Polymers: Structure-Property Relationships and Applications

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Mechanical Properties of Polymers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we’ll explore the mechanical properties of polymers. Can anyone remind me of what tensile strength means?

Isn't it about how much force a material can withstand before it breaks?

Exactly! Tensile strength indicates how much stress a polymer can endure without failing. It’s derived from stress–strain curves. Can anyone tell me why different polymers have varying tensile strengths?

It must have to do with their structure, like crystallinity and molecular weight?

Correct! Higher molecular weight and crystallinity often lead to greater tensile strength but can reduce elongation. What does high elongation indicate?

That the material can stretch a lot before breaking?

Precisely! A polymer with high elongation, like LDPE, can be stretched extensively without breaking. As we summarize, remember that high crystallinity polymers can be stiff and strong, but with low elongation, they may be more prone to brittleness.

Thermal Properties and Processing Techniques

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s discuss the thermal properties of polymers. What is the significance of glass transition temperature, or Tg?

I think it’s the temperature where the polymer changes from a brittle state to a rubbery state?

Exactly! Tg is critical for processing thermoplastics. What about the melting temperature, Tm, and why is it important during processing?

Tm is the point where crystalline regions melt, allowing the polymer to flow.

Right! For semi-crystalline polymers, we often need to process between Tg and Tm. Can anyone share an example of a processing method used for polymers?

Extrusion is a method where melted polymer is forced through a die to shape it.

Fantastic! Processing methods such as extrusion or injection molding must be done at temperatures above Tg to ensure proper flow. To sum up, understanding these thermal transitions is crucial when designing components from polymers.

Applications of Polymers Based on Classes

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s turn our attention to applications. Can anyone name a common polymer used for packaging materials?

Polyethylene is widely used for packaging, right?

Correct! Both LDPE and HDPE have distinct properties that make them suitable for various packaging needs. How about textiles?

Nylon and polyester are popular in clothing and upholstery.

Exactly! Each polymer class serves specific requirements in its application. For instance, which polymers would you suggest for automotive parts?

I think polycarbonate is great because it's tough and can withstand impact.

Well said! As a summary, polymers are uniquely suited to diverse applications based on their structure and properties, from packaging and textiles to engineering and biomedical fields.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

In this section, we explore how the mechanical properties of polymers, including tensile strength, elongation, thermal properties, and viscosity, affect their processing methods and applications. We also categorize how different classes of polymers are utilized across various industries, from packaging materials to biomedical applications.

Detailed

Polymers: Structure-Property Relationships and Applications

This section delves into the intricate relationship between the structure and properties of polymers and their various applications in the real world. We begin by examining mechanical properties through stress–strain curves, noting how crystallinity, molecular weight, and cross-linking influence tensile strength, elongation, and modulus. For example, polymers like HDPE demonstrate high tensile strength and stiffness due to their high crystallinity, but they exhibit low elongation, leading to potential brittleness. Conversely, amorphous polymers like LDPE provide high elongation but lower tensile strength.

Next, we discuss the thermal characteristics of polymers, focusing on glass transition temperature (Tg), melting temperature (Tm), and degradation temperature. The processing of thermoplastics typically occurs above Tg to facilitate chain mobility, while thermal degradation is a significant concern when operating at elevated temperatures.

The section further addresses the viscosity and melt flow of polymers during processing techniques like extrusion, injection molding, and blow molding. Understanding the non-Newtonian flow characteristics of molten polymers is crucial to ensure successful processing and end-product performance.

Finally, we transition into applications based on polymer types, identifying how diverse classes of polymers meet specific functional requirements in various sectors such as packaging, textiles, automotive, and biomedicine. This comprehensive overview emphasizes the importance of structure-property relationships in the innovative design and application of polymer materials.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Mechanical Properties and Processing

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Tensile strength, elongation, modulus

- Defined by stress–strain curves obtained from tensile testing. The shape of these curves depends on polymer crystallinity, crosslinking, molecular weight, and plasticizers.

- High-molecular-weight, highly crystalline polymers (e.g., HDPE, nylon 6,6) exhibit high tensile strength and stiffness (high modulus), but low elongation at break (brittle behavior if too crystalline).

- Amorphous, lightly crosslinked, or lightly crystalline polymers (e.g., LDPE, elastomers like natural rubber) can be stretched extensively (high elongation) but have lower tensile strength.

Detailed Explanation

The section on mechanical properties explains how the strength and flexibility of polymers are measured using tensile strength and elongation tests. Tensile strength refers to a material's ability to resist being pulled apart before it breaks, while elongation measures how much it can stretch before breaking. The behavior of different polymers can vary greatly based on their structure. For example, polymers like high-density polyethylene (HDPE) and nylon 6,6 are very strong and stiff but can break easily if stretched too far. In contrast, materials like low-density polyethylene (LDPE) and natural rubber are much more flexible and can stretch significantly but are not as strong.

- In summary, the mechanical properties are influenced by the arrangement of the polymer chains (crystallinity), how the polymer is processed (crosslinking), the molecular weight of the molecules, and the presence of additives like plasticizers that make the material softer and more flexible.

Examples & Analogies

Think of a rubber band versus a piece of glass. A rubber band can stretch a lot before it snaps, demonstrating high elongation but lower tensile strength. On the other hand, glass is very strong but can break quickly when stretched or hit; it has high tensile strength but low elongation. This differentiation in how materials respond to stress is crucial, whether you're making durable tires or stretchy clothing.

Thermal Properties: Tg, Tm, Thermal Degradation

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Thermal properties (Tg, Tm, thermal degradation)

- Glass transition (Tg) marks softening point for amorphous regions. Thermoplastic processing must be above Tg to allow chain mobility.

- Melting temperature (Tm) is where crystalline domains melt. For semi-crystalline polymers, processing is often between Tg and Tm, where the material flows but retains some order.

- Thermal degradation starts at higher temperatures (often above 200–300 °C for polyolefins; above 400 °C for aromatic polymers). Additives (antioxidants, stabilizers) can raise degradation onset.

Detailed Explanation

This part discusses the thermal properties of polymers, particularly the glass transition temperature (Tg) and melting temperature (Tm). Tg is the temperature at which the polymer changes from a hard and glassy state to a soft and rubbery state. This is crucial for processing polymers because it influences how they can be shaped and used in manufacturing. Tm is the temperature at which crystalline portions of the polymer begin to melt, allowing the material to flow.

Thermal degradation describes the breakdown of polymers when subjected to high temperatures, which can significantly affect their integrity and usability. For instance, many plastics can start to decompose when temperatures exceed 200–300 °C, but some more heat-resistant polymers can withstand higher temperatures. Additives are often included in polymer formulations to improve stability and delay degradation

Examples & Analogies

Imagine a stick of butter left out in the sun. At room temperature, it softens, similar to how a polymer passes the Tg, becoming pliable. If you then heat it further, it will eventually melt and lose structure entirely, analogous to reaching Tm. If you cooked it on high heat for too long, it could burn or break down just like thermal degradation indicates, resulting in a completely unusable product.

Viscosity and Melt Flow

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Viscosity and melt flow

- Molten polymers exhibit non-Newtonian, shear-thinning behavior. Viscosity depends strongly on molecular weight (η ~ MW^3.4 for linear polymers). High-molecular-weight polymers are difficult to process, so blends of different molecular weights or plasticizers can be used.

Detailed Explanation

This section defines viscosity and melt flow in molten polymers. Viscosity refers to how thick or thin a liquid is; in the case of molten polymers, it describes how easily they can be processed. Non-Newtonian behavior means that the viscosity of the polymer changes under different conditions, such as when force is applied. For example, some polymers might flow easier (have lower viscosity) when they are pushed or stirred hard (shear-thinning).

The molecular weight of the polymer significantly impacts viscosity. As molecular weight increases, viscosity typically increases as well, making high-molecular-weight polymers harder to work with. To manage this, manufacturers often use blends of different molecular weights or add plasticizers to reduce viscosity and improve processability.

Examples & Analogies

Consider honey versus water. Honey is thicker (higher viscosity) than water, making it much slower to pour. The thicker consistency makes it harder to move quickly, similar to high-molecular-weight polymers. If you want honey to flow better, you might warm it up or mix it with a bit of water. Similarly, in manufacturing, adding plasticizers can make thick polymers easier to handle.

Processing Techniques

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Processing techniques

- Extrusion: Polymer melt forced through a die to form continuous profiles (pipes, films, sheets, fibers). Cooling sets the shape.

- Injection molding: Polymer melt injected into a closed mold; cooling yields intricate parts (automotive parts, containers, housings).

- Blow molding: Melted tube (parison) is inflated inside a mold with air to form hollow objects (bottles, drums).

- Compression molding: Polymer placed in heated die cavity; pressure applied to shape material (thermosets like Bakelite, rubber products).

- Casting (solution or bulk): Polymer is dissolved or melted, poured into a mold, and allowed to set (e.g., acrylic castings, epoxy resins).

- Fiber spinning: Polymer solutions or melts extruded through spinnerets, cooled or coagulated to form fibers (nylon, polyester, acrylic).

Detailed Explanation

The processing techniques outlined show how polymers are turned into finished products. Extrusion is a method where molten polymer is forced through a shape (die) to make continuous lengths, such as pipes. Injection molding allows intricate shapes to be made by injecting molten polymer into molds, which cool and harden into final products. Blow molding creates hollow items like bottles by inflating melted polymer in a mold. Compression molding is used for thicker materials like thermosets, while casting involves pouring polymer into a mold and letting it harden. Lastly, fiber spinning extrudes fibers, which can be used for textiles and other applications.

Examples & Analogies

Think of making pasta. When you put dough through a pasta maker, it’s like extrusion; the dough is forced through a shape to create spaghetti. Injection molding is like filling a muffin tin; you pour batter into each mold, and once baked, the muffins take on the shape of the tin. Blow molding resembles blowing up a balloon; you fill it with air until it takes on a new shape. Just as various methods produce different pasta shapes and types, these techniques shape polymers into many different products.

Applications Based on Polymer Classes

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Applications Based on Polymer Classes

- Packaging materials

- Polyethylene (PE): Film packaging (LDPE), rigid containers (HDPE). Excellent moisture barrier, low cost, light weight.

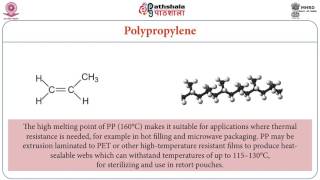

- Polypropylene (PP): Food containers, medicine bottles; good chemical resistance, higher temperature tolerance than PE.

- Polyethylene terephthalate (PET): Bottles for carbonated beverages, fiber for clothing (polyester), clear, strong, good gas barrier.

Detailed Explanation

This section outlines the various applications of different classes of polymers, particularly in packaging materials. Polyethylene (PE), both low-density (LDPE) and high-density (HDPE), is widely used in packaging due to its excellent moisture barrier qualities and low cost. Polypropylene (PP) is used for food containers and medicine bottles, and it can handle higher temperatures than PE. Polyethylene terephthalate (PET) is commonly used for carbonated beverage bottles and fibers for clothing due to its strength and clarity.

These polymers are essential in everyday life, providing lightweight, durable, and versatile options for a wide range of products.

Examples & Analogies

Imagine going to a grocery store. The plastic bags holding your vegetables are likely made from polyethylene, which protects the food from moisture and makes it easy to carry. Your drink could come in a PET bottle, designed to withstand the carbonation pressure while still being lightweight and transparent for easy viewing. These materials are chosen not just for their functionality but also for their cost-effectiveness, making them staples of modern packaging.

Key Concepts

-

Mechanical Properties: The strength and deformation characteristics of polymers, including tensile strength and elongation.

-

Thermal Properties: Tg and Tm determine how polymers behave under heat and are critical for processing.

-

Processing Techniques: Methods of reshaping polymers, which can be influenced by their thermal and mechanical properties.

-

Applications of Polymers: Different industries utilize various polymer types based on their unique structures and properties.

Examples & Applications

High-density polyethylene (HDPE) is used for making strong plastic bottles because of its high tensile strength.

Nylon is widely used in textiles for its durability and stretch properties.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

If you want PE in your pack, make sure it’s strong and not slack!

Stories

Once upon a time in Polymer Land, HDPE was the strongest knight with high tensile strength, while LDPE, the flexible one, stretched to help others but could break if pushed too far.

Memory Tools

Remember: Tm means 'Melting Time' and Tg is 'Glassy Transition'—think Tm for melting ice and Tg for glassy winter.

Acronyms

M.E.T.P. = Mechanical properties, Elasticity (elongation), Thermal properties, Processing methods.

Flash Cards

Glossary

- Tensile Strength

The maximum amount of tensile stress that a material can withstand before failure.

- Elongation

The ability of a material to stretch before breaking, expressed as a percentage change in length.

- Modulus

A measure of a material's stiffness or resistance to deformation under load.

- Glass Transition Temperature (Tg)

The temperature range in which a polymer transitions from a brittle or glassy state to a rubbery state.

- Melting Temperature (Tm)

The temperature at which crystalline regions of a polymer melt, allowing for flow and reshaping.

- Thermoplastic

A type of polymer that softens upon heating and hardens upon cooling, allowing for reshaping.

- Thermoset

A polymer that becomes irreversibly hardened during the curing process; it cannot be remolded.

Reference links

Supplementary resources to enhance your learning experience.