Introduction to Thermal Desorption

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Fundamentals of Thermal Desorption

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Welcome everyone! Today, we are going to explore thermal desorption, a fascinating method that allows us to analyze volatile compounds in various samples. Can anyone tell me what thermal desorption involves?

Is it about heating samples to release gases?

Exactly! When we heat the samples, what happens to the volatile components?

They are desorbed and become gas, right?

Correct! This is critical when analyzing substances in methods like gas chromatography. Quick desorption ensures we maintain the integrity of the sample. This is known as flash desorption. Can anyone summarize why quick desorption is advantageous?

It helps in injecting the sample as a pulse, which makes analysis more accurate.

Well said! A good mnemonic to remember this is 'FAST'—Flash desorption Allows Sample Testing efficiently. Let's move on to how we connect these processes.

Connection to Gas Chromatography

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we understand thermal desorption, let’s discuss how it interacts with gas chromatography, or GC. What is the role of the carrier gas in this context?

Doesn't the carrier gas help to transport the desorbed gases into the GC?

Absolutely! Typically, we use gases like argon, helium, or nitrogen. Why is it important to use the same carrier gas in both thermal desorption and GC?

To avoid mixing contaminants that could affect the results?

Exactly! Maintaining sample purity is crucial. Remember: 'SIMPLE'—Same In Methodology for Pure Lab Effect. Now, what about the sample loop in GC?

The sample loop holds the sample for accurate measurement, I think.

Correct! Accurate volume measurement is essential to get reliable data. Now let’s summarize our learnings.

Calibration and Challenges with Thermal Desorption

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s talk about calibration in thermal desorption. Why is calibration so important?

To ensure that the readings we get correspond to the actual concentrations in the sample?

Exactly! We calibrate our equipment to match known concentrations. What challenges might arise during this process?

If we don't properly account for the sample volume, the results could be inaccurate.

Correct again! Always consider the specifics of each sample. Maybe remember 'CARES'—Calibration Accounts for Real-World Environmental Samples. Any questions before we proceed to applications of thermal desorption?

Applications in Environmental Monitoring

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Applying thermal desorption, especially in analyzing volatile organic compounds, is critical in environmental monitoring. Can anyone think of a situation where this might be used?

Maybe testing for pollutants in water or air samples?

Spot on! This is particularly useful for compounds like benzene or toluene. Can anyone summarize how thermal desorption aids in tracking VOCs?

It helps us extract these compounds quickly and accurately for analysis!

Excellent! Remember 'VOCS'—Volatile Organic Compounds Separate easily through this method. Now, let’s discuss the purge-and-trap method.

Emerging Techniques: Passive Sampling

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Lastly, let's explore passive sampling as an emerging technique. How is this different from active sampling?

Active sampling uses a pump, while passive sampling does not, right?

That's right! Passive samplers work by coming to equilibrium with the surrounding atmosphere. Why might this be beneficial in certain situations?

It reduces the need for equipment and can be placed in many locations without much hassle.

Exactly! Think of the mnemonic 'EASE'—Equilibrium Achieves Sampling Efficiency. In which scenarios would you prefer passive sampling versus active?

In remote locations where power supply is an issue!

Perfect answer! Always remember to assess the sample contexts when choosing your method. Let's review our entire section.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section discusses the procedure of thermal desorption, detailing how samples are heated to release volatile organic compounds (VOCs) for analysis. It emphasizes the importance of rapid desorption and the use of a gas chromatography (GC) system for subsequent analysis, as well as applications in environmental monitoring.

Detailed

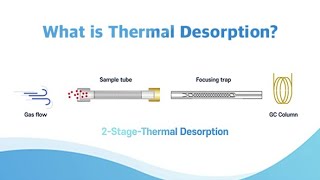

Introduction to Thermal Desorption

Thermal desorption is a critical technique in environmental monitoring and chemical analysis, allowing for the extraction of volatile compounds from samples such as air or water. The basic process involves placing a sample in a thermal desorption tube, which is then connected to an analytical instrument, often a gas chromatograph (GC).

Key Points:

- Sample Preparation: Samples are placed in a tube and connected to a pump leading to an automated thermal desorption unit.

- Heating: The tube is heated rapidly (flash desorption) to release all adsorbed compounds in a pulse, essential for obtaining accurate analyses compatible with GC.

- Carrier Gas: A carrier gas (e.g., argon, helium, nitrogen) is used to sweep the volatile compounds into the GC, facilitating efficient analysis.

- Sample Loop: The GC sample loop holds the desorbed sample for accurate measurement, highlighting the importance of precise volume control in chemical analysis.

- Calibration: Various factors are considered for calibration to ensure accurate concentration measurements.

- Applications: Particularly useful for detecting volatile organic compounds (VOCs) in air and water samples, effectively minimizing sample loss through processes like purge and trap methods.

- Passive Sampling: New methods in passive sampling derive average concentration measurements without mechanical pumps, which may be impractical in certain settings.

This section illustrates how thermal desorption integrates with chemical engineering principles, streamlining processes for quality control and assurance in environmental and chemical analysis.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Overview of Thermal Desorption

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

So, while coming back to our thermal desorption what is done is the following. So, you take your sample in a tube, you attach it to a pump in the usual way and then this tube is brought to what is called now called as an automated thermal desorption unit. It is an accessory to a GC, it is kept before a GC. It doesn’t have to be a GC, it can be anything, any analytical instrument; it is an accessory before an analytical instrument for processing.

Detailed Explanation

Thermal desorption is a method used in analytical chemistry to extract volatile substances from a solid or liquid. You start by placing your sample in a tube connected to a pump. This setup is then connected to an automated thermal desorption unit, which serves as an accessory to a Gas Chromatograph (GC), but can also work with other analytical instruments. The main function of this unit is to prepare and process the sample before it undergoes analysis.

Examples & Analogies

Think of thermal desorption like a coffee filter in your morning routine. Just as you put ground coffee into a filter and use hot water to extract the flavors into your cup, in thermal desorption, we use heat to extract volatile compounds from the sample, preparing a 'flavorful' extract for analysis.

Process of Thermal Desorption

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

This thermal desorption tube is placed in a heated chamber and it needs to go to an analytical instrument. So, let us say it needs to go to a GC for example. This tube, when you heat it to a very high temperature, what will happen is, it will all come out; the desorption will happen, but it can’t stay there; it has to be taken out quickly.

Detailed Explanation

In the thermal desorption process, the sample tube is heated to high temperatures, causing the volatile components to evaporate or 'desorb' from the sample. However, it is crucial that these vapors are swiftly moved out of the tube and into the next stage of analysis. This rapid removal ensures that the sample does not linger, which could otherwise lead to inaccurate results.

Examples & Analogies

Imagine boiling a pot of water: if you leave the lid on for too long, the steam (representing the volatile compounds) will condense back into the water instead of escaping. To ensure that the steam (or in this case, the desorbed compounds) moves on to be measured, you need to remove it quickly just like you would take the lid off swiftly.

Importance of Flash Desorption

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

So, what we do is flash desorption. Flash desorption means it is very quick; it happens very quickly, the temperature shoots up very fast and everything comes off in one shot. If you are increasing temperature slowly little by little, it will come the adsorption as of changing slowly but you want all of it to come at once.

Detailed Explanation

Flash desorption is a technique that enables rapid desorption of sample components. By quickly raising the temperature, it allows all the volatile components to evaporate almost instantaneously. This is crucial because it helps maintain the integrity of the sample and reduces the chance of any components re-adsorbing back onto the tube walls caused by slower temperature increases.

Examples & Analogies

Consider how a pressure cooker works. When you increase pressure quickly, steam is released all at once when you open it. If you had increased the pressure slowly, the steam would have escapes only gradually, possibly leading to some getting trapped inside. Flash desorption works similarly, ensuring that everything is efficiently released in one go.

Use of Sweep Gas in Thermal Desorption

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

There is usually a sweep gas, essentially that’s what it does, it sweeps it; whatever is now desorbed gets flushed out. This is usually the carrier gas that is used in the GC; you don’t want something else mixing with it; you are using argon or helium or nitrogen there, you use the same thing here.

Detailed Explanation

A sweep gas is used to carry away the vapors that are desorbed. In this context, the sweep gas can be argon, helium, or nitrogen, and it plays an essential role in ensuring that the sample is efficiently transported to the next stage of analysis, reducing contamination and improving the quality of results.

Examples & Analogies

Think of a vacuum cleaner: just like it pulls dust and debris out of a carpet and into a bag, the sweep gas effectively pulls the desorbed compounds out of the thermal desorption unit to ensure they reach the analytical device.