Coefficient of Discharge in Nozzles

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Coefficient of Discharge

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will explore the coefficient of discharge in nozzles, which helps us understand how fluids behave under different conditions.

What exactly is the coefficient of discharge?

Great question! The coefficient of discharge (Cd) is a ratio that corrects the theoretical flow calculated by Bernoulli's equation to reflect actual flow, typically resulting in values between 0.6 and 1.

Why is it important in engineering?

It’s crucial for accurate predictions of fluid flow in practical applications, ensuring designs work effectively under real-world conditions.

Application of Bernoulli’s Equation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

To understand the coefficient, we need to delve into Bernoulli's equation. Can anyone tell me what variables are involved?

It relates pressure, velocity, and height, right?

Exactly! P + 0.5ρv^2 + ρgh = constant. It's important for energy balance in fluid flow.

What assumptions do we make when using this equation?

We assume steady, incompressible, and frictionless flow. However, real-world applications often require adjustments.

Limitations of Bernoulli's Equation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s discuss some limitations of Bernoulli's equation. Who can name a few?

It doesn't work well in unsteady flows or near solid surfaces.

Correct! Frictional effects near solids and at mixing zones prevent its application. What else?

Can it be used when there are pumps or turbines?

Good point! Bernoulli’s equation can handle these scenarios but needs careful application to account for energy gains or losses.

Understanding Flow Behavior

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s visualize fluid movement. Imagine combining fluid balls along streamlines. Why do you think this visualization helps?

It makes it easier to understand how fluid flows and interacts at different points.

Exactly! By visualizing streamlines, we can better apply Bernoulli's equation and understand flow variations at different heights.

How do we calculate actual velocities with the discharge coefficient?

You would modify the theoretical velocity derived from Bernoulli’s equation with Cd to account for real-world losses. Remember that Cd usually ranges from 0.6 to 1!

Practical Applications in Engineering

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Lastly, let’s look at practical applications. Can anyone give an example where the coefficient of discharge is essential?

It’s crucial in designing water distribution systems!

Absolutely! Accurate flow calculations ensure pressure requirements are met in engineering systems.

I think it also affects how we design nozzles in jet engines.

Exactly! Understanding flow dynamics greatly influences performance in such systems. Great engagement today, everyone!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

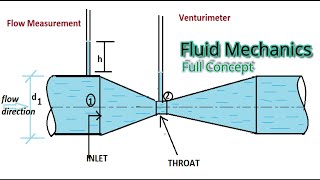

The section introduces the concept of the coefficient of discharge in nozzles, explaining its significance in fluid mechanics. It covers the application of Bernoulli's equation, the assumptions involved, the limitations of Bernoulli's principle, and how the flow behavior in nozzles can be understood through the visualization of virtual fluid balls.

Detailed

In this section, we explore the coefficient of discharge (Cd) in nozzles and its relationship with the principles of fluid dynamics. The section begins with a discussion of Bernoulli's equation, which relates the pressure, velocity, and elevation in a fluid flow system. A key point is the model of virtual fluid balls, which can simplify understanding fluid behavior as they move along streamlines. The assumptions necessary for applying Bernoulli's equations, such as steady and incompressible flow as well as frictionless conditions, are detailed. Limitations such as the applicability of the equation near solid surfaces or within mixing zones are also highlighted. The section concludes with the significance of the coefficient of discharge, which adjusts for non-ideal conditions encountered in actual fluid flow scenarios. The coefficient, ranging from 0.6 to 1.0, helps estimate flow rates more accurately by accounting for energy loss in the system.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Understanding the Basics of Nozzle Discharge

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Whenever you apply the Bernoulli equation, you should draw the streamlines. You should visualize how the fluid moves.

Detailed Explanation

In fluid mechanics, the Bernoulli equation is a fundamental principle that relates the speed of a fluid to its potential energy and pressure. To effectively apply this equation, one must visualize the flow of the fluid through streamlines, which represent the path followed by particles of the fluid. By understanding the flow direction and pressure at different points along these streamlines, you can accurately use the Bernoulli equation to solve for unknown variables like velocity or pressure.

Examples & Analogies

Imagine a river flowing in a smooth curve. The water at the outer edge of the curve moves faster than the water on the inside. Just as you could visualize the path a leaf would take as it floats downstream along this curve, engineers draw streamlines to understand how fluid moves and where to apply the Bernoulli principles.

Assumptions of Bernoulli's Equation

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Bernoulli equations can be applied for unsteady flow, but the simplified derivations are for steady flow.

Detailed Explanation

Bernoulli's equation is based on certain assumptions to simplify calculations. It applies mainly to steady flow, where the fluid's velocity at a point does not change over time. This means that while you can theoretically use Bernoulli's equation for unsteady flow, the derivations and solutions are often only valid for steady-state conditions. Understanding these assumptions is essential because applying the equation outside these contexts can lead to incorrect conclusions about the system.

Examples & Analogies

Think about riding a roller coaster. When the ride is steady and predictable (like steady flow), you can easily determine how fast you’ll go at various parts of the ride. However, if the roller coaster suddenly changes speed or direction unpredictably (like unsteady flow), it becomes harder to predict the experience. Similarly, using Bernoulli's equation effectively requires understanding its limitations.

Coefficient of Discharge (Cd)

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The coefficient of discharge, Cd, typically ranges from 0.6 to 1.0. Theoretically, there are no energy losses.

Detailed Explanation

The coefficient of discharge (Cd) is an important factor when calculating the flow of fluid through nozzles. This coefficient accounts for the fact that in real-world applications, some energy is lost due to friction and other factors. If Cd is equal to 1.0, it means the flow is ideal and there are no losses. However, in practice, the value usually falls between 0.6 and 1.0, reflecting energy losses due to turbulence or non-uniform pressure distributions. Knowing this helps engineers design more accurate systems.

Examples & Analogies

Consider a garden hose. When you turn on the water, it flows smoothly at first, but then you notice that the water pressure decreases if you block part of the nozzle with your thumb. This blockage creates turbulence and resistance, similar to how real-world conditions introduce inefficiencies in fluid flow. The coefficient of discharge reflects these types of inefficiencies in nozzle design.

Applying Bernoulli's Equation to Nozzles

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Using Bernoulli's equations allows us to find relationships between nozzle discharge velocity and height.

Detailed Explanation

When applying Bernoulli's equation to a nozzle, we can relate the height of fluid in a tank to the velocity of fluid discharging through the nozzle. By considering the potential energy (due to height) and converting this energy into kinetic energy (due to motion), we can derive formulas that provide the discharge velocity of the fluid as it exits the nozzle. This process illustrates how energy conservation principles govern fluid dynamics in this scenario.

Examples & Analogies

Think of this as a slide at a playground. The higher you start (like the height of fluid in a tank), the faster you go when you reach the bottom. The slide converts your potential energy (from height) into kinetic energy (speed). Similarly, the height of the fluid in a nozzle influences how fast it will flow out, which we can analyze using Bernoulli's principles.

Key Concepts

-

Coefficient of discharge (Cd): Ratio that corrects theoretical flow predictions to account for practical losses.

-

Bernoulli's equation: Fundamental equation in fluid dynamics that connects pressure, velocity, and elevation.

-

Streamlines: Visual representation of fluid paths which aid in understanding fluid flow behavior.

-

Incompressible flow: Flow condition where fluid density is constant.

-

Frictionless flow: Idealized flow scenario free from viscous losses.

Examples & Applications

In industrial applications, the design of sprinkler systems relies on the coefficient of discharge to ensure adequate coverage.

Jet engines must accurately assess the coefficient of discharge to optimize thrust and fuel efficiency.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Flow through a nozzle, nice and neat, Cd will make our estimates complete.

Stories

Imagine a fluid ball traveling gracefully through a pipeline, only to encounter a bumpy surface that slows it down – this is where understanding Cd becomes essential.

Memory Tools

Remember ABC: A stands for Assumptions made (steady, incompressible, frictionless), B for Bernoulli's equation, and C for Coefficient of discharge.

Acronyms

Use the acronym 'FIVE'

Frictionless

Incompressible

Velocity

Energy – key principles of applying Bernoulli’s equation.

Flash Cards

Glossary

- Coefficient of discharge (Cd)

A ratio that corrects the theoretical discharge calculated by Bernoulli’s equation to account for actual energy losses in flow.

- Bernoulli's equation

An equation that relates pressure, velocity, and elevation in fluid flow systems, assuming certain conditions including steady and incompressible flow.

- Virtual fluid balls

A conceptual model used to visualize fluid movement along streamlines.

- Incompressible flow

A type of flow where the fluid density remains constant throughout the flow field.

- Frictionless flow

An idealized flow condition where there are no viscous forces acting on the fluid.

- Energy loss

The reduction in mechanical energy as fluid flows due to viscosity, turbulence, and other factors.

Reference links

Supplementary resources to enhance your learning experience.