Pneumatic Tyred Rollers - 1.2

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Understanding Pneumatic Tyred Rollers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will explore pneumatic tyred rollers. These machines have two axles with rubber tyres that allow them to operate effectively over the full width of a track. Why do you think their design is an advantage, Student_1?

I think it helps in covering more area without needing multiple passes.

Exactly! This design enhances efficiency. They can weigh anywhere from 100 to 400 kN when fully loaded. Student_2, why would adding dead weight, like water, be beneficial?

I assume it increases the compactive effort on the soil.

Correct! Heavier weight allows for deeper soil penetration during the compaction process. But these rollers have limitations too. Can anyone tell me what type of soils they are not suited for?

Very soft clay and highly variable soils.

Great! To remember the types of soils to avoid, how about the mnemonic GHS, which stands for Gravy, Honey, and Soupy, indicating too soft or inconsistent soils? Any questions before we summarize?

No questions, I think I understand it well now.

Perfect! To recap, pneumatic tyred rollers enhance efficiency, operate effectively due to their weight, and are suitable for various soils but should not be used on soft clay or highly variable soils.

Applications of Pneumatic Tyred Rollers in the Field

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s talk about practical applications. Where do you think pneumatic tyred rollers are most commonly used, Student_1?

I think they would be used in road construction.

That's right! They are often used in roadwork, where compaction of various soil types is necessary. Student_2, can you think of a scenario where their use would be detrimental?

In a situation with very soft ground, they might not provide effective compaction.

Exactly! In such cases, a sheepsfoot roller or vibratory roller may be a better choice. Remember, choosing the right compaction equipment depends on the soil type. Any thoughts, Student_3?

It seems like understanding the soil composition is really important for effective compaction.

Absolutely! To summarize, pneumatic tyred rollers are effective in road construction but should be avoided on soft soils. Always consider soil properties before choosing your equipment.

Limitations and Considerations

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s now explore the limitations of pneumatic tyred rollers. What factors can influence their effectiveness, Student_4?

I believe the moisture content in the soil could affect their performance.

You've hit the nail on the head! Caution must be exercised during wet conditions. Student_1, why do you think variability in soil composition can be a challenge for these rollers?

Because the pressure distribution from the tyres might not penetrate through inconsistent layers effectively.

Exactly! The pressure needs to be balanced. It's essential to assess the soil composition beforehand. Let's strengthen our understanding with some scenarios: If you encounter muddy terrain, what would you recommend?

Switching to a different type of roller, perhaps a vibratory or sheepsfoot roller.

Correct! In summary, always evaluate soil conditions and avoid using pneumatic tyred rollers on soft or variable terrains.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

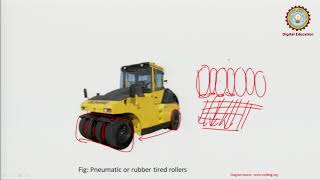

Pneumatic tyred rollers are typically equipped with two axles carrying rubber tyred wheels, allowing them to cover the full width of a track. Their weight, enhanced with added dead load, ranges from 100 to 400 kN and they are suited for most coarse and fine soils, although they are unsuitable for very soft clay and highly variable soils.

Detailed

Pneumatic Tyred Rollers

Pneumatic tyred rollers are critical in the compaction process, characterized by their unique structure that features two axles equipped with rubber tyred wheels. This design facilitates coverage across the entire width of the track, optimizing the compaction efficiency. The weight of these rollers can be increased with the addition of a dead load, typically consisting of water, raising their total weight between 100 kN and 400 kN.

These rollers are versatile, capable of effectively compacting a wide range of soil types, particularly suitable for most coarse and fine soils. However, they are not recommended for use on very soft clay or highly variable soil conditions as their performance can significantly deteriorate under these circumstances. Understanding the applications and limitations of pneumatic tyred rollers enhances the effectiveness of soil compaction strategies in various construction and civil engineering projects.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Overview of Pneumatic Tyred Rollers

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Usually two axles carrying rubber tyred wheels for full width of track.

Detailed Explanation

A pneumatic tyred roller is a type of compaction equipment designed for earthwork tasks. Typically, it has two axles, and each axle is equipped with rubber-tyred wheels. This design allows the roller to cover the full width of a track, providing an effective compaction solution across the entire area being worked on. The use of rubber tires helps in adapting to different soil types and conditions.

Examples & Analogies

Think of a pneumatic tyred roller like a large flatbed truck with heavy, soft tires. Just as the truck can drive smoothly over various terrains and not damage the underlying surface, the rubber tyres of the roller help it compact the ground without excessively digging into it. This is similar to how a heavy vehicle, when driven over soft mud, can flatten the surface without getting stuck.

Dead Load and Weight Adjustment

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Dead load (water) is added to give a weight of 100 to 400 kN.

Detailed Explanation

Pneumatic tyred rollers can enhance their effectiveness by adding a dead load, which is typically achieved by filling the tires with water. This additional weight, which can range from 100 to 400 kN, increases the compactive effort of the roller. The added weight improves the machine's ability to compact the soil more thoroughly, especially in coarser or fine-textured soils.

Examples & Analogies

Imagine trying to stamp down a patch of soil with just your foot. Now, think about putting on a heavy boot. With the heavier boot, your foot can apply more pressure, making it easier to compact the soil. The dead load acts in a similar way for the pneumatic tyred roller, allowing it to compact the ground more effectively.

Suitability for Soil Types

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Suitable for most coarse & fine soils. Unsuitable for very soft clay and highly variable soil.

Detailed Explanation

Pneumatic tyred rollers are versatile and can effectively compact most coarse and fine soils, making them useful for a variety of construction and earthwork projects. However, they are not recommended for use on very soft clay or highly variable soils. In these cases, the soft clay may become too compacted or not compact well at all due to the rubber tires not being able to penetrate the ground effectively.

Examples & Analogies

Think of using a sponge to soak up different liquids. A sponge works great for water but fails miserably with thick syrup. Similarly, pneumatic tyred rollers work best on certain soil types, just like your sponge can effectively handle some substances while struggling with others.

Key Concepts

-

Pneumatic Tyred Rollers: Equipment designed for soil compaction using rubber tyres.

-

Dead Load: Weight added to a roller to enhance its compaction ability.

-

Soil Suitability: The effectiveness of rollers depending on soil type, especially coarse and fine soils.

Examples & Applications

A pneumatic tyred roller weighing 200 kN effectively compacts a newly laid asphalt road surface.

Using a pneumatic tyred roller in wet sandy soil can lead to ineffective compaction due to soil displacement.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Roller with rubber wheels, compacting with great zeal, on sturdy surfaces, their power is real.

Stories

Imagine a lively construction site where a pneumatic roller rolls over the terrain, thumping and reshaping the earth beneath its weight, but moving away when it encounters soft clay, knowing its limits instinctively.

Memory Tools

Remember 'SPS' - Suitable for most soils except soft clay: S for Suitable, P for Pneumatic rollers, and S for Soils!

Acronyms

P.T.R. (Pneumatic Tyred Roller) - Perfect Tool for Roads!

Flash Cards

Glossary

- Pneumatic Tyred Rollers

Compaction equipment with two axles carrying rubber tyred wheels, suitable for various soil types primarily coarse and fine.

- Compaction

The process of increasing soil density by reducing air voids, typically achieved through mechanical means.

- Dead Load

Additional weight, often water, added to a roller to increase its compactive force.

- Soil Composition

The mixture of different soil types, which can affect compaction effectiveness.

Reference links

Supplementary resources to enhance your learning experience.