Suitable for well graded sand, gravel, silt of low plasticity

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Smooth Wheeled Steel Drum Rollers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will start by discussing smooth wheeled steel drum rollers. They have capacities ranging from 20 kN to 200 kN. Can anyone tell me what types of soil they can effectively compact?

Are they good for well graded sand and gravel?

Exactly, Student_1! They are suitable for well graded sand, gravel, and silt of low plasticity. Remember the acronym WGS for Well Graded Soils!

What about uniform sand or soft clay?

Great question, Student_2. These rollers are actually unsuitable for uniform sand, silty sand, and soft clay. Why do you think that is?

Maybe because they can’t penetrate those types effectively?

Right! Their weight and action are not designed for penetrating softer soils. Let's remember, WGS for smooth wheel applications but not for soft soils!

What’s the main purpose of using these rollers?

The main purpose is to create a denser soil structure that is essential for construction stability. Nice engagement today! Recapping: Smooth wheeled steel drum rollers are WGS suitable, ineffective on soft soils.

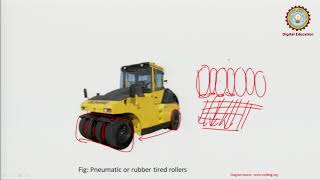

Pneumatic Tyred Rollers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, we move on to pneumatic tyred rollers. Can someone describe their common features?

They have two axles with rubber wheels, right?

Exactly! They usually have two axles and can carry weights up to 400 kN by adding water. What types of soils can they compact?

They can compact most coarse and fine soils.

Correct, Student_2! But they are ineffective on very soft clay. Remember, PWTS: Pneumatic for all soils excluding soft clay.

So, why do they need water?

Good question, Student_3. Water increases their dead load, allowing for better compaction. Heavy loads compress the soil better.

What would you recommend for soft clay, then?

In that case, sheepsfoot rollers would be a better option! Always consider soil properties before selecting equipment.

Sheepsfoot Rollers

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let's discuss sheepsfoot rollers. What do you know about how they operate?

They have drum fitted with feet that kneads the soil, right?

Exactly! This kneading action is excellent for compacting fine-grained soil. They typically weigh between 50 to 80 kN. What’s their suitability?

They work well with fine-grained soil and gravel with fines.

Yes! Remember FS for Fine Soils with Sheepsfoot rollers. However, they are also unsuited for certain soil types. Can anyone guess which?

Is it coarse gravel?

They might handle some coarse gravel, but they struggle with uniform sand and very coarse soils. Their kneading action supports heavy compaction effectively on fine materials.

So for varying soil textures, we need to carefully choose the compactor?

Precisely! Always assess the soil and compaction needs before selecting equipment. Well done today! Let's recap: Sheepsfoot rollers are FS suitable for fine materials but tricky with coarse.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section details several types of field compaction equipment, such as smooth wheeled steel drum rollers and pneumatic tyred rollers. It highlights the suitability of these machines for different soil types, especially for well-graded sand, gravel, and silt of low plasticity, while noting their unsuitability for certain soils too.

Detailed

In this section, we explore various types of compaction equipment used in field operations, focusing primarily on their application with well graded sand, gravel, and silt of low plasticity. The primary equipment types discussed include smooth wheeled steel drum rollers, pneumatic tyred rollers, and sheepsfoot rollers. Each type of roller has specific capacity ranges, functionalities, and is suitable for various soil types. For example, smooth wheeled steel drum rollers have a capacity ranging from 20 kN to 200 kN and are ideal for well graded soils, while pneumatic tyred rollers are versatile across coarse and fine soils but ineffective on very soft clay. Understanding the suitability and limitations of these compaction equipment types is crucial for selecting the right machinery in construction projects. This section highlights important concepts regarding soil mechanics and compaction methodologies.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Suitable Soil Types

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Suitable for well graded sand, gravel, silt of low plasticity

Detailed Explanation

This section describes the types of soil that are suitable for compaction using specific equipment, particularly focusing on well-graded sand, gravel, and silt that has low plasticity. Well-graded materials have a good range of particle sizes, which allows for better compaction and stability when building foundations or layers for roads.

Examples & Analogies

Imagine filling a container with different sized balls (like marbles, ping-pong balls, and tennis balls). When you fill the container with various sizes, they fit together tightly, much like well-graded sand and gravel. Now, picture trying to fill that same container with only one size of ball; there will be gaps, resulting in less stability. This is why well-graded materials are preferred for construction.

Characteristics of Soil Types

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Well graded sand, gravel, silt of low plasticity are known for their compaction efficiency and stability.

Detailed Explanation

The well-graded sand and gravel have the characteristic of being able to densify well when compacted. Low plasticity silt means that the material does not behave like clay, which can become very soft when wet. This stability is crucial for construction projects where strong, compacted layers are required to support structures.

Examples & Analogies

Think of baking a cake with different ingredients. If you use ingredients with the right texture and combination, the cake rises well and holds its shape. If you used something that is too soft or hasn’t been mixed properly, the cake would collapse. Similar principles apply to soil; well-graded types hold together better under weight.

Limitations of Other Soil Types

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Unsuitable for uniform sand, silty sand and soft clay.

Detailed Explanation

This part emphasizes the types of soil that are not suitable for efficient compaction with the described equipment. Uniform sand lacks the necessary variation in particle size, which leads to poor compaction. Silty sand can behave unpredictably based on moisture, and soft clay can become easily deformed under pressure, causing foundation instability.

Examples & Analogies

Imagine trying to build a sandcastle with only fine sand at the beach. It might look good initially, but as soon as you apply pressure or water to it, the structure collapses. Similarly, in construction, if we use soils that are unsuitable, our 'sandcastle'—like a building or road—might not stand strong.

Key Concepts

-

Smooth Wheeled Steel Drum Rollers: Suitable for well graded soils but not soft clays.

-

Pneumatic Tyred Rollers: Versatile for most soils but ineffective on very soft clays.

-

Sheepsfoot Rollers: Ideal for fine-grained soils due to kneading action.

Examples & Applications

Using a smooth wheeled steel drum roller on a gravel road to enhance stability.

Employing a sheepsfoot roller for compacting a clay-heavy embankment in highway construction.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

To compact right and make it tight, use the smooth wheels and soil feels right.

Stories

Imagine a construction site where smooth rollers dance over gravel, leaving no soft clay untouched—compact, dense, secure!

Memory Tools

Remember 'WGS' for smooth wheels - Well Graded Sands!

Acronyms

PWTS

Pneumatic Rollers for Most Types

but not Soft (clay)!

Flash Cards

Glossary

- Smooth Wheeled Steel Drum Rollers

Heavy machinery used for compacting soil, typically employed on well graded sands and gravels.

- Pneumatic Tyred Rollers

Compaction equipment with rubber tyres that provide flexibility and are suitable for most soil types.

- Sheepsfoot Rollers

Compaction device equipped with feet to knead the soil, best for fine-grained soils.

Reference links

Supplementary resources to enhance your learning experience.