GROUTING

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Grouting Techniques

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're diving into grouting techniques used for soil improvement. Let's start by discussing the importance of these methods in enhancing liquefiable grounds. Can anyone tell me why it's crucial to stabilize these areas?

It's important because liquefaction can cause buildings and infrastructures to fail during earthquakes.

Exactly! The three main methods we’ll explore are compaction grouting, permeation grouting, and jet grouting. Remember the acronym 'CPJ' to help you recall them. Next, let’s talk about compaction grouting.

Compaction Grouting

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Compaction grouting involves injecting a stiff cement grout to increase soil density. What are some specific categories of treatment this method can be applied to?

It can treat soil under existing structures and in urban areas.

Also in narrow areas, I think!

Great recall! So, compaction grouting is very versatile. The injection process pushes surrounding soil, improving its density without significant disturbance. Now, how is the process executed?

I believe it involves using pipes to inject the grout in stages?

Correct! The injection happens step-by-step, lifting the pipes after each injection. Remember this process—'Inject, Lift, Repeat'—as a mnemonic!

Permeation Grouting

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next up is permeation grouting. Can anyone explain what makes this method unique compared to compaction grouting?

It uses a low-viscosity fluid that fills soil pores without altering the soil structure.

Exactly, well said! The goal here is to stabilize the soil particles and waterproof the ground. Think of it as 'filling the gaps' rather than compressing. What is one key advantage of this grouting method?

It creates minimal surface disruption, making it perfect for urban applications.

Absolutely! Just remember, permeate means to 'soak in'—it emphasizes the method's non-invasive nature.

Jet Grouting

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's transition to jet grouting. Who can describe how jet grouting functions?

It uses high-pressure jets to inject a cement mixture and replace the existing soil.

Yeah, and it can also help with groundwater management!

Exactly! Jet grouting is excellent for stabilizing liquefiable soils and is particularly useful for underpinning foundations. It's important to keep in mind that its performance is closely tied to the strength of the grouted zone.

So, if the strength is low, the effectiveness might decrease?

Correct! A strong grouted zone can limit deformations effectively, especially during seismic events. As a final mnemonic, think 'Jet = Speed and Strength' to remember its rapid application and strength factors.

Summary of Grouting Techniques

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s summarize what we've learned about grouting techniques: 'CPJ' for Compaction, Permeation, and Jet grouting. Each serves a unique purpose in soil stabilization. Who can list some of the key differences?

Compaction grouting increases density, while permeation grouting focuses on stabilization without disrupting the structure!

And jet grouting is more aggressive, replacing soil with a stronger mix!

Excellent! Remember these distinctions and applications as they are crucial for understanding soil improvement. Keep your notes handy, and review them regularly!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section explores three primary grouting methods—compaction grouting, permeation grouting, and jet grouting—emphasizing their applications, processes, and effectiveness in improving soil's resistance to liquefaction.

Detailed

Detailed Summary

The section outlines several soil improvement techniques relevant to grouting, particularly suited for enhancing the stability of liquefiable ground. The techniques discussed include:

- Compaction Grouting: Involves injecting a stiff cement paste that compacts surrounding soil, effectively increasing its density. It is categorized based on its application under existing structures, in urban environments, and in constrained spaces.

- Permeation Grouting: This technique involves the injection of low-viscosity fluid into soil pores, enhancing its physical and mechanical properties while mitigating liquefaction risks, particularly in saturated and loose soils. It operates with minimal disruption, making it ideal for urban settings.

- Jet Grouting: This method utilizes high-pressure jets to inject a cement mixture into the ground, replacing existing soil with a stronger mixture. It's crucial for underpinning foundations, stabilizing soft soils, and controlling groundwater.

Each technique is detailed with its operational principles, advantages, and case studies indicating their effectiveness, particularly in earthquake-prone regions.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Soil Improvement Techniques

Chapter 1 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The soil improvement techniques are effective for each of the allowed or required disturbance of existing structures. The following methods, which imply a low level of vibration, are useful to improve liquefiable ground by solidification: (a) Compacting grouting; (b) Permeation grouting; (c) Jet grouting;

Detailed Explanation

Soil improvement techniques play a crucial role in enhancing the stability and strength of soil, particularly in areas prone to liquefaction, which is when saturated soil substantially loses strength and stiffness due to applied stress. The main methods outlined are Compacting Grouting, Permeation Grouting, and Jet Grouting. These methods are specifically chosen for their ability to cause minimal disturbance and vibration, which is vital when working near existing structures.

Examples & Analogies

Imagine building a house on a sponge. When it rains, that sponge can become weak and unstable. Just like you would use a solid base to strengthen that sponge, soil improvement techniques help make the ground solid and reliable for structures on top.

Compaction Grouting Explained

Chapter 2 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Compaction grouting is a soil injection with low workability cement paste that remains homogeneous without entering in the soil pores. The cement mass extends, soil is moved and finally compacted. The liquefaction improvement using compaction grouting divides into the following categories: (a) Treatment under existing structures; (b) Treatment in urban areas with low levels of vibration and noise; (c) Treatment in narrow areas.

Detailed Explanation

Compaction grouting involves injecting a specially mixed cement paste into the soil. This cement paste does not penetrate the soil pores but works to push and compact the surrounding soil, increasing its density. There are three primary applications for this technique: reinforcing soil under existing buildings, providing treatment in urban environments to minimize noise and vibration, and applying the technique in tight or narrow spaces where larger equipment may not fit.

Examples & Analogies

Think of a balloon being stretched. When you blow air into it and it expands, the outside material stretches and becomes denser. In compaction grouting, the cement acts like the air, pushing the soil and making it denser and stronger.

Injection Process in Compaction Grouting

Chapter 3 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The execution of compaction by injection technology using bottom-up method takes place as follows. In the first stage, injection pipes set up on the foundation soil of the existing or future foundations using drilling machines. The injection process begins. Mixture injected through the pipes pushes the surrounding soil; then the injection pipes raises about 0.3-1.5 m and the process renews. The “in steps” injection process continues until the whole thickness of the soil layer is treated. Injection stabilizes soil layer by density and pressure increasing.

Detailed Explanation

Using the bottom-up method for compaction grouting, pipes are placed into the ground to inject the cement mixture. The process involves injecting these mixtures, which lift the injection pipes incrementally (between 0.3 to 1.5 meters), and this is repeated until the entire layer of soil is treated, enhancing its density and stability.

Examples & Analogies

Imagine watering a garden using a hose that has to be lifted every so often. Just as you move your hose systematically to ensure every part of the garden gets water, the injectors lift and move to make sure all soil receives the cement mix for solidification.

Effectiveness and Applications of Compaction Grouting

Chapter 4 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

The primary purpose of compaction grouting is to increase the density of soft, loose or disturbed soil, typically for settlement control, structural re-leveling, increasing the soil’s bearing capacity, and mitigation of liquefaction potential.

Detailed Explanation

The main goal of compaction grouting is to improve the properties of weak soils to prevent settlement issues, improve structural integrity, and increase load-bearing capacity. By compacting loose soil, the chances of liquefaction during seismic events are greatly reduced, providing a safer foundation for structures.

Examples & Analogies

Think of an old, crumbling road. If you fill in the cracks and densify the materials, the road will be safer and able to support more vehicles without sinking or cracking. Compaction grouting does the same for soil, ensuring it’s solid enough to support buildings.

Permeation Grouting and Its Purpose

Chapter 5 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Permeation grouting consists of the injection of a low-viscosity fluid in the soil pores without changes in the soil physical structure. The main goal of permeation grouting is both to strengthen soils through particle cementation (to stabilize the links between particles) and to waterproof ground by filling its pores with injected fluid.

Detailed Explanation

Permeation grouting involves injecting a fluid that can flow into the soil’s pores. This fluid helps bond the soil particles together, making the soil stronger. In addition, it fills spaces within the soil, improving its ability to resist water and reduce the risk of liquefaction, especially during earthquake events.

Examples & Analogies

Imagine a sponge soaked in water. When you inject a glue-like substance into the sponge, it becomes more solid and stable. Permeation grouting works similarly by solidifying the soil structure, allowing it to hold tight even under stress.

Quality Control in Permeation Grouting

Chapter 6 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Quality Control & Quality Assurance Like any other grouting improvement process, the quality control during permeation grouting is very important to ascertain the effectiveness of the technique.

Detailed Explanation

Ensuring quality control during permeation grouting is crucial. Factors like pressure and volumes of the injected grout are carefully monitored to prevent issues like soil fracturing or unintended expansion.

Examples & Analogies

Just as a baker closely measures ingredients to ensure a perfect cake, workers have to carefully control the grout mixture and injection process to achieve the desired soil improvement.

Jet Grouting Overview

Chapter 7 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

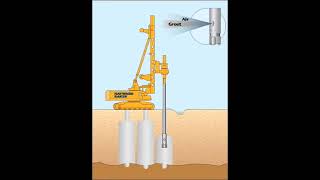

Applications of the jet grouting system fall into three broad categories: underpinning or excavation support, stabilization of soft or liquefiable soils, groundwater or pollution control.

Detailed Explanation

Jet grouting employs high-pressure injections of a mixture to replace existing soil with newly mixed materials, effectively stabilizing the ground. This method targets underpinning (supporting existing structures), enhancing the stability of weak soils, and controlling groundwater or environmental contaminants.

Examples & Analogies

Think of jet grouting like using a high-powered water jet to carve out and replace a blocked drainage pipe. The jet replaces old, unsteady soil with solid, supportive material, ensuring everything remains stable and secure.

Limitations and Considerations of Jet Grouting

Chapter 8 of 8

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Jet-grouted column spacing and diameters were selected on the basis of footing spacing, footing loads, floor slab loads, and judgment. A primary and secondary grid of columns was installed in a rectangular pattern to provide blanket treatment.

Detailed Explanation

For effective jet grouting, the spacing and size of the columns must be tailored to the specific loads and conditions of the site. A grid pattern of columns is often used to ensure thorough ground treatment, which is essential for both load-bearing support and liquefaction mitigation.

Examples & Analogies

It’s like laying out a chessboard where every piece is placed strategically to control the board. Similarly, engineers must carefully plan where each jet column goes to maximize support and stability.

Key Concepts

-

Liquefaction: A major concern in geotechnical engineering, where saturated soils lose stability under stress, especially during earthquakes.

-

Compaction Grouting: A technique aimed at increasing soil density by injecting a stiff grout mixture.

-

Permeation Grouting: Involves filling soil pore spaces with low-viscosity grouts to enhance stability minimally disruptively.

-

Jet Grouting: A robust method that uses high-pressure injection to enhance soil properties and groundwater management.

Examples & Applications

An airport runway where compaction grouting improved the soil density under existing structures.

A case study showcasing permeation grouting utilized in urban settings to control groundwater migration.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Grouting stout, compact and proud, fills the ground, a solid crowd.

Stories

In a bustling city, a builder faced soft soils threatening a foundation. Compaction grouting came to the rescue, injecting stiff grouts that firmed up the ground beneath, securing the buildings above.

Memory Tools

Remember 'CPJ' for Compaction, Permeation, and Jet grouting—that's the trio of grouting methods!

Acronyms

Use 'GROW' to remember Grouting Remediation of Our Wetlands, where grouting improves liquefaction risk.

Flash Cards

Glossary

- Compaction Grouting

A method of soil improvement involving injection of a stiff grout to increase soil density and mitigate liquefaction risk.

- Permeation Grouting

A technique that uses low-viscosity fluids to fill soil pores without changing physical soil structure, improving stability and preventing liquefaction.

- Jet Grouting

A ground improvement technique that injects a cement mixture under high pressure to replace existing soil, enhancing strength and stability.

- Liquefaction

The process by which saturated soil substantially loses strength and stiffness in response to applied stress, often leading to ground failure.

Reference links

Supplementary resources to enhance your learning experience.