Ductile Detailing Provisions (IS 13920)

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

General Requirements

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we are going to explore the general requirements for ductile detailing as outlined in IS 13920. Why do you think ductile detailing is important for buildings in earthquake-prone areas?

I think it helps buildings withstand shaking without collapsing.

Exactly! Structures in Zones III, IV, and V are required to implement these provisions. What are the consequences of not following these guidelines?

They could fail during an earthquake, putting lives at risk.

Correct! Ductile detailing ensures not just survival, but also the integrity of the building during seismic events.

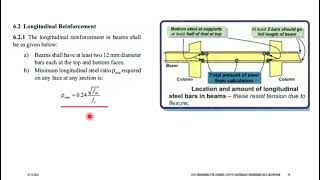

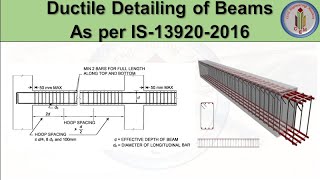

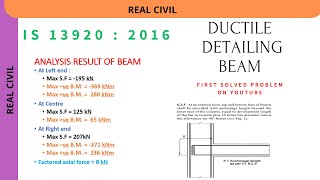

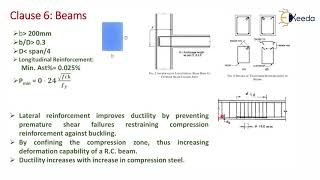

Beam Detailing

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s dive into beam detailing. What do you think are some key guidelines for detailing beams?

I’ve heard there are limits on the amount of reinforcement.

That's right! We establish minimum and maximum limits for reinforcement. Can anyone tell me why lap splices aren’t allowed in the joint region?

It’s to maintain strength and prevent weak points in the beam!

Exactly! And we must also closely space stirrups near beam ends to prevent shear failure. Remember the acronym 'LIMBS' - 'Limits, No laps, Minimum stirrups, Beam ends, Shear reinforcement.'

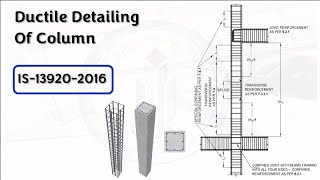

Column Detailing

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's shift our focus to columns. What’s a critical limit for ductile columns regarding their axial load?

It’s limited to 0.4fckAg!

Correct! This ensures that the column behaves properly under seismic loads. How are the ties arranged in plastic hinge zones?

They need to be closely spaced to help with the confinement of the concrete.

Good observation! And this is essential for making sure that columns remain strong while beams yield. Remember 'CCT' - 'Column Capacity, Closely tie'.

Joint Detailing

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let’s discuss joint detailing. Why do you think anchorage of longitudinal bars in joints is so critical?

To maintain the connection between beams and columns during earthquakes.

Exactly! Joints are like the heart of a structure, transmitting forces across the system. How are stirrups utilized in these joints?

Stirrups are provided through joints to enhance their strength.

Perfect! Stirrups through joints indeed add to the structural integrity during seismic events.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The Ductile Detailing Provisions section emphasizes the importance of reinforcing concrete structures in zones III, IV, and V to ensure better performance during seismic events. It covers specific detailing guidelines for beams, columns, and joints, with a focus on reinforcement limits, anchorage, and the overall design philosophy of strong columns and weak beams.

Detailed

Ductile Detailing Provisions (IS 13920)

In earthquake-prone areas, the ductile detailing of reinforced concrete (RC) structures is critical for ensuring that buildings can deform without collapsing under seismic loads. IS 13920 outlines mandatory provisions for structures situated in higher seismic zones (III, IV, and V), detailing specific requirements for beams, columns, and joints.

Key Components:

- Beam Detailing: Specifies minimum and maximum reinforcement, prohibits lap splices within joint regions, and requires closely spaced stirrups at beam ends for shear reinforcement.

- Column Detailing: Establishes that axial load-carrying capacity for ductile columns is limited to 0.4fckAg. Stipulations include closely spaced ties in plastic hinge zones and adherence to the strong column-weak beam principle, which ensures that columns remain elastic while beams yield.

- Joint Detailing: Focuses on providing stirrups through joints, ensuring full anchorage of longitudinal bars which is essential for the integrity of the structure during seismic activities.

These provisions are crucial in enhancing the energy dissipation capacity during an earthquake, thereby preventing catastrophic failure.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

General Requirements

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Mandatory for structures in Zone III, IV, and V.

• Applies to RC buildings designed with SMRF systems.

Detailed Explanation

This chunk discusses the conditions under which ductile detailing provisions become mandatory. Specifically, structures located in seismic Zones III, IV, and V are required to follow these provisions. These zones are classified based on their risk of seismic activity, with Zone I being the lowest risk and Zone V the highest. Additionally, the requirements apply specifically to reinforced concrete (RC) buildings that are designed using special moment-resisting frame (SMRF) systems, which are designed to absorb and dissipate energy during seismic events.

Examples & Analogies

Think of ductile detailing like safety features in a car. Just as some cars are built with enhanced safety systems to better protect passengers in case of an accident (like crumple zones and airbags), buildings in high-risk areas have to be designed with features that help them withstand earthquakes. Just as you wouldn’t drive a regular car in a demolition derby, you wouldn’t build a structure in a seismic zone without these extra safety measures.

Beam Detailing

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Minimum and maximum reinforcement limits.

• Lap splices not permitted in the joint region.

• Shear reinforcement: Closely spaced stirrups near beam ends.

Detailed Explanation

Beam detailing focuses on the specific requirements for reinforcing beams in structures. Minimum and maximum reinforcement limits ensure that the beams have enough strength and ductility to withstand seismic forces. Lap splices, which are used to connect two pieces of rebar, are not allowed in the joint regions to prevent weaknesses during seismic events. Additionally, closely spaced stirrups, which provide shear strength, are mandated near the ends of beams to enhance their durability against shear failures during an earthquake.

Examples & Analogies

Covering a fragile item with layers of bubble wrap for extra protection is similar to beam detailing. Just as strong wrapping limits the chances of damage when the item is dropped, the specific reinforcement requirements ensure that beams in buildings retain their integrity when faced with the shaking associated with earthquakes.

Column Detailing

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Axial load carrying capacity limited to 0.4fckAg for ductile columns.

• Transverse reinforcement: Closely spaced ties in plastic hinge zones.

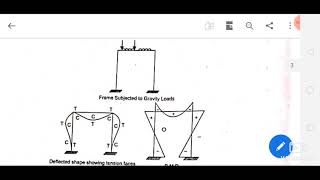

• Strong column-weak beam design principle.

Detailed Explanation

Column detailing is essential for ensuring that columns can effectively support loads during seismic activity. The axial load carrying capacity for ductile columns is limited to a certain percentage of their concrete strength, denoted by 0.4fckAg, where fck is the characteristic compressive strength of concrete and Ag is the gross area of the column. This limitation is in place to ensure adequate ductility. Furthermore, transverse reinforcement, composed of closely spaced ties, must be provided in areas known as plastic hinge zones, which are expected to undergo significant deformation during an earthquake. The 'strong column-weak beam' principle is another crucial concept; it ensures that in the event of deformations, the beams yield before the columns to prevent overall structural failure.

Examples & Analogies

Imagine you’re building a tower out of LEGO. If you want it to stand tall and not fall over easily, you’ll want to make sure the base (columns) is strong enough to support the weight of the upper parts (beams). But if the upper parts are too heavy, they could crush the base. Hence, you make the base strong and the upper parts flexible, ensuring that if something goes wrong (like a quake), it fails in a controllable way, like the top breaking off instead of the entire tower tumbling down.

Joint Detailing

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Stirrups provided through joints.

• Ensure full anchorage of longitudinal bars.

Detailed Explanation

Joint detailing refers to the requirements for the connections between beams and columns, which are critical points in a structure under seismic stress. Stirrups must be installed through the joints to enhance the structural integrity and prevent failures during seismic events. Additionally, it is vital to ensure that the longitudinal bars are fully anchored, which means that they must be adequately secured to transfer stresses effectively without slipping or separating, thereby maintaining the strength of the connection during seismic events.

Examples & Analogies

Consider joints in a bridge as the bolts that hold different parts together. If these bolts are loose, the bridge becomes unstable and could collapse under stress. Similarly, ensuring that stirrups are secured in joints acts like tightening the bolts, reinforcing the connections and ensuring that the structure can endure the forces acting upon it during an earthquake.

Key Concepts

-

Ductile Detailing: Enhancing seismic resistance via detailed reinforcement in concrete structures.

-

Beam Detailing: Specific requirements for reinforcement limits and shear strength.

-

Column Detailing: Limitations on axial load and the need for closely spaced ties.

-

Joint Detailing: Requirements for stirrups and anchorage in joints.

Examples & Applications

Implementing closely spaced stirrups in beams to prevent shear failure during an earthquake.

Following the strong column-weak beam design philosophy to ensure columns remain safe while beams can yield.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In a quake, with ductile form, beams will yield, while columns stay warm.

Stories

Imagine a building during an earthquake, the beams sway but stay in shape, while the columns stand tall, all thanks to the caring design of ductile detailing.

Memory Tools

Remember 'BJC!' - Beam detailing, Joint anchorage, Column constraints.

Acronyms

CST - Columns Strong, Ties tight.

Flash Cards

Glossary

- Ductile Detailing

The practice of designing reinforcement in concrete structures to ensure they can undergo significant deformation without failure in seismic zones.

- Seismic Zone

Regions classified by their risk of earthquake activity.

- Lap Splices

A method of joining two reinforcing bars together by overlapping them.

- Plastic Hinge Zone

The area in beams and columns where significant plastic deformation occurs during seismic movements.

- Shear Reinforcement

Additional reinforcement added to concrete structures to resist shear forces.

- Strong ColumnWeak Beam Principle

A design approach where columns are designed to remain elastic, while beams are allowed to yield.

Reference links

Supplementary resources to enhance your learning experience.