APPLICATIONS OF ELASTIC BEHAVIOUR OF MATERIALS

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Elastic Behaviour Applications

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're diving into the applications of elastic behaviour in engineering. Why do you think it's crucial for engineers to understand how materials will behave under stress?

Maybe because it helps prevent buildings from collapsing?

Exactly! Understanding elasticity helps ensure structures can support loads without permanent deformation. Can anyone give an example of where this might be important?

Cranes lifting heavy loads need strong ropes that don’t stretch too much.

Right! We need ropes that can handle heavy loads while remaining within their elastic limits. Let's remember the acronym 'S.P.A.C.E' - Structures, Properties, Applications, Calculations, and Engineering - to keep these points in mind.

S.P.A.C.E is a good way to remember the key factors!

Great feedback! Remembering our framework helps us view the challenges engineers face.

Materials in Structural Engineering

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s consider how different materials — like steel and concrete — impact structural design. Why do you think architects choose steel for tall buildings?

I think steel is strong and allows buildings to rise higher without collapsing!

Correct! Steel has a high Young’s modulus, meaning it can withstand a lot of stress. What's the significance of a beam having a wide base, like in a bridge?

A wide base helps distribute weight better and reduces bending under load!

Excellent point! Remember the saying 'Wider is Better' when designing beams and structures. It echoes the need for adequate load distribution.

Real-World Applications and Design Considerations

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's talk about cranes. How do we determine the thickness of the steel rope used in cranes based on elastic properties?

We have to ensure it doesn’t stretch beyond its elastic limit when lifting heavy loads!

Exactly! If the extension exceeds the elastic limit, it could break or deform permanently. Remember, the formula used is Area ≥ Weight/Yield Strength. Can anyone recall a similar concept from other materials or applications?

Like the I-beam shape that helps bridges carry loads efficiently!

Yes! The I-beam shape maximizes strength while minimizing weight. That's a practical application of understanding material properties and elasticity!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The elastic behavior of materials is crucial for various engineering applications. It influences the design of structures like buildings and bridges, as well as components used in machinery. Knowledge of material properties such as Young's modulus assists engineers in choosing the right materials and designing safe structures.

Detailed

Applications of Elastic Behaviour of Materials

Understanding the elastic behavior of materials is essential in many engineering fields. This section discusses how such knowledge applies to practical situations:

- Engineering Design: The successful design of buildings, bridges, and other infrastructures depends heavily on the elastic properties of materials such as steel and concrete. Understanding how these materials behave under stress allows engineers to calculate potential deformations and ensure stability.

- Mechanical Components: For functionality and safety, many mechanical components such as cranes and ropes must operate within the elastic limits of their materials to prevent permanent deformation.

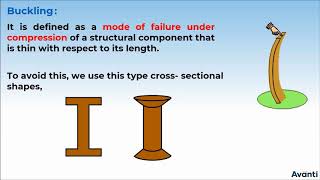

- Structural Shapes: The cross-sectional shapes of structural elements (such as beams) are often designed with elastic properties in mind to maximize strength and minimize weight.

- Real-Life Scenarios: Everyday applications, from the design of bridges to cranes, highlight the importance of knowing how materials react to stresses and loads. The elastic properties inform decisions that protect structural integrity while meeting functional requirements.

These applications underline how fundamental principles of elasticity shape our built environment and enhance safety and efficiency in engineering.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Importance of Elastic Behaviour in Engineering

Chapter 1 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The elastic behaviour of materials plays an important role in everyday life. All engineering designs require precise knowledge of the elastic behaviour of materials.

Detailed Explanation

Elastic behaviour refers to how materials deform under stress and return to their original shape after the stress is removed. This property is crucial for engineers when they design structures like buildings and bridges. Understanding how different materials react to various forces helps in making safe and efficient designs.

Examples & Analogies

Think about how a rubber band stretches when you pull it. When you let go, it goes back to its original shape. Engineers consider similar principles when using materials like steel or concrete, which behave elastically up to a certain point. Imagine trying to build a bridge using a material that doesn't return to its shape; it would fail under the weight of cars!

Design Considerations in Building Structures

Chapter 2 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

For example, while designing a building, the structural design of the columns, beams and supports require knowledge of strength of materials used.

Detailed Explanation

When engineers design buildings, they need to ensure that columns, beams, and supports can withstand forces such as the weight of the building itself and any additional loads like wind or people. This requires detailed calculations involving the elastic properties of materials like concrete and steel, ensuring they can bear the loads without permanent deformation.

Examples & Analogies

Imagine stacking books on a table. If the table's legs (the supports) are too weak, they might buckle under the weight, collapsing the table. Similarly, if the materials in a building's columns and beams are not strong enough, the entire structure might be at risk of collapse.

Applications in Cranes and Lifting Equipment

Chapter 3 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Cranes used for lifting and moving heavy loads from one place to another have a thick metal rope to which the load is attached.

Detailed Explanation

Cranes rely on the elasticity and strength of materials to lift heavy loads. The metal rope must be thick enough to support the weight without exceeding its elastic limit, meaning it shouldn't stretch permanently when a heavy load is applied. Engineers calculate the necessary thickness of the rope based on the expected loads to ensure safety and functionality.

Examples & Analogies

Consider a swing hanging from a tree branch. If the rope is thin and you try to swing with a heavy friend, the rope may snap. But if you have a thick, strong rope, it can safely hold both of you without breaking. Similarly, crane ropes must be designed to handle specific weights without failing.

Designing Beams to Minimize Bending

Chapter 4 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

A beam should not bend too much or break. Let us consider the case of a beam loaded at the centre and supported near its ends.

Detailed Explanation

When a beam supports weight, it can bend under the pressure, which could compromise its structural integrity. Engineers use formulas to calculate how much bending will occur under a given load, allowing them to design beams that are stronger and less prone to bending by selecting the right materials and shapes.

Examples & Analogies

Think of a trampoline. When you jump on it, the surface bends downwards due to your weight. A well-designed trampoline distributes this weight evenly and springs back to its original shape. In construction, beams are designed with similar principles to ensure they can handle weight without excessive bending.

Cross-Sectional Shapes for Strength

Chapter 5 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

A commonly used section for a load-bearing bar provides a large load-bearing surface and enough depth to prevent bending.

Detailed Explanation

The shape of a beam's cross-section affects its strength and ability to resist bending. Engineers often choose shapes like I-beams because they effectively distribute the material, maximizing strength while minimizing weight. This optimization leads to cost-effective structures that are safe and efficient.

Examples & Analogies

Think about a ladder. A ladder with wide, flat rungs distributes weight better and feels sturdier than one with narrow, round rungs. Similarly, beams with optimized cross-sectional shapes are designed to handle loads more effectively.

Importance of Material Properties in Construction

Chapter 6 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The precise design of a bridge or a building has to take into account the conditions under which it will function, the cost and long period, reliability of usable material, etc.

Detailed Explanation

Materials used in construction must be durable and reliable over time. Factors such as load capacity, elasticity, and environmental conditions all affect material selection. Engineers must balance these requirements with cost efficiency to ensure constructions are safe and sustainable.

Examples & Analogies

When choosing materials for a home, you wouldn't use cardboard in place of wood or brick because it wouldn't be sturdy or long-lasting. In building design, engineers make similar choices, ensuring that materials used can withstand environmental stress over the years.

Key Concepts

-

Stress: The restoring force per unit area applied to materials.

-

Strain: The deformation experienced by materials in response to applied stress.

-

Elastic Limit: The maximum stress a material can withstand without permanent deformation.

Examples & Applications

A steel beam in a bridge uses its elastic properties to support large loads without bending excessively.

Cranes utilize thick metal ropes to safely lift heavy loads, relying on elastic behavior to prevent permanent deformation.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In bridges strong and towers tall, elastic properties will not let them fall.

Stories

Once upon a time, a crane lifted a heavy load with a rope so tight, it remembered to stay within its limits to prevent a fright!

Memory Tools

R.E.A.L. - Remember Elasticity Affects Load stability.

Acronyms

E.L.I.T.E. - Elastic Limit Is The Everything!

Flash Cards

Glossary

- Elasticity

The ability of a material to return to its original shape after deformation.

- Young's Modulus

A measure of the stiffness of a solid material, defined as the ratio of stress to strain.

- Yield Strength

The maximum stress that a material can withstand while still maintaining its elastic behavior.

Reference links

Supplementary resources to enhance your learning experience.