Industrial Systems Overview

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Industrial Automation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're discussing industrial automation and the critical role embedded systems play in it. Can anyone start by telling me what they think industrial automation refers to?

I think it means using machines instead of people for tasks.

That's right, Student_1! Industrial automation involves control systems, like computers and robots, to operate machinery and processes. It significantly improves efficiency. Can anyone give an example of where we might see this?

Factories where robots do the assembly line work!

Exactly! And embedded systems are at the core of this automation. They allow these machines to function effectively by controlling operations.

What specifically do embedded systems control in factories?

Great question! Embedded systems control everything from robots to the monitoring of production lines. They enhance productivity and ensure that operations run smoothly.

***Summary:*** Today we learned that industrial automation utilizes control systems, like embedded systems, to enhance productivity and efficiency in factories.

Applications of Embedded Systems

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s delve deeper into specific applications of embedded systems in industrial automation. Can anyone start with the term 'Programmable Logic Controllers' or PLCs?

PLCs are the systems that control machinery and automate tasks, right?

Yes! They monitor various sensors and automate tasks like assembly and packaging. What about robotics?

Robots use embedded systems to do specific tasks like handling materials and welding.

Perfect! Now, what do you think SCADA systems are?

They monitor industrial processes from a distance, right?

Exactly! SCADA systems leverage embedded systems to control and monitor operations like power grids. Now, let’s touch on sensor networks.

They gather real-time data to help improve operations?

"Yes, that's crucial! They collect environmental data, which is analyzed to boost efficiency.

Significance of Embedded Systems in Industrial Automation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we’ve discussed applications, let’s focus on the significance of embedded systems in industrial automation. Who can summarize why they're essential?

They improve efficiency and productivity!

Correct! Automation increases throughput greatly. Can anyone give an example of how this might happen?

Like how a conveyor belt can keep moving without breaks, making processes faster.

Absolutely! What about real-time control—why is that significant?

It helps to ensure things are running smoothly and can catch problems early!

Exactly! Embedded systems enable immediate monitoring, which is vital in industrial settings. Lastly, how do embedded systems help in cost reduction?

By reducing labor costs and errors, right?

Correct again! Smoother operations lead to lower production costs. ***Summary:*** Today, we covered the significance of embedded systems—improving efficiency, providing real-time control, and reducing costs.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The Industrial Systems Overview emphasizes how embedded systems are fundamental in automating industrial processes. They are integral to various applications like programmable logic controllers (PLCs), robotics, SCADA systems, and sensor networks that enhance productivity, ensure real-time control, and reduce operational costs.

Detailed

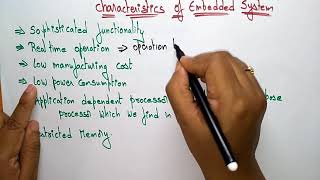

Industrial Systems Overview

Embedded systems are integral to the realm of industrial automation, which involves the use of control systems, including computers and robots, for operating machinery and processes. This section details various applications where embedded systems are employed, illustrating their significance in enhancing efficiency and productivity.

Key Applications:

- Programmable Logic Controllers (PLCs): These are specialized embedded systems designed for controlling industrial machinery and automating tasks like assembly and packaging. They allow for monitoring and implementing control based on input from various sensors.

- Robotics: Embedded systems enable robots to perform tasks such as material handling, assembly, and welding with precision and speed.

- SCADA Systems: Supervisory Control and Data Acquisition systems utilize embedded systems to remotely monitor and control industrial processes, such as power grids and water treatment plants.

- Sensor Networks: Embedded systems within sensor networks gather real-time data on various environmental parameters and relay it for analysis to optimize operational efficiency.

Importance:

- Efficiency and Productivity: Automation through embedded systems markedly enhances manufacturing processes, leading to increased throughput.

- Real-time Control: These systems provide immediate monitoring capabilities that help in maintaining smooth operations and early issue detection.

- Cost Reduction: The application of embedded systems leads to lower production costs, fewer errors, and a decreased need for labor.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Definition of Industrial Automation

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Industrial automation refers to the use of control systems, such as computers or robots, to operate machinery and processes. Embedded systems play a key role in controlling and automating these systems.

Detailed Explanation

Industrial automation is essentially about using technology to control machinery and processes without much human intervention. This means that various tasks in factories and manufacturing setups can be performed automatically with little to no manual input. The role of embedded systems in this context is crucial as they are the 'brains' behind many of these automated systems, allowing them to operate efficiently and effectively.

Examples & Analogies

Think of industrial automation like an automatic coffee machine. You just press a button, and it grinds the beans, brews the coffee, and even pours it into your cup without you having to do much. Similarly, in industrial settings, machinery can operate automatically with embedded systems directing their actions.

Roles of Embedded Systems in Industrial Automation

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Embedded systems are used in a wide range of industrial automation applications, from controlling robotic arms to managing production lines.

Detailed Explanation

In industrial automation, embedded systems take on various roles. They control machines, process data from sensors, and ensure that production lines run smoothly. For example, a robotic arm might be programmed with an embedded system to assemble parts with precision. Similarly, other embedded systems monitor production processes, ensuring everything operates within set parameters, optimizing both performance and safety.

Examples & Analogies

Imagine a factory assembly line where robots work tirelessly to build cars. Each robot has an embedded system that tells it when to pick up a part, where to place it, and when to pass it to the next robot. Just as an orchestra conductor ensures every musician plays in harmony, embedded systems orchestrate the actions of industrial machines perfectly.

Types of Embedded Systems in Industrial Automation

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Programmable Logic Controllers (PLCs): PLCs are embedded systems used for controlling industrial machinery, monitoring sensors, and automating tasks like assembly and packaging. ● Robotics: Embedded systems enable robots to perform tasks like material handling, assembly, inspection, and welding with high precision. ● SCADA Systems (Supervisory Control and Data Acquisition): Embedded systems are part of SCADA systems, used to monitor and control industrial processes remotely (e.g., power grids, oil refineries, water treatment plants). ● Sensor Networks: Embedded systems in sensors collect real-time data (e.g., temperature, pressure, humidity) and send it for analysis to optimize operations.

Detailed Explanation

There are several specific types of embedded systems crucial for industrial automation:

- Programmable Logic Controllers (PLCs): These are specialized computers that automate industrial processes by controlling machinery based on programmed instructions.

- Robotics: Here, embedded systems allow robots to carry out complex tasks with great accuracy, from assembling products to welding parts together.

- SCADA Systems: These enable operators to monitor and control industrial operations from a distance, enhancing flexibility and response times.

- Sensor Networks: Embedded systems in sensors gather and analyze data on various parameters, aiding in maintaining optimal operating conditions and addressing issues swiftly.

Examples & Analogies

Think of a smart home where lights, heating, and security systems work together seamlessly. Similarly, in an industrial setting, PLCs act like the central controller, while robots are the diligent workers executing tasks perfectly, just as a smart device manages your home environment automatically.

Key Concepts

-

Efficiency: The ability to perform tasks with minimal waste of resources.

-

Productivity: The rate at which products are manufactured or services are provided.

-

Real-time Monitoring: Immediate observation and control of processes.

-

Cost Reduction: Decreasing overall operating costs through automation.

Examples & Applications

In a car manufacturing plant, PLCs control the conveyor belts ensuring that each vehicle moves smoothly through the assembly line.

Robot arms equipped with embedded systems can precisely weld car parts, improving the quality and speed of production.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In a factory line, embedded control, makes the processes smooth and whole.

Stories

Imagine a robot named Robo who never gets tired, crafting toys all day with precision. He’s guided by embedded systems, ensuring each toy is perfect, just like the ones kids dream of!

Memory Tools

R.E.C.: Robotics, Efficiency, Cost reductions showcase embedded systems’ magic.

Acronyms

P.S.R.E.

PLC

SCADA

Robotics

Efficiency—key parts of automation!

Flash Cards

Glossary

- Embedded Systems

Specialized computing systems embedded within larger systems for control and automation.

- Programmable Logic Controllers (PLCs)

Embedded systems used for controlling industrial machinery and automating tasks.

- SCADA Systems

Systems that monitor and control industrial processes remotely.

- Sensor Networks

Networks of sensors that collect and relay real-time data for analysis.

- Robotics

Field involving robots that are programmed to perform specific tasks.

Reference links

Supplementary resources to enhance your learning experience.