Chemical Composition of Cement

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to OPC

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we will explore Ordinary Portland Cement, or OPC. Do any of you know why OPC is such a critical material in construction?

Is it because it holds the concrete together?

Exactly! It acts as the binder in concrete, which is essential for its strength and durability. Now, let's dive into how OPC is made.

How is it actually produced?

Good question! OPC is produced by heating a mixture of limestone and clay at high temperatures, around 1450°C, which results in clinker. This clinker is then ground with gypsum. Why do you think gypsum is added?

Maybe to control the setting time?

Yes, that's correct! Adding gypsum helps slow the hydration reaction and manages the setting time of the cement.

Oxide Composition

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s talk about the major oxides present in OPC. Who can list a few of them?

I know lime (CaO) and silica (SiO₂) are important.

That’s right! Lime makes up about 60-67% of the composition. It’s crucial for strength gain. So what happens if there is too much lime?

It could cause problems with soundness, right?

Correct again! What about the role of silica?

It helps form calcium silicate hydrate, which gives the concrete strength.

Exactly! It combines with lime to form C-S-H, the primary strength-giving component in concrete.

Functions of Other Oxides

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s analyze the other oxides like alumina, iron oxide, and magnesia. Who can tell me the role of alumina?

I think it helps with fast setting and lowers the temperatures needed for clinkering.

That’s right! It aids in speed but what might excessive alumina lead to in concrete?

It can make the concrete weak against sulphate attack, right?

Yes! Now, let’s touch on iron oxide. Why do you think it is included in the cement?

Does it enhance the hardness and color?

Precisely! By contributing to the color and hardness of the concrete, it plays an essential role.

Setting and Performance

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let’s connect how these oxides affect cement performance in terms of setting time and durability.

Does more SO₃ mean a longer setting time?

Excellent! Sulfur trioxide helps in controlling the setting time. But if there are high alkalis, what might occur?

It could lead to efflorescence in the concrete.

Correct! That's why understanding the chemical composition is critical for tailoring cement to specific engineering needs.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Understanding the chemical composition of cement, especially Ordinary Portland Cement, is crucial for predicting concrete's physical properties. This section outlines the major oxides found in OPC and their respective contributions to the material's strength, setting time, and durability.

Detailed

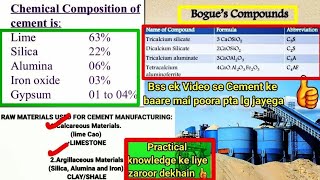

Chemical Composition of Cement

Cement is seminal in concrete technology, serving as the binder that holds various aggregates together and contributes to the overall strength and durability of concrete structures. This section primarily focuses on Ordinary Portland Cement (OPC), the most prevalent type of cement.

Key Points:

- Manufacturing Process: OPC is produced by calcining a mixture of calcareous (lime source) and argillaceous (clay source) materials at approximately 1450°C to form clinker, which is then ground with gypsum to regulate setting time.

- Major Oxides Present: The chemical makeup can be analyzed based on its oxide composition, including:

- Lime (CaO): 60-67% contributes significantly to strength but in excess can lead to unsoundness.

- Silica (SiO₂): 17-25% works with lime to form C-S-H, crucial for strength.

- Alumina (Al₂O₃): 3-8% facilitates quick setting and lowers clinkering temperatures.

- Iron oxide (Fe₂O₃): 0.5-6% provides color and hardness.

- Magnesia (MgO): 0.1-4%, enhances strength at low levels but excess can cause expansion.

- Sulfur trioxide (SO₃): 1-3% helps control setting time.

- Alkalis (Na₂O, K₂O): 0.2-1.3%, affects durability and can lead to efflorescence.

- Functions of Oxides: Each oxide serves particular functions that influence the hydration process and the performance of cement in concrete.

Grasping the chemical composition of OPC allows civil engineers to tailor concrete mixes for specific applications, ensuring durability, strength, and resistance to environmental factors.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Ordinary Portland Cement (OPC)

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Ordinary Portland Cement (OPC), the most commonly used cement in concrete technology, is manufactured by calcining a mixture of calcareous and argillaceous materials at high temperatures (around 1450°C). The resulting product is called clinker, which is then ground with a small amount of gypsum.

Detailed Explanation

Ordinary Portland Cement (OPC) is essential in construction due to its widespread usage. To make OPC, limestone (calcareous material) and clay (argillaceous material) are heated together in a kiln at very high temperatures, around 1450°C. This intense heat causes the materials to chemically react, resulting in a product known as clinker. After cooling, the clinker is finely ground and mixed with a small amount of gypsum to regulate its setting time. This process makes the cement versatile for various construction applications.

Examples & Analogies

Think of the production of cement like baking cookies. Just as you need to mix flour (calcareous), sugar, and eggs (argillaceous material), and then bake them at a certain temperature to create cookies, the same principle applies to making cement. The high-temperature kiln is similar to an oven, turning raw materials into a new product that can be used for construction.

Major Oxides Present in Cement

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Major Oxides Present:

Oxide Symbol Typical Content (%)

Lime CaO 60–67

Silica SiO₂ 17–25

Alumina Al₂O₃ 3–8

Iron oxide Fe₂O₃ 0.5–6

Magnesia MgO 0.1–4

Sulphur trioxide SO₃ 1–3

Alkalis (Na₂O, K₂O) - 0.2–1.3

Detailed Explanation

The chemical composition of cement is primarily defined by several key oxides, each contributing to cement's properties:

- Lime (CaO): The major component, essential for strength. If too much lime is present, it can lead to instability.

- Silica (SiO₂): Combines with lime to form calcium silicate hydrate (C-S-H), which is crucial for providing strength.

- Alumina (Al₂O₃): It assists in setting quickly and lowers the energy required for clinkering.

- Iron oxide (Fe₂O₃): Adds strength and coloring to the cement.

- Magnesia (MgO): Contributes to strength, but excess can cause expansion.

- Sulphur trioxide (SO₃): Influences the setting time.

- Alkalis (Na₂O, K₂O): Affect durability and may lead to efflorescence, which is the formation of white, powdery deposits on concrete surfaces.

Examples & Analogies

Imagine making a special smoothie. Each ingredient, like bananas (lime), berries (silica), and yogurt (alumina), must be present in the right amounts for the smoothie to taste perfect. If you add too much of one thing, like bananas, the smoothie might spoil (just like excess lime can lead to concrete issues). Each component plays a vital role in producing a delicious end result.

Functions of Major Oxides

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Functions of Oxides:

- CaO (Lime): Responsible for strength gain. Excess can cause unsoundness.

- SiO₂ (Silica): Combines with CaO to form strength-giving C-S-H.

- Al₂O₃ (Alumina): Aids in quick setting and reduces clinkering temperature.

- Fe₂O₃ (Iron oxide): Adds hardness and contributes to color.

- MgO: Small amounts add strength; excess causes expansion.

- SO₃ (Sulphur trioxide): Controls setting time.

- Alkalis (Na₂O, K₂O): Affect durability and may cause efflorescence.

Detailed Explanation

Each oxide in cement has specific roles:

- CaO (Lime) is critical for increasing strength; however, too much can destabilize the cement.

- SiO₂ (Silica) works with lime to form calcium silicate hydrate (C-S-H), the primary substance that imparts strength to concrete.

- Al₂O₃ (Alumina) helps the cement set quickly and requires less energy for the manufacturing process.

- Fe₂O₃ (Iron oxide) provides additional hardness and colors the cement.

- MgO is beneficial in moderation, but excess can lead to unwanted expansion issues during setting.

- SO₃ (Sulphur trioxide) helps control how quickly the cement sets after getting mixed with water, which is crucial for managing construction timelines.

- Alkalis (Na₂O, K₂O) have an impact on durability and can cause unsightly efflorescence if not managed correctly.

Examples & Analogies

Think of each oxide as a team member in a sports team. CaO is the strong player that scores goals (strength), SiO₂ is the player that assists in making goals (C-S-H formation), and each of the other oxides has a role that contributes to the team’s overall performance. However, if one player tries to take on too much responsibility (like excess lime or alkalis), it can disrupt the whole team’s game.

Key Concepts

-

Cement Chemistry: Understanding the chemical composition is essential for determining the properties of cement and, consequently, concrete.

-

Oxide Composition: Major oxides in cement include CaO, SiO₂, Al₂O₃, Fe₂O₃, MgO, SO₃, and alkalis, each affecting performance.

-

Hydration Process: The hydration process is crucial as it directly affects setting time, strength gain, and durability.

Examples & Applications

The presence of silica (SiO₂) increases the formation of C-S-H, enhancing concrete strength.

Excess calcium oxide (CaO) can lead to unsound cement over time, impacting the durability of structures.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Cement's not just mud and rock, it's CaO and SiO₂, hard as a block!

Stories

Imagine a magical kitchen where lime (CaO) and silica (SiO₂) mix with water to create a strong, sturdy castle (concrete) that will stand tall for years.

Memory Tools

Remember CASS for the major oxides: C for CaO, A for Al₂O₃, S for SiO₂, and S for SO₃.

Acronyms

Think of the mnemonic FLASH for remembering Fuels, Lime, Alumina, Silica, and Heat as necessary components in producing quality cement.

Flash Cards

Glossary

- Cement

A binding material used in construction, specifically in concrete.

- Ordinary Portland Cement (OPC)

The most commonly used type of cement, made from calcined limestone and clay.

- Clinker

The solid product produced from heating a mixture of raw materials to high temperatures.

- Calcium Silicate Hydrate (CSH)

The primary strength-giving compound formed during the hydration of cement.

- Gypsum

A mineral added to cement during grinding to control the setting time.

- Oxides

Chemical compounds containing oxygen and another element, significant in defining the properties of cement.

Reference links

Supplementary resources to enhance your learning experience.