Significance - 2.5.3

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Efficiency and Productivity

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we'll explore how embedded systems significantly improve efficiency and productivity in industrial automation. Can anyone explain why efficiency is critical in manufacturing?

Efficiency helps to complete tasks faster and increase output.

Exactly! Embedded systems automate repetitive tasks, which not only speeds up production but also reduces labor costs. Remember the acronym APT: Automation, Productivity, Time-saving. What are some tasks that can be automated?

Like assembly lines and quality inspections?

Yes! Great examples. Automation leads to higher quality and less variability in production. Can anyone think of a specific product that benefits from this?

Automated cars, for instance, use embedded systems for assembly.

Wonderful! To summarize, embedded systems increase efficiency and productivity by automating various tasks, which ultimately boosts output.

Real-time Control

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

In this session, let's delve into real-time control. Why do you think it's essential in industrial systems?

To manage processes without delays and respond to issues immediately.

Right on! Real-time control allows operators to detect and resolve issues early, avoiding costly downtimes. Can someone give me an example of how this works?

In a factory, if a machine is about to fail, the embedded system can alert the technician.

Exactly! This preventive approach is crucial. Remember, RAMP: Real-time Alert Monitoring and Prevention. Let's sum it up: embedded systems enhance operational reliability through real-time control.

Cost Reduction

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's explore how embedded systems lead to cost reduction. Can anyone think of how automation might save costs?

It reduces the need for as many workers, which saves on labor costs.

Correct! Additionally, by minimizing errors and streamlining processes, companies can save significantly. Remember the phrase 'Measure Twice, Cut Once'? It illustrates the importance of precision enabled by embedded systems. Can anyone relate this to real-world applications?

Manufacturing robotics decrease mistakes, which means less wasted materials.

Exactly! To wrap up this discussion, embedded systems not only cut labor costs but also enhance resource management, leading to overall reductions in production costs.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Embedded systems are crucial for the automation of industrial processes, significantly enhancing operational efficiency and productivity. This section examines their role in real-time control and cost reduction, showcasing how they enable modern technological advancements in various industrial applications.

Detailed

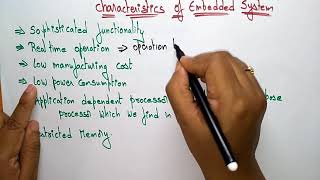

Significance of Embedded Systems in Industrial Automation

Embedded systems play a pivotal role in industrial automation, crucial for the effective control of machinery and processes. Their significance is centered around three main aspects:

1. Efficiency and Productivity

Embedded systems automate repetitive tasks, leading to enhanced efficiency in manufacturing processes. This automation allows for more reliable and faster operations, which in turn increases throughput and maximizes output.

2. Real-time Control

With embedded systems, real-time monitoring and control are possible. They ensure that operations run smoothly and any issues can be detected early, preventing possible downtime or malfunctions in industrial systems.

3. Cost Reduction

Automating tasks with embedded systems reduces labor costs and minimizes errors, leading to lower production costs. By optimizing process management, companies can allocate resources more effectively, resulting in overall cost savings.

In conclusion, the significance of embedded systems in industrial automation can be seen through their impact on efficiency, productivity, and cost-effectiveness, forming the backbone of modern manufacturing strategies.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Efficiency and Productivity

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Embedded systems enable the automation of repetitive tasks, improving efficiency and throughput in manufacturing processes.

Detailed Explanation

This chunk highlights how embedded systems can automate tasks that are often done repeatedly in manufacturing. By using these systems, industries can streamline processes, reducing the need for manual labor and speeding up production. For example, instead of humans manually assembling products, machines controlled by embedded systems can do this faster and more accurately. This not only saves time but also increases the quantity of products that can be made within the same period.

Examples & Analogies

Imagine a car manufacturing plant where robots, equipped with embedded systems, assemble vehicles. Each robot can work tirelessly, performing tasks like welding or painting with precision. By automating these jobs, the plant can produce many more cars in a day than if humans were doing the work alone, akin to how a conveyor belt speeds up the process of getting goods from production to shipping.

Real-time Control

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Embedded systems provide real-time monitoring and control, ensuring that operations run smoothly and that issues are detected early.

Detailed Explanation

This part discusses the ability of embedded systems to monitor factory operations in real-time. This means that as machines are running, embedded systems can check their performance, detect any problems, and send alerts to operators immediately. For example, if a machine starts to overheat, the embedded system can alert a technician to prevent breakdowns, thus maintaining continuous production and enhancing safety.

Examples & Analogies

Think of a smart thermostat in your home. It constantly monitors the temperature and adjusts the heating or cooling in real-time to maintain your desired climate. Similarly, in an industrial setting, an embedded system works like this thermostat but for machinery, ensuring everything operates correctly and efficiently.

Cost Reduction

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Automation and control via embedded systems reduce labor costs, minimize errors, and lower production costs.

Detailed Explanation

This chunk focuses on how using embedded systems not only boosts productivity but also lowers overall costs. By automating tasks, companies can reduce the number of workers needed for certain jobs, which cuts labor costs. Additionally, machines operated by these systems are less prone to making mistakes, which decreases waste and the costs associated with errors.

Examples & Analogies

Consider a bakery that uses an automated system to mix ingredients instead of having staff do it by hand. The machine ensures precise measurements and consistency, which helps avoid mistakes like missing an ingredient. This not only reduces the cost of wasted materials but also allows the bakery to produce more cakes in less time, thus improving their profit margins.

Key Concepts

-

Embedded Systems: Integral to automating industrial processes.

-

Efficiency: Key to maximizing output and minimizing waste.

-

Real-time Control: Enables immediate responses to operational changes.

-

Cost Reduction: Achieves savings through efficient resource management.

Examples & Applications

Programmable Logic Controllers (PLCs) automate complex industrial tasks.

Sensor networks in factories gather data, enabling real-time adjustments to production lines.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In automation’s dance, efficiency leads the chance, with people freed by tech that enhances.

Stories

Imagine a factory where workers are replaced by robots. These robots instantly alert humans about any faults, saving time and money, and ensuring everything runs smoothly.

Memory Tools

For the significance of embedded systems in automation, remember 'E-P-C': Efficiency, Productivity, Cost-reduction.

Acronyms

RAMP for Real-time Alerts and Monitoring Prevention.

Flash Cards

Glossary

- Embedded Systems

Computer systems within larger systems designed to perform dedicated functions.

- Industrial Automation

The use of control systems for operating equipment in industries to minimize human intervention.

- Efficiency

The ability to produce desired outputs with minimal input or waste.

- Realtime Control

The ability of a system to respond to inputs or changes in its environment as they occur, in real-time.

- Cost Reduction

The process of decreasing expenses associated with production, labor, and management.

Reference links

Supplementary resources to enhance your learning experience.