Integration Challenges and Solutions

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Power Conflicts

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're discussing a common challenge in system integration: power conflicts. Can anyone tell me what might happen if we have power sequencing issues?

We might damage some components if the power is applied in the wrong order.

Exactly! Power sequencing is crucial. To mitigate these issues, we can validate power sequencing and check current loads along with regulator specifications. Let's remember the acronym 'PSC' for Power Sequencing Check!

So, 'P' for Power, 'S' for Sequencing, and 'C' for Check?

Right! Great job! Understanding this can save us from costly integration mistakes.

To summarize, ensuring correct power sequencing not only protects our components but also enhances overall system reliability.

Signal Timing Mismatch

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let's discuss timing mismatches. Can anyone guess why they might be an issue?

If the signals don’t sync up, we could lose data or create errors.

Precisely! One solution is to employ proper clock domains or use buffers for timing adjustments. Who remembers how we can synchronize signals effectively?

We can use buffers and possibly re-timing techniques?

Great! Remember the mnemonic 'TSR': Timing Synchronization Remedies! This will help you recall the methods to adjust timing issues.

In summary, effective timing management is essential for reliable system operation.

Communication Errors

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's explore communication errors. What issues do you associate with them?

Oh, like when two devices can’t communicate well due to mismatched protocols.

Exactly! Tools like logic analyzers are essential here for diagnosing issues. Who can tell me one way to troubleshoot communication?

We can monitor the signal lines to see where errors occur!

Exactly right! We’ll use 'CMT' – Communication Maintenance Tools! Remember this acronym.

In summary, recognizing and correcting communication errors early on is key to successful integration.

Mechanical Misalignment

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, we have mechanical misalignment. Why is this a big deal?

It can cause parts to not fit or work correctly, potentially malfunctioning.

Correct! To mitigate this, reviewing 3D CAD models and checking tolerances is crucial. Remember, 'CM' for CAD Model review!

That makes sense, solid planning can prevent misalignment.

Absolutely! Regular checks can save a lot of headaches later on. To sum up, mechanical alignment is essential for functional integration.

Incompatible Protocols

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Lastly, let’s talk about incompatible protocols. What comes to mind?

Different parts of the system might not communicate because they use different protocols.

Exactly! The use of protocol converters or firmware layers can help. Can anyone suggest a good mnemonic for this?

How about 'P-CFL'? Protocol Converter Firmware Layers?

Brilliant! Remember that 'P-CFL' can ensure your components talk to each other effectively.

To conclude, addressing protocol compatibility is crucial for successful integration. Now, let’s recap all the challenges we discussed today!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Integration of hardware components often faces challenges such as power conflicts, timing mismatches, communication errors, mechanical misalignments, and incompatible protocols. This section outlines effective mitigation strategies for each challenge, emphasizing the importance of thorough validation and testing protocols.

Detailed

Integration Challenges and Solutions

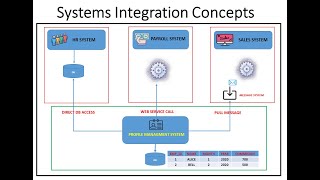

The integration of systems, particularly in hardware engineering, often leads to various challenges that can hinder performance and system functionality. Understanding these challenges and implementing effective mitigation strategies is crucial for successful integration.

Key Integration Challenges and Solutions

- Power Conflicts: Power sequencing issues can lead to components receiving incorrect voltages or currents.

- Mitigation: Validate power sequencing and check current loads and regulator specifications before the integration process.

- Signal Timing Mismatch: Incorrect timing can cause data errors and system failures.

- Mitigation: Use proper clock domains, incorporate line buffers, or employ re-timing techniques to synchronize signals across components.

- Communication Errors: Inter-component communication may fail due to protocol mismatches or electrical noise.

- Mitigation: Use diagnostic tools such as logic analyzers and bus monitors to identify and resolve communication errors during the integration process.

- Mechanical Misalignment: Physical components may not align properly during integration, leading to functional failures.

- Mitigation: Review 3D CAD models and perform tolerance stack-ups to ensure physical compatibility before assembly.

- Incompatible Protocols: Certain subsystems may use protocols that do not match or interface correctly.

- Mitigation: Implement protocol converters or use firmware abstraction layers to help unify communication between different components.

Effective integration requires careful planning, testing, and validation to meet the overall functional and performance goals of the system.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Power Conflicts

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Validate power sequencing, current loads, regulator specs

Detailed Explanation

Power conflicts occur when components in a system require power to be turned on in a specific order or draw too much current at once. To prevent these issues, it's important to validate the power sequencing of each component, ensuring they turn on and off in the correct order. Additionally, check the current loads to make sure that no component causes the power supply to exceed its limits, and verify that voltage regulators meet the specs needed for all components.

Examples & Analogies

Think of a power conflict like a busy traffic intersection. If cars (power) are allowed to enter the intersection at the same time from all directions, it can lead to crashes (failures). Just like traffic lights control which cars go when, validating power sequencing helps ensure that each component gets the power it needs without overwhelming the system.

Signal Timing Mismatch

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Use proper clock domains, buffers, or re-timing

Detailed Explanation

Signal timing mismatch happens when different parts of a system operate at different speeds or they expect signals at different times. To address this issue, it’s advisable to implement proper clock domains, which synchronize operations. Buffers can also be used to adjust the timing of signals, ensuring they arrive at the correct time. Re-timing can further adjust signals so they fit within the expected timing intervals.

Examples & Analogies

Imagine a relay race where each runner must pass a baton. If one runner runs too fast or too slow, the baton might not be passed properly, causing delays or failures in the race. Similarly, in a system, using clocks and buffers ensures that signals are passed at the right time, maintaining smooth operation.

Communication Errors

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Use logic analyzers and bus monitors

Detailed Explanation

Communication errors can occur when systems or components fail to correctly send or receive data. To troubleshoot these issues, engineers can use logic analyzers, which capture and analyze digital signals to ensure that the communication lines are functioning correctly. Bus monitors can also help to observe how data travels across communication protocols like USB or I2C.

Examples & Analogies

Think of communication errors as misunderstandings in a conversation. If someone mishears a phrase or speaks too quietly, the message may not be transmitted correctly. Just as we might repeat a phrase to ensure it's understood, engineers use tools like logic analyzers to repeat and check communication signals.

Mechanical Misalignment

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Review 3D CAD models and tolerance stack-ups

Detailed Explanation

Mechanical misalignment occurs when physical components do not fit together as designed, leading to operational issues. To avoid this, engineers should review 3D CAD models to visualize and check how parts will interact. Tolerance stack-ups are also analyzed to determine if the manufacturing limits of each part may lead to misalignment.

Examples & Analogies

Consider assembling a piece of furniture with pre-drilled holes. If the holes are misaligned, the components won't fit together properly. In engineering, reviewing CAD models helps ensure everything fits as intended before assembly, just like checking the instructions and holes in furniture to ensure a good fit.

Incompatible Protocols

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Add protocol converters or firmware abstraction layers

Detailed Explanation

Incompatible protocols can create communication barriers between different components of a system, as each may use a different method for data transfer. To resolve this, engineers can incorporate protocol converters, which change one protocol into another, allowing different components to communicate. Additionally, firmware abstraction layers can help bridge the gaps by translating data formats and commands.

Examples & Analogies

Think of incompatible protocols like speaking different languages. If two people speak different languages, they wouldn't understand each other. A translator (protocol converter) helps them communicate, ensuring the messages get through accurately. Similarly, converters and abstraction layers help different hardware communicate effectively.

Key Concepts

-

Power Conflicts: Issues due to improper power sequencing and electric load mismatches.

-

Signal Timing Mismatch: Problems arising when signals arrive at different times.

-

Communication Errors: Failures in data messaging between components.

-

Mechanical Misalignment: Physical fitting issues between hardware elements.

-

Incompatible Protocols: The complexities arising when subsystems use different communication protocols.

Examples & Applications

An integration failure due to power conflicts might lead to a microcontroller failing to start, resulting in a system that cannot boot.

A signal timing mismatch may cause a timing circuit error, leading to incorrect data being processed or displayed.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

If power's not in line, it's a clear design crime. Fix the load to make it right, then integration shines bright!

Stories

Imagine two friends trying to talk on different phones. One will have to switch phones or use an adapter to ensure they can communicate, much like our systems needing to align protocols.

Memory Tools

Use the mnemonic 'C-PAM' for 'Clock, Power, Alignment, Misalignment' to remember core challenges.

Acronyms

Remember 'PCSMI'

Power Conflicts

Signal Mismatches

Communication Errors

Mechanical Issues.

Flash Cards

Glossary

- Power Conflicts

Issues that arise when different components require different power supplies or sequencing to function correctly.

- Signal Timing Mismatch

A situation where data signals do not synchronize properly, resulting in errors or data loss.

- Communication Errors

Failures in data transfer between components, often due to protocol mismatches or faulty hardware.

- Mechanical Misalignment

The incorrect alignment of physical components, which can lead to operational issues.

- Incompatible Protocols

Situations where different subsystems communicate using different protocols, preventing proper integration.

Reference links

Supplementary resources to enhance your learning experience.