Summary of Key Concepts

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Sensors

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we’ll start with the basics of sensors. Can anyone tell me what a sensor does in an embedded system?

It measures physical quantities, like temperature or light.

Exactly! Sensors convert physical quantities into electrical signals. They can be either analog or digital. Can anyone explain the difference?

Analog sensors give continuous signals, and digital sensors provide discrete values.

Great job! Remember, analog sensors may require ADC to work with microcontrollers. This leads us to understand how ADC works. What do you think is the significance of resolution in ADC?

It defines how many levels of precision the ADC can provide.

Correct! Higher resolution means more accurate readings. Now let's summarize: sensors are vital components, and understanding their types helps us select the right one for our projects.

Actuator Control Basics

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Moving on to actuators, can anyone tell me what an actuator does?

Actuators perform actions based on signals from microcontrollers, like moving a motor.

Exactly! Actuators can be motors, servos, or relays, among others. What control techniques do we use for actuators?

We can control motors using PWM for speed and direction.

Correct! PWM allows us to adjust the speed of a motor by varying the duty cycle. Can anyone explain what an H-Bridge circuit does?

It allows the motor to change direction by controlling the voltage flow.

Right! Summarizing today, actuators perform tasks based on microcontroller commands, and control methods like PWM are crucial for effective operation.

Practical Applications of Sensors and Actuators

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s connect today’s learning to real-world applications. Can anyone give an example where both sensors and actuators are used together?

In temperature control systems! A temperature sensor can monitor the temperature and a fan actuator can adjust temperatures.

Exactly! This feedback control mechanism is essential for automating heating or cooling systems. What challenges might arise in these applications?

There could be issues with power consumption or signal noise.

Good point! Challenges like signal conditioning and power management are crucial in developing reliable embedded systems. Let’s recap: practical applications of sensors and actuators include various automated systems, and understanding the challenges helps ensure their effectiveness.

Challenges in Sensor and Actuator Interfacing

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

As we delve deeper, what challenges can we expect when interfacing sensors and actuators?

Signal conditioning is one challenge—we need to ensure signals are in the right format.

Exactly! Signal conditioning helps us get cleaner signals for accurate readings. What else?

Power consumption is another—especially in portable devices.

Right on target! Power optimization techniques are essential. Lastly, how can we handle noise interference?

Using shielding and software filters can help minimize noise.

Great insights! To sum up, challenges like signal conditioning, power consumption, and noise management are critical for successful sensor and actuator interfacing.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section outlines important concepts in sensor interfacing, including the types of sensors and actuators, control techniques, and common practical applications. It also addresses challenges encountered during interfacing, providing a comprehensive summary of key information for effective implementation in embedded systems.

Detailed

Summary of Key Concepts

In this section, we explore the fundamental aspects of interfacing sensors and actuators with microcontrollers, which are essential in embedded systems and IoT devices. Sensors are categorized based on their signal types into analog and digital, with analog sensors requiring Analog-to-Digital Conversion (ADC) for signal processing. Actuators, like motors and relays, perform physical actions based on signals from microcontrollers, often utilizing techniques such as Pulse Width Modulation (PWM) for control. Practical applications such as temperature control systems exemplify how sensors and actuators interact to create automated responses. Furthermore, common challenges in this field include signal conditioning, power consumption considerations, and the management of noise interference. Understanding these concepts is crucial for designing effective and efficient embedded systems.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Sensor Interfacing

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Sensors convert physical quantities into electrical signals that microcontrollers can read. These signals can be either analog (requiring ADC conversion) or digital.

Detailed Explanation

Sensor interfacing involves connecting sensors to a microcontroller to capture real-world data. Sensors measure physical quantities like temperature or light and convert those measurements into electrical signals. There are two main types of signals: analog and digital. Analog signals are continuous and vary in voltage, while digital signals are discrete and represent data in binary form (0s and 1s). When using analog sensors, the microcontroller needs to convert these signals using an Analog-to-Digital Converter (ADC) so it can process the data.

Examples & Analogies

Think of a digital thermometer that gives you temperature readings. The sensor inside it measures the temperature as a continuous value (analog), and the thermometer converts this reading into a digital display (digital) that you can easily read.

Actuator Control

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

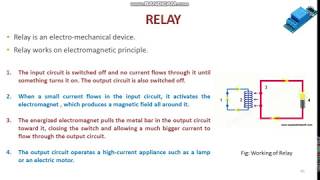

Actuators perform actions like moving a motor or switching a relay. Actuator control often involves techniques like PWM for speed control or H-Bridge circuits for motor direction control.

Detailed Explanation

Actuators are devices that perform actions based on instructions from the microcontroller. For example, when the microcontroller determines that a fan needs to be turned on, it sends a signal to the actuator to start the motor. Methods used for controlling motors include Pulse Width Modulation (PWM), which adjusts the speed of the motor by changing the duration of the signal sent. An H-Bridge circuit can control the direction of current flow in a motor, allowing it to spin forwards or backwards.

Examples & Analogies

Consider a remote-controlled car. The remote sends signals to the car's microcontroller, telling it to move forward or backward. The microcontroller uses actuators to control the car's motors, applying PWM to adjust the speed like how you may press a car's accelerator pedal lightly for slow movement or fully for a fast drive.

Practical Applications

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Embedded systems often use both sensors and actuators to achieve feedback control in applications like temperature control systems, robotics, and automation.

Detailed Explanation

In embedded systems, sensors and actuators work together to manage tasks autonomously. For example, in a smart thermostat, a temperature sensor continuously reads the room temperature (input). Based on this information, the microcontroller decides whether to turn the heating or cooling systems on or off (output through actuators). This loop of sensing and acting is an example of feedback control, wherein the system adjusts its operations based on the sensor data.

Examples & Analogies

Let's imagine a home heating system. A thermostat (sensor) detects when the room temperature drops below a set point. It then signals the heater (actuator) to turn on until the desired temperature is reached. Once it does, the thermostat turns off the heater. This interaction between sensor and actuator ensures that the home remains comfortably warm without constant human intervention.

Challenges in Interfacing

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Signal conditioning, power consumption, and noise interference are common challenges that must be addressed in sensor and actuator interfacing.

Detailed Explanation

When interfacing sensors and actuators, there can be challenges that need attention. Signal conditioning adjusts the signals from sensors so they can be accurately read by the microcontroller. Managing power consumption is critical, especially in battery-powered devices, where every bit of power saves battery life. Additionally, noise interference can distort sensor readings, making it essential to use techniques like shielding wires and incorporating filters to ensure clear signal transmission.

Examples & Analogies

Imagine a musician trying to read sheet music while in a noisy café. The loud voices and clattering dishes are like interference in electrical signals. Just like the musician might need to move to a quieter spot to play correctly, engineers must ensure that sensors are shielded from noise to function properly. Moreover, using power-efficient devices is like using rechargeable batteries to keep the musician playing longer without needing to replace batteries frequently.

Key Concepts

-

Sensor Interfacing: Converting physical quantities into electrical signals.

-

Actuator Control: Performing actions based on microcontroller signals.

-

Analog and Digital Signals: The two types of sensor outputs.

-

ADC: Important for transforming analog signals into a usable digital format.

-

PWM: Key for controlling motor speeds and directions.

-

Challenges: Signal conditioning, power consumption, and noise management.

Examples & Applications

Using an LM35 temperature sensor to monitor room temperature.

Controlling a DC motor using PWM to adjust speed in a robotics project.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Sensors sense, with signals align, turning data to numbers, every time.

Stories

Imagine a room where the temperature is high. A sensor detects it, and a fan starts to fly, cooling the space, as it works with grace, thanks to their teamwork, the heat's out of place.

Memory Tools

S.A.P—Sensors for sensing, Actuators for action, PWM for power control. Remember SAP!

Acronyms

SENS—Sensing Environmental Needs with Sensors.

Flash Cards

Glossary

- Sensor

A device that converts physical quantities into electrical signals.

- Actuator

A device that performs a physical action (e.g., turning, moving) based on signals.

- ADC (AnalogtoDigital Converter)

A component that converts an analog signal to a digital signal that the microcontroller can process.

- PWM (Pulse Width Modulation)

A method used to control the power supplied to electrical devices, particularly for identifying speeds in motors.

- HBridge

A circuit that allows a voltage to be applied across a load in either direction.

- Signal Conditioning

The process of manipulating a signal to meet the requirements for further processing.

Reference links

Supplementary resources to enhance your learning experience.