Quality Control Tests for Cement Chemistry

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Chemical Tests for Cement Quality

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we’re going to explore the key chemical tests performed on cement to ensure its quality. Let's start with the Loss on Ignition test. Can anyone tell me what this test indicates?

Doesn't it measure the amount of unburnt materials and moisture?

Exactly, Student_1! High values in this test signal poor quality. Now, what about the Insoluble Residue test?

Is it related to the amount of non-reactive particles in the cement?

Yes, Student_2! Non-reactive particles can impact performance during hydration. What about the Sulphur content test?

It helps regulate the hydration of C₃A, right?

Correct! The right amount of sulphur is crucial for managing setting times. Let’s summarize before we move to the physical tests: the four main chemical tests include Loss on Ignition, Insoluble Residue, Sulphur Content, and Free Lime.

Physical Tests for Cement Quality

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's discuss physical tests. One important method is the Blaine's Air Permeability test, which measures what?

It measures the fineness of the cement, and finer cement hydrates faster.

Right you are! Fineness affects hydration rates significantly. How about the Setting Time? What do we measure?

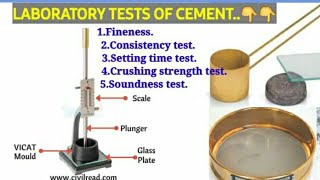

Using the Vicat apparatus, we check how long it takes for the cement to set.

Exactly! It’s critical to regulate the setting time to ensure workability. Once again, let's recap: we have Fineness, Setting Time, Heat of Hydration, and Soundness. These tests are essential to confirm the quality and performance of cement.

Importance of Quality Control Tests

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Why are these quality control tests so crucial? How do you think they impact real-world construction?

If we don't test, the cement might not perform well, leading to failures in structures.

Exactly! That's why each test plays a role in ensuring safety and durability. Can someone highlight a consequence of ignoring these tests?

Unsoundness due to free lime can cause cracking in concrete, which might lead to accidents!

Well said, Student_3! Ignoring quality tests can lead to serious issues. Remember, quality control in cement chemistry is not just about compliance; it’s about safeguarding structures for the future.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Quality control tests for cement chemistry are crucial for verifying the composition and properties of cement. Key tests include chemical tests to detect unburnt materials and physical tests that measure fineness, setting time, and soundness, which collectively ensure cement meets required standards for construction.

Detailed

Detailed Summary of Quality Control Tests for Cement Chemistry

In the field of civil engineering, the quality of cement is fundamental to ensuring the durability and stability of concrete structures. This section presents various quality control tests employed to assess both the chemical and physical properties of cement, which are pivotal in determining its appropriateness for different applications.

1. Chemical Tests:

These tests evaluate the cement's composition, focusing on:

- Loss on Ignition: This test detects the presence of unburnt materials or moisture in cement samples. High loss on ignition indicates poor quality.

- Insoluble Residue: Measures the proportion of non-reactive particles in cement, ensuring the consistent formation of the desired compounds during hydration.

- Sulphur Content (SO₃): Evaluated to regulate the hydration of tricalcium aluminate (C₃A) within the cement, which affects setting time and soundness.

- Free Lime Test: Assesses the soundness of cement by detecting excess free lime, which can lead to expansion and cracking after setting.

2. Physical Tests Related to Chemistry:

These tests focus on how the cement behaves physically, influencing its performance:

- Fineness (Blaine's Method): Related to the surface area of cement, this test indicates the rate of hydration—finer particles hydrate more quickly.

- Setting Time (Vicat Apparatus): Measures the time it takes for cement to transition from a fluid state to a rigid form, affected significantly by gypsum content and C₃A.

- Heat of Hydration: Measured using calorimetry, it quantifies the heat released during the hydration process, which is crucial in large concrete structures to prevent cracking.

- Soundness Test (Le Chatelier Method): Detects issues due to expansion from free lime or excess MgO in cement, vital for long-term durability.

Overall, these quality control tests ensure that the cement meets the necessary chemical composition and physical performance standards required for safe and effective construction practices.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Chemical Tests for Cement

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Chemical Tests:

- Loss on ignition: Detects unburnt materials or moisture.

- Insoluble residue: Measures non-reactive particles.

- Sulphur content (SO₃): Assessed for regulating C₃A hydration.

- Free lime test: Ensures soundness.

Detailed Explanation

This chunk discusses chemical tests that are performed to ensure the quality of cement.

- Loss on Ignition: This test measures how much weight the cement loses when it is heated. A high loss indicates the presence of unburnt materials or moisture, which can affect the quality of cement.

- Insoluble Residue: This test is used to find out the amount of non-reactive material in cement. Ideally, we want minimal insoluble residue because it does not contribute to the binding properties of the cement.

- Sulphur Content (SO₃): Sulphur is important for controlling the hydration process of tricalcium aluminate (C₃A). Too much sulphur can lead to adverse reactions, so this test ensures it stays within controlled limits.

- Free Lime Test: This test checks for the presence of free lime (uncombined calcium oxide) which can lead to expansion and cracking. Ensuring there is minimal free lime helps maintain the stability and durability of the cement over time.

Examples & Analogies

Think of quality control tests for cement as the checks you might perform before baking a cake. Just as you would check that all your ingredients are fresh and measured correctly, cement manufacturers perform these tests to ensure that the chemical properties of the cement are balanced and suitable for strong construction.

Physical Tests Related to Chemistry

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Physical Tests Related to Chemistry:

- Fineness (Blaine's method): Related to hydration rate.

- Setting Time (Vicat apparatus): Affected by gypsum and C₃A.

- Heat of Hydration: Measured using calorimetry.

- Soundness Test (Le Chatelier method): Detects free lime or MgO expansion.

Detailed Explanation

This chunk explains physical tests that are important for evaluating cement's performance:

- Fineness (Blaine's Method): This measures the surface area of cement particles. Finer particles have a larger surface area which increases the rate of hydration, leading to quicker setting times.

- Setting Time (Vicat Apparatus): This test measures the time it takes for cement paste to transition from a fluid to a solid state. The addition of gypsum and the chemistry of the cement (like the amount of C₃A) directly influence this time.

- Heat of Hydration: This test assesses the heat generated when cement reacts with water, which is important for understanding its behavior in massive structures. Excessive heat can lead to cracking in large structures like dams.

- Soundness Test (Le Chatelier Method): This test checks for potential expansion due to any free lime or excess magnesium oxide. If unchecked, this can lead to cracking and structural issues after hardening.

Examples & Analogies

Consider these physical tests as the way a coach evaluates a player’s readiness for a game. Fineness is like assessing how fit they are by looking at every aspect of their performance. Setting time can be compared to measuring how quickly they can adapt under pressure. Heat of hydration reflects their stamina in long matches, and soundness testing is similar to ensuring they do not overexert themselves causing injury.

Key Concepts

-

Chemical Tests: Include Loss on Ignition, Insoluble Residue, Sulphur Content, and Free Lime tests that assess the composition of cement.

-

Physical Tests: Incorporate methods like Blaine's test for fineness, Vicat apparatus for setting time, and calorimetry for heat of hydration.

-

Importance: Quality control tests ensure that concrete is reliable, safe, and meets specific engineering standards.

Examples & Applications

If the Loss on Ignition test indicates a high percentage of unburnt material, it suggests that the cement may not have been adequately processed, impacting strength.

Inadequate control of setting time can lead to flash setting, making the concrete unusable in construction.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In cement, we measure all the tests, ensure its quality, we do our best.

Stories

Imagine a builder with a pile of cement, measuring for unburnt bits before they cement.

Memory Tools

Remember the acronym 'CLIF': C for Chemical tests, L for Lime test, I for Insoluble residue, F for Fineness.

Acronyms

CFS

Chemical tests

Fineness tests

Setting time tests

all essential to ensure good cement.

Flash Cards

Glossary

- Loss on Ignition

A test that measures the amount of unburnt materials or moisture remaining in the cement after heating.

- Insoluble Residue

Non-reactive particles in cement that can affect its performance during hydration.

- Sulphur Content

The amount of sulphur trioxide (SO₃) in cement, which regulates the hydration of tricalcium aluminate.

- Fineness

A measurement of the size of cement particles, influencing the rate of hydration.

- Setting Time

The time it takes for cement to transition from a fluid to a rigid state.

- Soundness

The ability of cement to maintain its volume and not expand excessively after setting.

Reference links

Supplementary resources to enhance your learning experience.