Components and Architecture of Robotic Assembly Systems

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Hardware Components

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we are discussing the hardware components of robotic assembly systems. Can anyone tell me what a manipulator arm does?

Isn't it the part that allows the robot to move and do tasks?

Exactly! The manipulator arm is responsible for performing complex motions. It enables the robot to perform tasks like welding and assembly. Now, what do you think end effectors are?

They must be the tools that the robot uses to interact with objects, right?

That's correct! End effectors include grippers and suction cups depending on the task. Now, can anyone explain why sensors are important?

I assume they help the robot understand its environment and avoid obstacles?

Spot on! Sensors allow robots to have situational awareness, crucial for safe operation. Finally, who can tell me what mobile platforms do?

They probably help the robot move around the construction site?

Yes, they enhance navigation for the robot! To summarize, the hardware components of robotic assembly systems include manipulator arms, end effectors, sensors, and mobile platforms.

Software Systems

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let’s shift gears to discuss software systems in robotic assembly. First, can someone explain what control algorithms do?

Are they the instructions that tell the robot what to do?

Great start! Control algorithms guide real-time decision-making and path planning for robots. They ensure accuracy during operations. What about CAD/CAM integration, does anyone know its significance?

It converts design data into something the robot can understand, right?

Exactly! It enhances the efficiency of the workflow from design to execution. Now, what do you think a digital twin is?

Is it like a virtual model of the robot that helps simulate tasks?

Correct! Digital twins help simulate and optimize operations, allowing for better planning. To wrap up, we’ve learned about control algorithms, CAD/CAM integration, and digital twins, all of which are essential for robotic assembly systems.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

In this section, we explore the critical hardware components, including manipulator arms, end effectors, sensors, and mobile platforms, alongside the software systems like control algorithms and CAD/CAM integration that enable robotic assembly systems to operate effectively in construction.

Detailed

Components and Architecture of Robotic Assembly Systems

Overview

Robotic assembly systems in construction comprise a variety of hardware and software components that work together to automate tasks. This section will discuss key hardware elements, including the manipulator arm, end effectors, sensors, and mobile platforms, and examine the essential software systems such as control algorithms and CAD/CAM integration. These components collectively enhance efficiency, precision, and safety in construction processes.

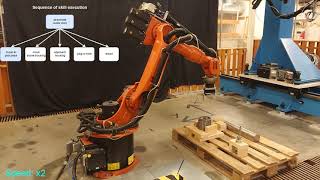

1. Hardware Components

- Manipulator Arm: A multi-axis robotic arm that allows for complex movements necessary for tasks like welding and assembly.

- End Effectors: Specialized tools like grippers, suction cups, and welders designed for specific tasks involving material handling and manipulation.

- Sensors: Devices such as vision systems, force sensors, and proximity detectors provide situational awareness for adapting to environmental conditions.

- Mobile Platforms: Autonomous or remote-controlled bases that enhance on-site navigation and operational versatility.

2. Software Systems

- Control Algorithms: These algorithms enable real-time decision-making and path planning, guiding robotic movements and actions with precision.

- CAD/CAM Integration: This process converts Computer-Aided Design (CAD) data into executable instructions for the robot, enhancing workflow efficiency.

- Digital Twins: These virtual replicas of physical systems allow for simulation and optimization of robotic assembly operations, significantly improving planning and execution.

Significance

Understanding the components and structure of robotic assembly systems is critical, as it establishes a foundation for exploring advanced robotic applications in the construction industry, ultimately driving innovation and improving productivity.

Youtube Videos

![How to get started with Robotics? [MUST KNOW TIPS] Building Robots for Beginners](https://img.youtube.com/vi/NRj6gzah7JA/mqdefault.jpg)

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Hardware Components of Robotic Assembly Systems

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Hardware Components

- Manipulator Arm: Multi-axis robotic arm for performing complex motions.

- End Effectors: Specialized tools (grippers, suction cups, welders) depending on the task.

- Sensors: Vision systems, force sensors, proximity detectors for situational awareness.

- Mobile Platforms: Autonomous or remote-controlled bases for on-site navigation.

Detailed Explanation

This chunk covers the hardware components essential for robotic assembly systems. The manipulator arm is crucial because it allows robots to perform precise movements, making them capable of handling intricate tasks. End effectors are tools that attach to the manipulator arm and can vary based on the job—like grippers for picking up objects or welders for joining materials. Sensors provide the robot with information about its environment, aiding in making decisions about movement and operation. Finally, mobile platforms let robots navigate construction sites autonomously or through remote control, enabling them to perform tasks in various locations efficiently.

Examples & Analogies

Think of a robotic assembly system like a human hand. The manipulator arm acts as the arm, moving to different locations. The end effectors are like fingers, adapting to pick up different objects like tools or food. Sensors function similarly to our eyes, helping the robot to understand what's around it. Finally, the mobile platforms are like our legs, allowing the robot to move from one place to another.

Software Systems in Robotic Assembly

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Software Systems

- Control Algorithms: For real-time decision-making and path planning.

- CAD/CAM Integration: Converts design data into executable robotic instructions.

- Digital Twins: Virtual replicas of physical systems for simulation and optimization.

Detailed Explanation

The software component of robotic assembly systems is vital for their operation. Control algorithms provide the logic that allows robots to make decisions on-the-fly, optimizing their movements and actions for efficiency. The CAD/CAM integration means that designs made in software can be translated into commands for the robot, ensuring that the physical work matches the intended design accurately. Digital twins are virtual models of the robotic systems that allow engineers to simulate and test performance without using the physical robot, which can save time and resources in the design stage.

Examples & Analogies

Imagine planning a road trip. The control algorithms are like a GPS guiding you in real time, telling you the best route to take. CAD/CAM integration is like converting your travel plans into actionable directions. Lastly, think of digital twins like a video game simulator; it lets you practice your route before actually hitting the road, helping you to refine your plan without the hassle of real-life trial and error.

Key Concepts

-

Manipulator Arm: A device allowing complex movements for various construction tasks.

-

End Effectors: Tools attached to robots for specific functions such as handling or welding materials.

-

Sensors: Essential components that provide environmental awareness to robotic systems.

-

Mobile Platforms: Bases that allow robots to navigate construction sites, adapting to different terrains.

-

Control Algorithms: Software that guides robotic behavior and decision-making in real-time.

-

CAD/CAM Integration: The process of converting design data into executable robotic instructions.

-

Digital Twins: Virtual representations of physical systems enabling simulation and optimization.

Examples & Applications

A manipulator arm used in robotic welding systems to ensure precision in joining metal components.

End effectors like grippers used in warehouse robots for picking and placing items.

Sensors that detect obstacles in a robot's path, enabling safer navigation on a construction site.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In assembly, arms and tools do play, sensors guide them through the day.

Stories

Imagine a robot named 'Robo' that had a strong arm and clever tools. Every day, Robo would go to work and use its sensors to navigate the busy construction site, ensuring that everything was built perfectly!

Memory Tools

Remember 'MESC' - Manipulator, End Effectors, Sensors, Control algorithms as the essentials of robotic systems.

Acronyms

For software components, think 'CAD/D' for *CAD/CAM Integration* and *Digital Twins*.

Flash Cards

Glossary

- Manipulator Arm

A multi-axis robotic component that performs complex movements.

- End Effectors

Specialized tools attached to a robot, designed for specific tasks such as gripping or welding.

- Sensors

Devices that provide situational awareness to a robot, such as vision systems and proximity detectors.

- Mobile Platforms

Autonomous or remote-controlled bases that allow robots to navigate construction sites.

- Control Algorithms

Programs that enable robots to make real-time decisions and plan their movements.

- CAD/CAM Integration

The combination of Computer-Aided Design and Computer-Aided Manufacturing data to create executable instructions for robots.

- Digital Twins

Virtual copies of physical systems used for simulation and optimization.

Reference links

Supplementary resources to enhance your learning experience.

- Introduction to Robotic Manipulators

- Understanding End Effectors in Robotics

- Importance of Sensors in Robotics

- Mobile Robots: An Overview

- Control Algorithm Basics in Robotics

- CAD and CAM Integration for Robotics

- Digital Twin Technology and Applications

- Mobile Platforms in Robotics Design

- Robotic End Effectors: A Comprehensive Guide