrial settings.

This sounds really important for modern manufacturing!

Indeed! The integration of these technologies is essential for advancing industrial automation.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section discusses how embedded systems facilitate industrial automation by controlling machinery, monitoring processes, and enabling real-time data collection. Key applications include Programmable Logic Controllers (PLCs), robotics, SCADA systems, and sensor networks, which together contribute to improved efficiency, productivity, and cost reduction in industrial settings.

Detailed

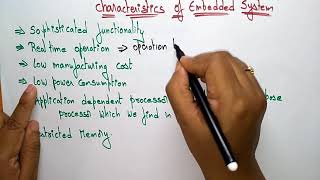

The Role of Embedded Systems in Industrial Automation

Overview

Industrial automation leverages advanced control systems to manage machinery and industrial processes, with embedded systems playing a crucial role in this transformation.

Embedded Systems in Industrial Automation

Embedded systems are utilized across a wide range of applications including:

- Programmable Logic Controllers (PLCs): These systems control industrial machinery by automating tasks like assembly and packaging.

- Robotics: Embedded systems enable robots to execute precise tasks such as material handling, inspection, and assembly operations.

- SCADA Systems (Supervisory Control and Data Acquisition): In SCADA, embedded systems monitor and control industrial processes remotely, essential for operations like power grid management and oil refineries.

- Sensor Networks: These systems collect real-time data from various sensors, such as temperature and pressure sensors, optimizing operations by providing valuable data for analysis.

Significance of Embedded Systems in Industrial Automation

- Efficiency and Productivity: By automating repetitive tasks, embedded systems significantly enhance efficiency and output in manufacturing processes.

- Real-time Control: They provide real-time monitoring which helps prevent issues before they escalate, ensuring smooth operations.

- Cost Reduction: Embedded systems reduce labor costs and error rates, contributing to a decrease in production costs.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Industrial Systems Overview

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Industrial automation refers to the use of control systems, such as computers or robots, to operate machinery and processes. Embedded systems play a key role in controlling and automating these systems.

Detailed Explanation

Industrial automation involves the use of technology, particularly computers and robots, to manage and control industrial processes and machinery efficiently. Embedded systems are crucial in this context because they provide the intelligence and control needed to automate tasks, allowing for more precise and efficient operations. These systems enable industries to improve production rates, enhance product quality, and reduce labor costs.

Examples & Analogies

Imagine a factory where robots are used to assemble cars. Instead of relying on human workers for every task, machines equipped with embedded systems can work continuously, performing repetitive tasks like welding components or painting car bodies. Just like a chef who follows a recipe, an embedded system follows programmed instructions to ensure that each car is made consistently and accurately.

Embedded Systems in Industrial Automation Applications

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Embedded systems are used in a wide range of industrial automation applications, from controlling robotic arms to managing production lines.

- Programmable Logic Controllers (PLCs): PLCs are embedded systems used for controlling industrial machinery, monitoring sensors, and automating tasks like assembly and packaging.

- Robotics: Embedded systems enable robots to perform tasks like material handling, assembly, inspection, and welding with high precision.

- SCADA Systems (Supervisory Control and Data Acquisition): Embedded systems are part of SCADA systems, used to monitor and control industrial processes remotely (e.g., power grids, oil refineries, water treatment plants).

- Sensor Networks: Embedded systems in sensors collect real-time data (e.g., temperature, pressure, humidity) and send it for analysis to optimize operations.

Detailed Explanation

Embedded systems find numerous applications in industrial automation. For instance, Programmable Logic Controllers (PLCs) are specialized computers that manage machinery operations and can react to input from sensors to automate manufacturing processes. Robotics uses embedded systems to carry out tasks with high accuracy, like assembling components or inspecting products. SCADA systems integrate numerous sensors and controllers, allowing operators to monitor and control processes from a distance, which is essential in large industrial environments. Sensor networks constantly gather and send real-time data to improve efficiency and decision-making.

Examples & Analogies

Think of an automated factory as a well-conducted orchestra, where each musician (or machine) plays its part simultaneously under the direction of a conductor (the embedded system). The PLCs act as conductors, ensuring the right tasks are performed at the right time, like a musician playing their instrument precisely when needed. The robots are the musicians executing their parts, while the SCADA system is the audience who monitors the performance, making sure everything runs smoothly.

Significance of Embedded Systems in Industrial Automation

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Embedded systems enable the automation of repetitive tasks, improving efficiency and throughput in manufacturing processes.

- Efficiency and Productivity: Embedded systems enable the automation of repetitive tasks, improving efficiency and throughput in manufacturing processes.

- Real-time Control: Embedded systems provide real-time monitoring and control, ensuring that operations run smoothly and that issues are detected early.

- Cost Reduction: Automation and control via embedded systems reduce labor costs, minimize errors, and lower production costs.

Detailed Explanation

The adoption of embedded systems in industrial automation significantly enhances efficiency and productivity. By automating repetitive activities, these systems allow for continuous operation without breaks, leading to increased output. Real-time monitoring means that any anomalies can be detected and addressed immediately, which prevents costly downtime. Furthermore, implementing embedded systems also reduces labor costs, as fewer workers are needed for manual tasks, and minimizes errors, thus lowering the overall cost of production.

Examples & Analogies

Consider a pizza restaurant that has installed a conveyor belt system to automate the preparation of pizzas. The embedded systems ensure that each ingredient is added in the right amount and at the right time, just like a highly efficient assembly line. This not only speeds up the process but also ensures that each pizza is made consistently without mistakes. The restaurant can produce more pizzas per hour, reducing the cost of production and allowing them to serve more customers efficiently.

Key Concepts

-

Industrial Automation: The integration of control systems to operate machinery and processes, creating safe and efficient environments.

-

Embedded Systems: Essential computing systems embedded within devices to assess conditions and execute tasks.

-

Programmable Logic Controllers: A specialized type of embedded system focused on automating industrial machinery.

-

SCADA Systems: Systems designed for remote monitoring and control of industrial processes to enhance operational efficiency.

-

Robotics: The use of robots in automation, delivering increased precision and efficiency in production tasks.

Examples & Applications

A manufacturing plant uses PLCs to automate the packing process, reducing the amount of labor needed and minimizing errors.

Robotic arms in an assembly line perform precise tasks like screwing and soldering, improving production speed and accuracy.

SCADA systems monitor a water treatment plant's operations, allowing for efficient management of resources and quick reaction to system alarms.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When machines do the work, and robots take the strain, Industrial automation's where efficiency reigns.

Stories

In a busy factory, Billy the Robot used to assemble parts. One day, his friend Sally the Sensor helped him by sending data about parts being ready. Together, they automated the process. Now, they create more products with fewer mistakes!

Memory Tools

Remember 'P-R-S' for automation: Programmable Logic Controllers, Robotics, Sensor networks.

Acronyms

For monitoring, think 'S-C-A-D-A' - Supervisory Control and Data Acquisition.

Flash Cards

Glossary

- Industrial Automation

The use of control systems to operate machinery and processes in various industries.

- Embedded Systems

Computer systems that are integrated into devices to perform dedicated functions.

- Programmable Logic Controller (PLC)

A type of embedded system used to control industrial processes and machinery.

- SCADA (Supervisory Control and Data Acquisition)

A control system used for monitoring and controlling industrial processes remotely.

- Sensor Networks

Networks of embedded systems that collect real-time data from various sensors.

- Robotics

The use of robots to perform tasks that require precision and automation.

Reference links

Supplementary resources to enhance your learning experience.