Analyte Losses in Chemical Analysis

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Analyte Losses

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will discuss the issue of analyte losses in chemical analysis. Can anyone tell me why this is an important topic?

I think it's important because it can affect the accuracy of our results.

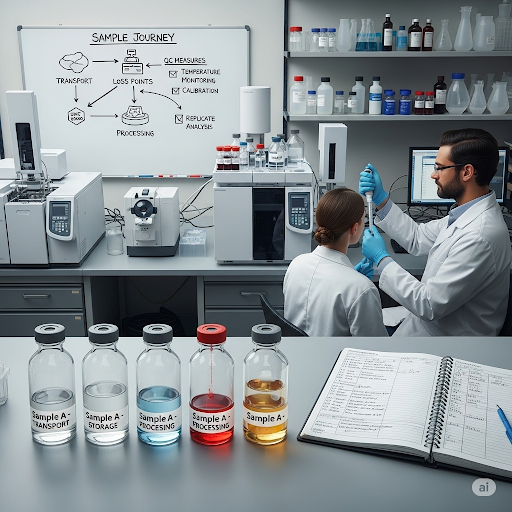

Exactly! Analyte losses can lead to inaccurate data which can be critical when making environmental decisions. There are four main stages where losses can occur: transportation, storage, processing, and analysis.

So, what are the main causes of these losses?

Great question! They primarily include volatilization, reactions with other materials, and adsorption to surfaces. Let's start with volatilization. Who can tell me what that means?

Isn't it when the analytes evaporate from the sample?

That's right! Keeping samples in airtight containers helps reduce this loss. Remember, we can think of 'volatilization' as 'vapor loss'—a mnemonic to help us remember.

What about reactions? How do they cause loss?

Reactions can lead to biodegradation over time. It’s essential to analyze samples quickly to avoid losing your substances of interest. Keeping this in mind is crucial for maintaining data integrity.

Mechanisms of Analyte Loss

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s dive deeper into the mechanisms of analyte loss. What do we understand by adsorption?

It's when the analytes stick to the surfaces of containers, right?

Correct! This can happen due to the nature of the container itself. For instance, using glass for organic samples can reduce losses. What's a useful tip to remember how to choose containers?

We should use inorganic containers for organic samples!

Exactly! The choice of container material is a key point. Now, let’s think about how we can mitigate losses from reactions. How can we minimize biodegradation?

By analyzing the samples quickly and keeping them at low temperatures?

Right! Low temperatures slow down reactions significantly, helping to preserve our analytes. Good memory tip: Remember 'cooler is safer' for sample preservation.

Quality Control Measures

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Having identified the mechanisms of loss, how can we ensure the reliability of our results?

By implementing quality control measures?

Precisely! Consistent quality control helps to mitigate the risk of analyte losses. What are some methods of quality control we can employ?

We can use laboratory control samples and surrogate standards.

Very good! Laboratory control samples help us gauge recovery efficiency. Can anyone explain what surrogate standards are?

They're similar compounds that help track the efficiency of our extraction?

Exactly! They provide an indirect measure of the analyte recovery. Also, matrix spikes can be utilized to understand how the matrix affects our results. The key point is minimizing errors at every stage.

Summary and Importance of Analyte Loss Management

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Alright everyone, to conclude, why do you think managing analyte losses is crucial for chemical analysis?

It ensures our environmental assessments are accurate and reliable!

Exactly! Inaccurate data can lead to poor decision-making which impacts our environment. Can anyone recall the key loss mechanisms we discussed?

Volatilization, reactions, and adsorption!

Great memory! So remember the importance of choosing the right containers, analyzing quickly, and implementing quality control procedures—these are all vital for accurate chemical analysis results.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Analyte losses during environmental chemical analysis can occur at various stages: transportation, storage, processing, and analysis. The section details primary causes of these losses—volatilization, reaction, and adsorption—and outlines quality control practices to mitigate these challenges. Understanding these factors is crucial for improving data reliability in environmental assessments.

Detailed

Analyte Losses in Chemical Analysis

This section explores the crucial concerns surrounding analyte losses that can happen during chemical analysis, particularly in environmental contexts. Analyte losses occur at several stages:

- Transportation: Errors may arise while moving samples from the collection point to the laboratory, risking loss of volatile compounds.

- Storage: Improper storage conditions can exacerbate losses due to environmental exposure.

- Processing: The analytical procedure itself can lead to loss through reactions or incomplete extraction.

- Instrument Analysis: Instruments may introduce inherent losses due to their settings or efficiencies.

Key Loss Mechanisms:

- Volatilization: This process refers to the evaporation of analytes from samples, particularly evident in water samples exposed to air. Techniques to mitigate this involve using airtight containers and minimizing headspace.

- Reactions: Analytes may undergo degradation (biodegradation) or react with other sample constituents, necessitating speedy analysis after collection.

- Adsorption: Losses can also occur due to analytes binding to container surfaces, with suggestions like using inert containers to minimize these incidents.

Quality Control Measures:

- Implementing standard operating procedures with quality control protocols ensures reduction in analyte losses. Techniques include laboratory control samples, surrogate standards, and matrix spikes.

- Recoveries are assessed, allowing analysts to understand analyte amounts properly and adjust measurements accordingly.

Overall, the section emphasizes understanding these processes is paramount for environmental analysis to maintain accuracy and reliability in measurements, crucial for informed decision-making.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Importance of Analyte Losses

Chapter 1 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

One of the concerns in chemical analysis for environmental samples is the issue of analyte losses. This is important from the point of view of the confidence people have in the measurement and because this is also subject to litigation. The analysis that people do are used for important decisions, and therefore people would like to have some kind of confidence in terms of the accuracy of the results.

Detailed Explanation

Analyte losses refer to the decrease in the amount of a chemical substance being tested. This is significant because when samples are analyzed, any loss can affect the perceived concentration of a substance, leading to potentially inaccurate results. If results are inaccurate, they can lead to incorrect decisions, especially in environmental contexts where pollution levels are being assessed. The accuracy of these measurements must be upheld to ensure public trust and meet legal standards. Analysts bear the responsibility of ensuring that their methods minimize these losses to maintain confidence in their findings.

Examples & Analogies

Think of this like baking a cake where you need a specific amount of sugar for the perfect sweetness. If you accidentally spill some sugar before it goes into the bowl, the final cake will taste less sweet than intended. In the same way, if chemicals are lost during testing, the results will not reflect the true situation.

Stages of Analyte Loss

Chapter 2 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The possible analyte losses occur first in the transportation of the sample, second, which occur in the storage, then in processing, and fourth in the analytical instrument itself or the chemical analysis instrument.

Detailed Explanation

Analyte losses can occur at various stages during the sampling and analysis process. Firstly, during transportation, samples may be exposed to environmental conditions that lead to losses. Secondly, while being stored, samples may react or degrade, further reducing analyte levels. Thirdly, during processing, if not handled correctly, additional losses may occur. Finally, while being analyzed, instruments might not capture all the analyte, leading to discrepancies. Understanding these points is crucial for developing effective strategies to minimize losses.

Examples & Analogies

Imagine transferring fragile objects, like glass sculptures. If they are not packed properly during transport, some pieces might break. Similarly, while transferring samples for analysis, improper handling can lead to loss of important analytes, just like the sculptures.

Common Processes Leading to Analyte Loss

Chapter 3 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

One of the main processes that result in losses is volatilization, which is evaporation of the sample. The second part of it is reaction, which could be biodegradation or reaction with other entities in the system. Third one is adsorption, which occurs through any solid surface during the processing.

Detailed Explanation

Analyte losses can occur through multiple mechanisms. Volatilization involves the evaporation of chemicals into the atmosphere, which can result in the sample losing valuable components. Reactions can happen when analytes interact with other substances in the sample, leading to degradation or transformation. Lastly, adsorption occurs when analytes cling to solid surfaces, such as the walls of containers, which contributes to inaccuracies in measured concentrations. Each of these processes highlights the importance of careful handling and planning in analytical chemistry.

Examples & Analogies

Imagine marbles in a bag. If you open the bag outdoors, some marbles (analytes) might roll away (volatilization), while others might stick to the bag's insides (adsorption), making it hard to count how many are really there. Just like you need to take care of marbles, we need to protect and accurately measure analytes in chemical analysis.

Strategies to Minimize Analyte Loss

Chapter 4 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

To reduce losses from volatilization, airtight containers should be used, and samples should be stored at low temperatures. For adsorption, using inert materials for containers can minimize the chances of chemical attachment to surfaces.

Detailed Explanation

To minimize analyte losses, analysts must use strategies tailored to each potential loss process. For volatilization, storing samples in airtight containers prevents the compounds from escaping into the air. Additionally, maintaining lower temperatures can slow down the rates of reactions and biodegradation. Using inert materials, like glass for organic chemicals or specific plastic for inorganics, can prevent adsorption onto the container's surfaces, helping retain more analytes within. Implementing these practices ensures that the results from analyses are as close as possible to the true values.

Examples & Analogies

Think of storing leftovers in a well-sealed container in the fridge. This prevents the food from drying out (volatilization) and helps it stay fresh longer. Similarly, scientists use airtight containers to protect their samples and keep their analytes safe.

Checking for Analyte Loss

Chapter 5 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

To estimate analyte loss, we check the recovery efficiency by using a standard that was originally part of the sample to compare against the measured concentration.

Detailed Explanation

Analysts can use recovery efficiency to assess analyte loss by comparing the concentration of recovered analytes after analysis to the initial known concentration. By applying a standard known amount of a substance to samples and then measuring how much of that substance is recovered, analysts can calculate the percentage of analyte lost during the entire process. This information is crucial because it allows for corrections to be made in future analyses, ensuring accuracy in environmental monitoring.

Examples & Analogies

Imagine checking the mileage of your car. If you know your car's fuel tank can hold 50 liters and you refill it to 30 liters, you expect around 20 liters to be used. If there's less than expected when refilling, you know fuel is being wasted somewhere. Knowing this helps you adjust your driving habits to reduce waste, just as analysts adjust their methods to minimize analyte loss.

Matrix Effects and Methods of Recovery

Chapter 6 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

When calculating recovery, matrix effects must be accounted for, so using actual samples and adding standards or using surrogate standards can aid in achieving more accurate results.

Detailed Explanation

Matrix effects refer to any influence other substances within the sample may have on the analysis. These can skew recovery rates, making it difficult to ascertain true analyte concentrations. Analysts can combat this by using standards assimilated into sample sizes or surrogate standards closely related to the analytes but not actually containing them. This way, they gauge recoveries more accurately given that they are aware of potential matrix effects that could impact their results. By refining these strategies, the precision of chemical analyses can be improved.

Examples & Analogies

Think about cooking a special dish while surrounded by different spices. If you accidentally add too much of a strong spice, it could overshadow the main flavors. In analytical testing, if the sample contains unexpected compounds, they could interfere with the measurement of analytes, just like the spice can change the balance of the dish.

Key Concepts

-

Volatilization: The evaporation of analytes from samples which can lead to loss during transport.

-

Reactions: Chemical changes that can cause analytes to degrade over time, especially in organic compounds.

-

Adsorption: Loss of analytes due to attachment on container surfaces, requiring careful choice of materials.

-

Quality Control Measures: Procedures like using control samples and surrogate standards to minimize analyte loss.

Examples & Applications

Using airtight glass containers for transporting water samples minimizes volatilization during transit.

Adding a surrogate standard, such as a similar organic compound, to monitor recovery efficiencies during analysis.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

To keep your sample tight, keep it airtight—avoid loss day and night!

Stories

Imagine a young scientist who uncovers the secret of keeping samples sealed, ensuring no precious analytes wanders away, thus deriving reliable conclusions and supporting environmental policies.

Memory Tools

Remember VRA (Volatilization, Reactions, Adsorption) to keep analyte losses in check.

Acronyms

SIMPLE (Surrogate, Internal standards, Matrix spikes, Control samples, Lab evaluations) for quality control measures.

Flash Cards

Glossary

- Analyte

A substance or chemical component analyzed in a sample.

- Volatilization

The process of a substance converting from liquid to vapor, leading to loss in concentration.

- Biodegradation

The breakdown of organic substances by microorganisms, which can lead to analyte loss.

- Adsorption

The process in which molecules adhere to the surfaces of solids, potentially leading to losses in sample concentration.

- Surrogate Standard

A chemically similar compound added to a sample to compare and assess the extraction efficiency.

- Matrix Spike

A method where a known quantity of analyte is added to a sample to evaluate recovery after analysis.

Reference links

Supplementary resources to enhance your learning experience.