Suitable for fine grained soil, sand & gravel with considerable fines.

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Smooth Wheeled Steel Drum Rollers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we start with the smooth wheeled steel drum rollers. Can anyone tell me what these rollers are used for?

They are used for compacting soil, right?

Exactly! These rollers are particularly effective for well-graded sand, gravel, and low plasticity silt. Their capacity ranges from 20 kN to 200 kN.

What about the soil types they are not suited for?

Great question, Student_2! They are unsuitable for uniform sand, silty sand, and soft clay. Remember it as 'US - Unfit Soil'.

So they can either be self-propelled or towed?

Correct! Being versatile is one of their strengths. Recap: Suitable for well-graded soils, not for uniform sand or soft clay. Any more questions?

Pneumatic Tyred Rollers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s move on to pneumatic tyred rollers. Who can explain their structure?

They have two axles with rubber tyres, don’t they?

Yes! They function well when added with dead load, commonly water, giving a total weight of 100 to 400 kN. Now, what types of soils are they suitable for?

Most coarse and fine soils?

Exactly! However, they are not effective on very soft clay or highly variable soils. Keep in mind this limitation. Remember, 'CLOSED, Can't Load 'Soft Clay'.

That’s helpful! So they enhance compaction effectively?

Indeed! Let’s summarize: Pneumatic rollers rely on tyre pressure and weight for effective compaction but have limits on soft or variable soils.

Sheepsfoot Rollers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let’s discuss sheepsfoot rollers. What do you know about them?

They knead the soil, right?

True! They have a drum with projecting club-shaped feet that apply kneading action. What’s their typical weight range?

Between 50 to 80 kN!

Right again! And what types of soils are they ideally suited for?

Fine-grained soil, sand, and gravel with fines.

Correct! Keep in mind that these rollers are versatile for fine soils. Summarize: Sheepsfoot rollers are effective for kneading fine-grained soils and gravel.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section discusses different compaction equipment, including smooth wheeled steel drum rollers, pneumatic tyred rollers, and sheepsfoot rollers, emphasizing their suitability for various soil types. Special focus is provided on the sheepsfoot roller, which is particularly effective for fine-grained soils and is designed for kneading action.

Detailed

Detailed Summary

This section of the chapter provides an overview of various types of compaction equipment that is particularly effective for fine-grained soils, sand, and gravel with considerable fines. Understanding these tools is essential for soil stabilization and construction processes.

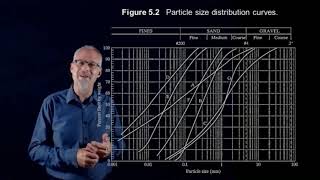

Types of Compaction Equipment:

- Smooth Wheeled Steel Drum Rollers:

- Capacity ranges from 20 kN to 200 kN.

- Can be self-propelled or towed and are ideal for well-graded sand, gravel, and silt of low plasticity.

- Not effective on uniform sand, silty sand, or soft clay, limiting their application.

- Pneumatic Tyred Rollers:

- These generally consist of two axles that carry rubber-tyred wheels, and operational weights are enhanced with additional dead load (water) of 100 to 400 kN.

- Suitable for most coarse and fine soils, but ineffective on very soft clay or highly variable soil types.

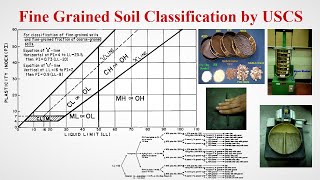

- Sheepsfoot Rollers:

- Available in self-propelled or towed variations, these rollers feature a drum equipped with club-shaped feet that knead the soil.

- Typically weigh between 50 to 80 kN and excel in compacting fine-grained soil, sand, and gravel while dealing with substantial fines.

Understanding the right equipment to use according to the soil type is crucial for achieving the desired compaction and stability in construction projects.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Sheepsfoot Roller Overview

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Self propelled or towed

- Drum fitted with projecting club shaped feet to provide kneading action.

- Weight of 50 to 80 kN

Detailed Explanation

The Sheepsfoot Roller is a type of compaction equipment used in construction. It can either move on its own (self-propelled) or be pulled behind a vehicle (towed). The roller has a drum that is designed with club-shaped feet, which help knead the soil during the compaction process. This kneading action effectively compresses the soil particles, making them more stable. The Sheepsfoot Roller typically weighs between 50 to 80 kilonewtons, which is essential for exerting enough pressure on the soil.

Examples & Analogies

Imagine stepping into a sandy beach with your bare feet. As you walk, your feet press down into the sand and compact it. The Sheepsfoot Roller works in a similar way; its weighted drum and projecting feet press down vigorously onto the soil, ensuring it is tightly compacted, just like your feet compact the sand under them.

Suitability for Soil Types

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Suitable for fine grained soil, sand & gravel with considerable fines.

Detailed Explanation

The Sheepsfoot Roller is particularly effective for compacting fine-grained soils, such as silts and clays, as well as sands and gravel that contain a significant amount of finer particles (referred to as 'considerable fines'). The design of the roller allows it to penetrate and knead these materials effectively, enhancing their density and strength, which is vital for construction applications such as road building and foundation preparation.

Examples & Analogies

Consider mixing dough for bread. When you knead the dough, you help the flour and water combine effectively, leading to a stronger and more cohesive mixture. Similarly, the Sheepsfoot Roller kneads and compresses the soil, ensuring that the grains of sand, silt, and clay bond well together to create a stable ground.

Key Concepts

-

Compaction Equipment: Includes various types to aid in soil stabilization and construction.

-

Smooth Wheeled Rollers: Effective for well-graded soils but not suitable for soft clays.

-

Pneumatic Rollers: Combine weight and tyre pressure for effective usage on various soils.

-

Sheepsfoot Rollers: Ideal for kneading fine-grained soils to aid compaction.

Examples & Applications

Using a smooth wheeled roller on a gravel construction site to ensure even compaction.

Employing sheepsfoot rollers on a clayey site to achieve suitable soil density.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

To knead the soil just right, sheepsfoot rollers show their might.

Stories

Imagine a builder with a toolbox; in it, a sheepsfoot roller kneads the finest sand and clay to ensure sturdy ground.

Memory Tools

To recall the types: 'SSP' - Smooth, Sheepsfoot, Pneumatic!

Acronyms

RAPID - Rollers Aid in Proper Intense Density compression.

Flash Cards

Glossary

- Smooth Wheeled Steel Drum Rollers

Compaction equipment powered by steel drums for flattening surfaces, effective for certain soil types.

- Pneumatic Tyred Rollers

Rollers that use rubber tyres to compact soil and typically require dead weight for effectiveness.

- Sheepsfoot Roller

A roller that features club-shaped feet designed to knead and compact fine-grained soils.

Reference links

Supplementary resources to enhance your learning experience.