Analog-to-Digital Conversion (ADC)

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to ADC

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we're going to explore Analog-to-Digital Conversion, or ADC. How many of you know what ADC is?

Isn't it the way microcontrollers read analog signals from sensors?

Exactly! ADC allows microcontrollers to convert analog voltages from sensors into digital values. This makes it possible for the microcontroller to process and make decisions based on the data. Can anyone name a physical quantity that an analog sensor might measure?

Temperature! Like from an LM35 sensor.

Great example! The LM35 is an analog temperature sensor. Now, why do you think it's important for ADC to convert this analog signal into digital?

So that the microcontroller can understand and process it?

Exactly right! Remember, ADC bridges the gap between our physical world and digital processing in microcontrollers.

Resolution in ADC

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

So, let's dive deeper into a crucial aspect: Resolution. What do you think resolution means in the context of ADC?

I think it's about how precise the measurement can be.

Absolutely! ADC resolution refers to the smallest change in voltage that can be detected. For instance, an 8-bit ADC can represent 256 levels, while a 10-bit can represent 1024 levels. Student_1, can you guess which one offers more precise readings?

The 10-bit ADC! It has more levels to represent changes.

Right! Higher resolution means more accuracy. This leads us to consider how resolution impacts our projects, especially in applications needing precise sensor readings.

Sampling Rate and Its Importance

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's talk about Sampling Rate. Why might we need a high sampling rate for certain sensors?

If a sensor's output changes quickly, we need to sample it faster to capture all the changes.

Exactly! If a signal fluctuates rapidly and we have a low sampling rate, we might miss critical data points. For example, what could happen in a motion sensing application?

We could miss detecting when something moves or changes its state!

Well said! It's vital for capturing dynamic events accurately.

Application of ADC in Embedded Systems

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let's connect what we've learned about ADC to real-world applications. Can anyone think of a situation where ADC plays a critical role?

In robotics! They use sensors to navigate and control movement.

Exactly! ADC helps robots interpret sensor data to make decisions. Similarly, in IoT devices, accurate ADC conversion can significantly impact performance, especially in monitoring environmental conditions like temperature and humidity.

So, without ADC, our devices wouldn't understand the world around them?

You've got it! ADC is the gateway for microcontrollers to interact with the analog world.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section covers the fundamentals of ADCs in microcontrollers, including resolution and sampling rate, which are vital for interpreting analog signals from sensors effectively. It emphasizes the importance of ADCs in various applications within embedded systems and IoT devices.

Detailed

Analog-to-Digital Conversion (ADC)

Analog-to-Digital Conversion (ADC) is a crucial process that allows microcontrollers to interpret analog signals from sensors. ADCs internally digitize continuous voltage levels into discrete values, facilitating the processing of sensor data in a form that microcontrollers can use. The primary aspects of ADC include:

- Resolution: This defines the precision of the digital representation of the analog signal, typically measured in bits. For example, an 8-bit ADC offers 256 distinct values, whereas a 10-bit ADC can render up to 1024 unique values. Higher resolution means finer distinctions between different levels of input signals.

- Sampling Rate: This is the frequency at which an ADC samples an analog input. For dynamic signals, a higher sampling rate is essential to capture rapid changes effectively. Analog signals that vary quickly require faster sampling to provide an accurate digital representation, ensuring that no crucial data is lost.

ADCs are implemented in various microcontroller architectures, including AVR, PIC, and ARM Cortex devices, enabling diverse applications from simple reading tasks to complex control systems in embedded systems and IoT environments.

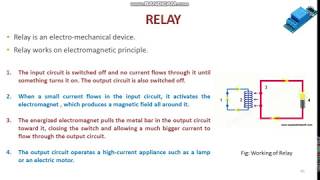

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to ADC

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Many microcontrollers, such as AVR, PIC, and ARM Cortex based devices, have built-in Analog-to-Digital Converters (ADCs) that allow them to read analog signals from sensors. ADCs convert the analog voltage from the sensor into a digital value that the microcontroller can process.

Detailed Explanation

Analog-to-Digital Converters (ADCs) are essential components in microcontrollers that enable the reading of analog signals. An analog signal is continuous and can take any value within a range (like temperature or light intensity), while a digital signal has discrete values (0s and 1s). The main job of an ADC is to convert these continuous analog voltages into precise digital values that a microcontroller can understand and manipulate. For example, when a temperature sensor outputs a varying voltage based on the temperature, the ADC takes this voltage and translates it into a corresponding digital number.

Examples & Analogies

Think of the ADC as a translator between two languages: the analog 'language' that sensors use to communicate information and the digital 'language' that microcontrollers understand. Just as a translator converts phrases from one language to another, an ADC converts the continuous signals into a format that the microcontroller can interpret.

ADC Resolution

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Resolution: ADC resolution defines the precision of the conversion, typically measured in bits. For example, an 8-bit ADC provides 256 possible values (0-255), while a 10-bit ADC provides 1024 possible values (0-1023).

Detailed Explanation

The resolution of an ADC refers to how many distinct values it can output for a given range of analog input. It is typically measured in bits. An 8-bit ADC means it can represent 2^8, which is 256 different values, ranging from 0 to 255. Conversely, a 10-bit ADC can represent 2^10, totaling 1024 possible values from 0 to 1023. Higher resolution means finer detail in the analog measurement. For example, if you are measuring a temperature range of 0-100 degrees Celsius, a 10-bit ADC would allow for slightly more accuracy compared to an 8-bit ADC.

Examples & Analogies

Imagine you are trying to measure the amount of sugar in a jar. If you have an 8-part scale, you can distinguish between only 256 levels of sugar. But if you upgrade to a 10-part scale, you can count 1024 different levels. The more levels you have, the more accurately you can determine just how much sugar is in the jar.

Sampling Rate

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Sampling Rate: The rate at which the ADC samples the analog input. Higher sampling rates are required for fast-changing signals, such as those from sensors in motion or temperature sensors.

Detailed Explanation

The sampling rate of an ADC is the number of times it takes a reading from an analog signal per second. This rate is crucial for accurately capturing the behavior of signals that change rapidly. For example, if a temperature changes quickly, a higher sampling rate means the ADC can provide more up-to-date readings and not miss any important changes. In applications where the signal is stable, a lower sampling rate may suffice.

Examples & Analogies

Consider a photographer trying to capture a fast-moving object. If they take a picture once every second, they may miss the action. However, if they take multiple pictures per second, they can capture the object in motion perfectly. Similarly, a high sampling rate helps ensure that the ADC captures every change in the analog signal.

Key Concepts

-

ADC: The process of converting analog signals to digital format.

-

Resolution: Indicating the precision of the converted digital value.

-

Sampling Rate: Refers to how frequently the analog signal is sampled.

Examples & Applications

Using an LM35 temperature sensor to measure room temperature and converting the output into a digital value using an ADC.

In robotics, sensors provide signals that need to be digitized using ADCs for processing by microcontrollers to steer motors.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

ADC helps us see, from analog to digital we plea!

Stories

Imagine a robot trying to feel temperature. Without ADC, it can’t understand the 'feel' of heat!

Memory Tools

A – Analog, D – Digital, C – Change: ADC indicates the change from analog to digital.

Acronyms

RSD

Resolution

Sampling rate

Digital output – the trio you need to remember for ADC.

Flash Cards

Glossary

- ADC

Analog-to-Digital Converter; a device that converts an analog voltage into a digital value.

- Resolution

The smallest change in input that can be detected by an ADC, usually measured in bits.

- Sampling Rate

The frequency at which an ADC takes samples of an analog signal, affecting the accuracy of the conversion.

Reference links

Supplementary resources to enhance your learning experience.