Types of Cement Based on Chemical Composition

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Rapid Hardening Cement

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we’re starting with rapid hardening cement. Can anyone tell me why it's important in construction?

Because it sets quickly, right?

Exactly! Rapid hardening cement has a high content of Tricalcium Silicate, or C₃S, which leads to this quick strength gain. It’s particularly useful in repairs or precast sections. Now, can anyone think of a practical application for it?

Maybe when they need to reopen a road quickly after repairs?

That's a perfect example! The faster the road can be usable, the better for traffic flow.

Low Heat Cement

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s move to low heat cement. Why do you think this type of cement is designed with lower C₃A and C₃S?

To reduce heat during hydration, I guess?

Correct! This is vital for mass concrete structures, like dams, where excessive heat can cause cracks. Can anyone think of how this might impact the structure?

It could prevent structural failure from cracking due to heat!

Exactly, well said!

Sulphate Resisting Cement

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s talk about sulphate resisting cement. Who can explain why this cement is critical?

I think it’s because it has low C₃A to resist sulphate attacks?

That’s correct! This cement is essential in environments like coastal areas where sulphate exposure is high. What can happen if standard cement is used there?

It could lead to expansion and cracking, right?

Absolutely. Preventing such damage maintains the integrity of structures.

Portland Pozzolana Cement (PPC)

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let’s cover Portland Pozzolana Cement, or PPC. What materials are involved?

It's made with pozzolanic materials, like fly ash, isn't it?

Correct! PPC reduces calcium hydroxide, enhancing durability. Can anyone share why that’s beneficial?

It helps with resistance against chemical attacks, right?

Exactly, boosting the longevity of concrete structures!

White Cement

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let's discuss white cement. What makes it different from ordinary Portland cement?

It has a lower iron oxide content, which keeps it white.

Exactly! This makes it perfect for architectural uses where appearance is crucial. Can anyone think of an example of its application?

Maybe in decorative concrete or sculptures?

Very good! Its aesthetic quality makes it popular in such applications.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section discusses different types of cement classified by their chemical composition, including rapid hardening cement, low heat cement, sulphate-resisting cement, Portland pozzolana cement, and white cement, highlighting their specific uses and advantages in concrete technology.

Detailed

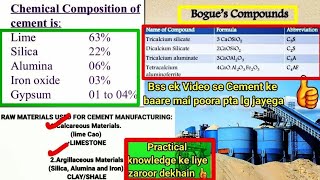

Types of Cement Based on Chemical Composition

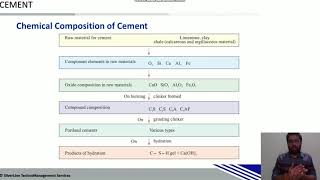

In this section, we examine different types of cement categorized based on their chemical composition. Each type serves specific engineering requirements determined by its material characteristics and the intended use in construction. Here are the key types discussed:

1. Rapid Hardening Cement

- Characteristics: Contains higher amounts of Tricalcium Silicate (C₃S).

- Uses: Ideal for situations where early strength is critical, such as in repairs and precast components.

2. Low Heat Cement

- Characteristics: Has lower Tricalcium Aluminate (C₃A) and Tricalcium Silicate (C₃S) content.

- Uses: Used in mass concrete structures to minimize heat generation during hydration, which reduces the risk of cracking.

3. Sulphate Resisting Cement

- Characteristics: Formulated with very low C₃A.

- Uses: Offers high resistance to sulphate attacks, making it suitable for structures exposed to aggressive environments (such as near seawater or geological sulphate).

4. Portland Pozzolana Cement (PPC)

- Characteristics: Incorporates pozzolanic materials like fly ash.

- Uses: Enhances durability by reducing calcium hydroxide (Ca(OH)₂) content and improving resistance to chemical attacks.

5. White Cement

- Characteristics: Iron oxide levels are minimized to ensure color purity.

- Uses: Primarily used for architectural and aesthetic purposes, where visual appearance is essential.

Conclusion

Understanding the chemical composition and specific uses of different types of cement allows civil engineers to choose the most appropriate material for their construction needs, enhancing durability, strength, and overall performance.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Rapid Hardening Cement

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Rapid Hardening Cement:

- Higher C₃S content.

- Used where early strength is needed.

Detailed Explanation

Rapid hardening cement contains a higher proportion of Tricalcium Silicate (C₃S) compared to other types of cement. This composition allows it to gain strength quickly after mixing with water, making it ideal for projects where early structural integrity is crucial, such as in repairs or fast-track construction.

Examples & Analogies

Imagine you’re baking cookies. If you add baking powder that reacts faster, your cookies will rise more quickly. Similarly, rapid hardening cement reacts swiftly, allowing structures to support weight and function sooner.

Low Heat Cement

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Low Heat Cement:

- Lower C₃A and C₃S content.

- Used in mass concreting to reduce heat.

Detailed Explanation

Low heat cement is formulated with reduced amounts of Tricalcium Aluminate (C₃A) and Tricalcium Silicate (C₃S), which helps to minimize the heat generated during hydration. This is particularly important in large structures, like dams or foundations, where excessive heat can lead to cracking or structural failures.

Examples & Analogies

Think of it like making a large casserole in the oven. If the heat is too intense, the outside may cook too quickly while the inside remains raw. Low heat cement allows for a slower curing process, ensuring even strength across a large area.

Sulphate Resisting Cement

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Sulphate Resisting Cement:

- Very low C₃A.

- High resistance to sulphate attack.

Detailed Explanation

Sulphate resisting cement is specially designed to feature a very low content of Tricalcium Aluminate (C₃A), which makes it resistant to damage from sulphates found in soil and water. This type of cement is essential in environments where these compounds could cause expansion and cracking.

Examples & Analogies

Consider this like waterproof shoes. If you know you'll be walking through puddles, you want shoes that can withstand water without damage. Sulphate resisting cement protects structures from the harmful effects of sulphate exposure.

Portland Pozzolana Cement (PPC)

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Portland Pozzolana Cement (PPC):

- Contains fly ash or pozzolana.

- Reduces Ca(OH)₂ content, improves durability.

Detailed Explanation

Portland Pozzolana Cement is made by mixing ordinary Portland cement with pozzolanic materials like fly ash. This blend enhances the cement's durability by decreasing the calcium hydroxide (Ca(OH)₂) content, which can lead to deterioration. It also results in improved long-term strength and resilience to environmental attacks.

Examples & Analogies

Imagine adding vegetables to a soup to enhance its nutritional value. Just like those vegetables improve the soup’s health benefits, the pozzolanic materials improve the durability of Portland Pozzolana Cement, making concrete stronger over time.

White Cement

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- White Cement:

- Iron oxide content minimized.

- Used for architectural works.

Detailed Explanation

White cement is produced by minimizing the iron oxide content, which gives it a bright white appearance. This type of cement is favored for architectural and decorative applications where aesthetic qualities are important, such as facades, precast concrete products, and artistic designs.

Examples & Analogies

Think of white cement like a blank canvas for an artist. Just as an artist uses a clean, white canvas to create vibrant paintings, builders use white cement to achieve beautiful, clean-looking structures that stand out.

Key Concepts

-

Rapid Hardening Cement: High C₃S content, gains strength quickly.

-

Low Heat Cement: Designed to reduce temperature rise in mass construction.

-

Sulphate Resisting Cement: Low C₃A content protects against sulfate attacks.

-

Portland Pozzolana Cement: Incorporates pozzolanic materials, enhances durability.

-

White Cement: Aesthetic purposes, low iron oxide.

Examples & Applications

Rapid hardening cement is crucial for quick repair jobs to minimize road closure times.

Low heat cement is commonly used in the construction of large dams to prevent cracking from heat.

Sulphate resisting cement is used in coastal structures to withstand the adverse effects of sulphate exposure.

Portland pozzolana cement helps improve the long-term performance of concrete in aggressive chemical environments.

White cement is used in decorative concrete applications for its visual appeal.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

When you need to set strong, it's rapid hardening that's not wrong.

Stories

Once a builder faced a challenge to fix a road fast. He reached for rapid hardening cement, which set strong and was unsurpassed.

Memory Tools

Remember 'R-L-S-P-W' for types of cement: Rapid, Low heat, Sulphate resisting, Portland, White.

Acronyms

For PPC, think 'Pozzolanic Performance Creates' durability.

Flash Cards

Glossary

- Rapid Hardening Cement

Cement that gains strength quickly due to high Tricalcium Silicate content.

- Low Heat Cement

Cement with lower C₃A and C₃S content aimed at reducing heat generation during hydration.

- Sulphate Resisting Cement

Cement specifically designed to resist sulphate attacks due to very low C₃A content.

- Portland Pozzolana Cement (PPC)

Cement containing pozzolanic materials that enhances durability and reduces Ca(OH)₂.

- White Cement

Cement with minimal iron oxide content used for aesthetic architectural applications.

Reference links

Supplementary resources to enhance your learning experience.