Productivity of Shovel

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Impact of Truck Placement

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we’ll explore how the placement of the truck affects the productivity of a shovel. Can anyone tell me what happens if a truck is placed too far from the excavator?

The cycle time would increase, which means it takes longer to dig and dump material.

Exactly! A greater distance leads to a larger swing angle, which directly correlates with increased cycle times. A reminder here is ‘Closer is Better’ – meaning the truck should ideally be placed at a 90-degree angle to minimize the swing angle.

So, what’s the ideal angle then?

The ideal angle of swing is 90 degrees, which promotes optimal productivity. How do we manage truck placement in real-life scenarios?

By ensuring there's clearance for the tail swing?

Absolutely! This brings us to the concept of truck spotting clearance. Always ensure there’s enough space for the shovel’s tail. Any questions so far?

Could you summarize that part again?

Sure! Proper truck placement minimizes swing angles, thereby reducing cycle times and maximizing productivity. Remember, proximity and angle are crucial!

Understanding Swing Angles

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s dive deeper into swing angles. What happens when the angle exceeds 90 degrees?

The productivity goes down because the shovel takes longer to swing.

Correct! A high swing angle increases cycle time. We can think of it as a seesaw effect where each degree of increase adds time and decreases efficiency. Can anybody remind me how to calculate cycle time?

Isn’t it based on the angle of swing and the actual height of cut?

Exactly! The angle of swing is pivotal. Now, what if I have an angle that's less than 90 degrees?

Then the productivity increases because the swing is faster.

Great! Ideal conditions dictate maintaining a 90-degree swing angle whenever possible to maximize efficiency.

Height of Cut and Correction Factors

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s focus on the height of cut. Why is it significant for shovel productivity?

Because it determines how effectively the shovel can dig into the material.

Exactly! If the actual height of cut matches the optimum height, we can achieve 100% productivity. How do we mathematically represent that?

We use the formula: actual height of cut divided by optimum height of cut.

Correct! If the percentage comes out less than 100%, you need to apply a correction factor. Let’s say the actual height of cut is 60% of optimum. What do we expect?

We would have reduced productivity then.

Correct! The correction factor will help us adjust the estimated productivity. Remember the optimal height for various materials!

Final Considerations for Productivity

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

We've covered a lot on productivity. What are the key factors affecting the performance of shovels?

Truck placement, angle of swing, and height of cut.

Right! And make sure we do not forget about factors like haul unit exchange time and truck spotting clearance. How can balancing these factors improve efficiency?

By ensuring the excavators don't waste time waiting for trucks, we can speed up the entire process.

Perfect! Continuous balancing of machines and timing can drastically improve production rates. Any final questions?

Could we go over how to apply the correction factors one more time?

Sure! Remember to compare actual versus optimal heights, use the correction factor tables when necessary, and factor in swing angle. With practice, these concepts become very intuitive!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section emphasizes the importance of truck proximity to excavators, the angle of swing, and height of cut in determining shovel productivity. It introduces correction factors used to adjust productivity estimates based on variations in these parameters.

Detailed

Productivity of Shovel

This section delves into the productivity of shovels in excavation projects, focusing largely on the operational efficiencies dictated by equipment arrangement and materials handling.

Key Factors Influencing Productivity

- Truck Placement: It is preferable to position trucks close to the excavators, ideally at a 90-degree angle. This minimizes the swing angle of the shovel and helps maintain efficient cycle times.

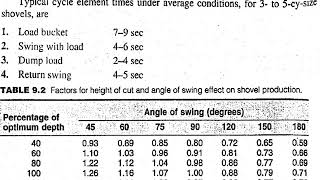

- Angle of Swing: The angle of swing, defined as the horizontal angle between the digging and dumping positions, significantly impacts cycle time and productivity. An increased angle typically leads to longer cycle times, which reduces productivity.

- Height of Cut: Productivity is ideally maximized when the actual height of cut equals the optimum height of cut for the material and equipment. If these heights differ, correction factors must be applied to estimate a more accurate productivity metric.

- Correction Factors: When the actual height of cut is less than or greater than the optimum, or if the swing angle deviates from 90 degrees, adjustments via correction factors become necessary. These factors are essential for estimating realistic productivity rates for shovels in varying project conditions.

Additional Considerations

- Truck Spotting Clearance: There should be enough clearance left for the tail swing of the shovel to avoid collisions when the truck is closely positioned.

- Haul Unit Exchange Time: The time taken for trucks to clear and be replaced can significantly affect the turnaround time and, consequently, productivity. Strategies should be in place to minimize this time.

Understanding these factors allows for precise estimation of shovel productivity, informing better project planning and execution.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Importance of Truck Placement

Chapter 1 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

They have poor mobility. So, that is why it is preferable to place a truck very close to the excavator. So, very commonly you can see that the truck is placed at 90 degree. So, the truck is placed at 90 degree, this will be 90 to the bucket position. So, this is a common position. So, basically angle of swing is nothing but the horizontal angle between the digging and the dumping position between the loading and the dumping position.

Detailed Explanation

When using an excavator, positioning the truck nearby is crucial due to poor mobility of the equipment. Ideally, the truck should be at a 90-degree angle to the excavator's bucket position, allowing for efficient loading. The angle of swing refers to the horizontal angle formed between where the digging occurs and where the material is dumped. Keeping the truck close reduces the time spent swinging the bucket, thereby increasing productivity.

Examples & Analogies

Imagine trying to hand someone a cup of water from across a long table versus passing it directly to them. The direct handoff (like keeping the truck close) is quicker and more efficient than stretching to reach it (like swinging the excavator's bucket further).

Impact of Angle of Swing

Chapter 2 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

As the truck moves further away, your angle of swing would increase. As the angle of swing increases, you can see that your cycle time will increase, the productivity will decrease.

Detailed Explanation

The angle of swing directly affects how long each cycle of loading takes. When the truck is positioned farther away, the excavator's bucket must swing a larger arc to reach the truck, leading to longer cycle times. Consequently, as cycle time increases, productivity decreases since less material is loaded in a given period.

Examples & Analogies

Consider a swing at a playground: the farther away you push off (the farther away the truck is), the longer it takes to come back to the starting point (loading). Keeping the swing close allows quicker and more efficient motions.

Optimal Conditions for Shovel Productivity

Chapter 3 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Ideal condition ideal production of shovel is based on 90 degrees swing that is what I told you, the truck will replace it 90 degree is ideal condition and the actual height of cut in your project site should be same as optimum height of cut.

Detailed Explanation

For shovels to operate at optimal productivity, the angle of swing should ideally be maintained at 90 degrees. Additionally, the actual height from which material is being cut should match the optimum height determined for the specific machine. This ensures that the machine operates at maximum efficiency, reducing the need for corrections that would otherwise lower productivity.

Examples & Analogies

Think of it like baking a cake: there’s a perfect temperature and time for baking (similar to the 90-degree angle and optimum height). Deviating from those can lead to a cake that's either undercooked or burned, just like suboptimal angles and heights affect the efficiency of the shovel.

Adjustment Factors for Productivity Estimation

Chapter 4 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now, let us see what are all the adjustment factors, we have to apply while doing the productivity estimation based upon the height of the cut of material actual height of cut of material in your project site and based upon the angle of swing that is going to depend upon the position of your truck relative to the position of your excavator.

Detailed Explanation

When estimating the productivity of a shovel, it's important to account for adjustment factors. These include the actual height of the cut compared to the optimum height, and the angle of swing created by the distance and position of the truck. If there’s a discrepancy between actual and optimal conditions, corrections must be applied to maintain realistic productivity estimates.

Examples & Analogies

Like adjusting a recipe depending on the ingredients you have (i.e., if you don’t have as much flour as needed, you adjust other ingredients). Similarly, if the height of cut differs from the optimum, adjustments in productivity estimations are essential.

Understanding Correction Factors

Chapter 5 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

If the actual height of cut is same as optimum height of cut, it means the percentage is 100% how do you calculate the percentage actual height of cut divided by optimum height of cut for the particular machine.

Detailed Explanation

A correction factor is applied when actual conditions deviate from ideal ones. If the actual height of cut equals the optimum height, the productivity percentage is 100%. This is calculated by dividing the actual height by the optimum height. If the height is less or more than optimum, a corresponding correction factor must be applied, as this will impact productivity significantly.

Examples & Analogies

Think of it like a score on a test. If you get everything right (100%), you don’t need any extra points (corrections). But if you miss some questions, you adjust your expectations based on how many you got right versus what was possible.

Importance of Truck Spotting Clearance

Chapter 6 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Another thing to be noted is truck spotting clearance. That means, as I told you, it is preferable to place a truck closer to the excavator. But at the same time, note that there should be some space left for the tail swing of the shovel.

Detailed Explanation

While it's beneficial for productivity to place the truck near the excavator, ensuring there's enough space for the excavator's tail swing is crucial. This prevents any accidental collisions and allows for full movement of the machinery without obstruction, which is crucial for maintaining efficiency on the site.

Examples & Analogies

Imagine driving a large truck in a tight garage. You want to park as close to the door as possible, but if there’s no clearance to open the door without hitting the wall, it creates a problem. Similar clearance for the excavator ensures smooth operations without interruptions.

Haul Unit Exchange Time

Chapter 7 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Other important factor is haul unit exchange time. That means the time needed for the loaded truck to leave its position. And for a new truck that is an empty truck to take the position.

Detailed Explanation

Haul unit exchange time plays a significant role in productivity, referring to the time needed for a truck that’s just been loaded to exit and for an empty truck to take its place. Effectively managing this exchange minimizes downtime, allowing for continuous loading and improving overall productivity on site.

Examples & Analogies

Think of it as a relay race; if the outgoing runner takes too long to pass the baton to the incoming runner, the team loses precious time. The quicker the transition between trucks, the more materials can be moved efficiently.

Estimating Shovel Productivity

Chapter 8 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Now let us see how to estimate the productivity of the shovel. So, for all these machines, the principle is going to be the same...

Detailed Explanation

Estimating shovel productivity involves calculating the volume that the bucket can carry, known as the heaped volume, and adjusting based on the bucket fill factor to account for material type. This value is then divided by the cycle time or adjusted by the number of cycles per hour to get the productivity rate. Further adjustments are needed based on conditions like swing angle and height of cut, ensuring accurate estimations.

Examples & Analogies

Consider it like managing a restaurant's output. You need to know how much each chef can cook per hour (capacity), how long each dish takes (cycle time), and adjust for busy days or special menus that may affect those times. Keeping track of this helps efficiently serve more customers.

Key Concepts

-

Truck Placement: Positioning trucks close to shovels minimizes swing angles and increases efficiency.

-

Swing Angle: The angle between the digging and dumping position that affects cycle time and productivity.

-

Height of Cut: The vertical distance of material that significantly influences shovel effectiveness.

-

Correction Factors: Adjustments applied based on actual vs. optimum cutting height and swing angle.

-

Truck Spotting Clearance: Required space to allow movement of the shovel without collisions during operation.

Examples & Applications

For maximum efficiency, position the truck at a 90-degree angle to the shovel to maintain ideal swing conditions.

If the actual height of cut is 4 meters and the optimum is 5 meters, the productivity will decrease by applying a correction factor.

Scheduling multiple trucks to optimize haul unit exchange time can reduce idle time for the shovel.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For shovel efficiency, stay close, not far; keep the angle at ninety, that’s the star!

Stories

Imagine a shovel working hard, lifting loads every minute near a truck standing guard. The truck is close, at ninety degrees, making the shovel's task as easy as a breeze!

Memory Tools

Remember 'ACTS': Angle, Cut Height, Trucks, and Swing for maximizing shovel power.

Acronyms

C.E.P.T. for clear factors

Clearance

Exchange Time

Placement

and Type of Cut.

Flash Cards

Glossary

- Angle of Swing

The horizontal angle between the digging and dumping position of a shovel.

- Cycle Time

The total time taken for the shovel to complete one full digging and dumping cycle.

- Correction Factor

A numerical adjustment applied to productivity estimates based on deviations from optimum operating conditions.

- Height of Cut

The vertical measurement of the material the shovel needs to excavate, crucial for determining productivity.

- Productivity

A measure of how efficiently a machine performs work, often represented as output per unit of time.

- Truck Spotting Clearance

The space required for the shovel's tail to swing without colliding into the parked truck.

Reference links

Supplementary resources to enhance your learning experience.