Capacity 20 kN to 200 kN

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Compaction Equipment

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're going to talk about field compaction equipment, particularly those that have capacities between 20 kN and 200 kN. Can anyone tell me what compaction means?

Does it mean compressing soil or aggregate to increase its density?

Exactly! Compaction is essential in construction to ensure stability. We have several types of equipment like Smooth Wheeled Steel Drum Rollers, Pneumatic Tyred Rollers, and Sheepsfoot Rollers. Let's start with the smooth wheeled steel drum rollers.

What are the specific capacities of these rollers?

Great question! These rollers have a capacity ranging from 20 kN to 200 kN. Now, when would we use these rollers?

Are they good for all types of soil?

Not exactly! They are suitable for well-graded sand, gravel, and low plasticity silt, but not for uniform sand or soft clay. Remember the acronym 'WELL' for the suitable types: Well-graded, Efficient, Low plasticity. Let's move on.

Pneumatic Tyred Rollers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's discuss pneumatic tyred rollers. Who can describe their features?

They usually have two axles with rubber tires, right?

Correct! These rollers often add dead weight, like water, to achieve a weight of 100 to 400 kN. What kinds of soil are they suitable for?

They work for most coarse and fine soils, but not soft clay.

Nice recall! Remember the mnemonic 'PNEUMATIC': Perform Neatly, Ensure Uniform Maintenance And Treat Inconsistent Clay. This will help you remember what they're best at.

What happens if we use them on very soft clay?

That's a good question! Using them on very soft clay can lead to ineffective compaction. Let's now cover Sheepsfoot rollers.

Sheepsfoot Rollers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Sheepsfoot rollers have a drum fitted with club-shaped feet which provide a kneading action. Can anyone explain why this design is beneficial?

It helps compact fine-grained soil better?

Exactly! They are great for fine-grained soil, sand, and gravel with fines, with a weight between 50 to 80 kN. Remember this: 'SHEEP' means Strong, Heavy, Effective for Extra Proctor. Can you recall what Proctor means?

Proctor refers to the density of soil?

Right! It's crucial for understanding how well soil can be compacted. Lastly, why do you think different types of rollers are important?

So we can choose the right one based on soil conditions!

Exactly! Understanding the equipment allows for better construction outcomes.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section discusses various types of field compaction equipment, specifically focusing on Smooth Wheeled Steel Drum Rollers, Pneumatic Tyred Rollers, and Sheepsfoot Rollers. It highlights their capacities, suitable soil types, and limitations.

Detailed

Detailed Summary

This section covers the different types of field compaction equipment, detailing their capacities between 20 kN to 200 kN. Classifications include:

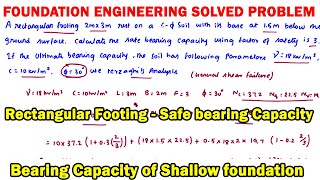

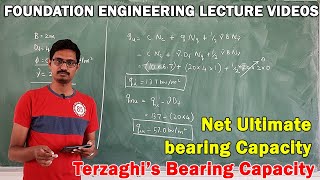

- Smooth Wheeled Steel Drum Rollers: These machines range from 20 kN to 200 kN, are either self-propelled or towed, and are well-suited for compaction of well-graded sand, gravel, and low plasticity silt. However, they do not perform well on uniform sand, silty sand, and soft clay.

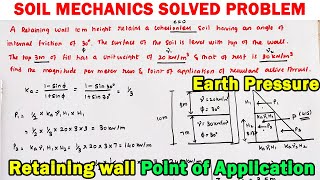

- Pneumatic Tyred Rollers: Typically having two axles with rubber tires, these rollers combine dead weight, ranging from 100 kN to 400 kN. They are effective for most coarse and fine soils but struggle with very soft clay and highly variable soil types.

- Sheepsfoot Rollers: These can also be self-propelled or towed and have a unique drum design with projecting club-shaped feet for a kneading action. Weighing between 50 kN to 80 kN, these rollers are optimal for fine-grained soil, sand, and gravel with significant fines.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Smooth Wheeled Steel Drum Rollers

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Capacity 20 kN to 200 kN

- Self propelled or towed

- Suitable for well graded sand, gravel, silt of low plasticity

- Unsuitable for uniform sand, silty sand and soft clay

Detailed Explanation

Smooth wheeled steel drum rollers are compacting machines that come with a capacity ranging from 20 kN to 200 kN. This means they can exert a weight that falls within this range, making them effective for various soil types. These machines can be either self-propelled, meaning they can move by themselves, or towed by another vehicle.

They are particularly effective on well-graded sand, gravel, and silt with low plasticity, which refers to how easily the soil can be molded. However, they should not be used on certain types of soil, such as uniform sand, silty sand, and soft clay, as these materials do not compact well with this type of roller.

Examples & Analogies

Imagine trying to flatten a soft dough with a rolling pin. If the dough is too soft or sticky, the rolling pin won't work effectively. Similarly, smooth wheeled steel drum rollers are like the rolling pin for certain soils—they work best on materials that can hold their shape while being compressed.

Soil Types and Compatibility

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Suitable for well graded sand, gravel, silt of low plasticity

- Unsuitable for uniform sand, silty sand and soft clay

Detailed Explanation

Understanding which soils are compatible with smooth wheeled steel drum rollers is crucial for effective compaction. The term 'well-graded' refers to soil that has a variety of particle sizes, which allows for better packing and compaction. Gravel and silt with low plasticity are great examples of suitable materials.

On the other hand, uniform sand, silty sand, and soft clay have consistency issues that make it difficult for these rollers to compact them effectively. This means if they are used on these types of soil, the desired level of compaction may not be achieved, leading to weak foundations or road surfaces.

Examples & Analogies

Think of packing a suitcase. It's easier to fit a mix of small and large items than to fit a lot of items that are all the same size and shape. Similarly, well-graded soil packs more tightly than uniform soil, allowing for better compaction with rollers.

Key Concepts

-

Smooth Wheeled Steel Drum Rollers: Utilized for well-graded sand, gravel, and low plasticity silt.

-

Pneumatic Tyred Rollers: Effective for most coarse and fine soils but not soft clay.

-

Sheepsfoot Rollers: Ideal for fine-grained soil, sand, and gravel with significant fines.

Examples & Applications

A construction project using smooth wheeled rollers on a gravel base to ensure a solid foundation.

Pneumatic tyred rollers being utilized on a mixed sandy soil to enhance compaction efficiency.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

If soil compaction's what you seek, smooth drum rollers can’t be weak. For even ground, use the 'SHEEP,' kneading as they compact and reap.

Stories

Imagine a construction site where smooth wheeled rollers glide effortlessly over well-graded gravel, compacting it soundly. Nearby, pneumatic rollers add weight, while sheepsfoot rollers dance over fine sand, their club-shaped feet mixing and flattening like chefs perfecting dough.

Memory Tools

To remember suitable soils, think 'WELL': Well-graded, Efficient, Low plasticity for smooth rollers.

Acronyms

Remember 'SHEEP' for Sheepsfoot Rollers

Strong

Heavy

Effective for Extra Proctor.

Flash Cards

Glossary

- Compaction

The process of increasing the density of soil or aggregate by reducing air voids.

- Smooth Wheeled Steel Drum Rollers

A type of roller with smooth steel drums used mainly for packing well-graded soils.

- Pneumatic Tyred Rollers

Rollers with rubber tires which help in compacting various soil types through their dead weight.

- Sheepsfoot Rollers

Rollers featuring club-shaped feet designed to knead and compact fine-grained soils.

- Wellgraded soil

Soil with good particle size distribution, allowing for greater density upon compaction.

- Plasticity

The property of soil that allows it to deform and flow without cracking.

Reference links

Supplementary resources to enhance your learning experience.