Challenges and Considerations

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Packaging and Interconnect Issues

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, let's discuss one of the critical challenges in MEMS technology: packaging and interconnect issues. MEMS components are tiny yet require robust packaging to ensure their performance. Can anyone explain why packaging is so important for MEMS?

I think it's to protect the microscale components from damage and contamination, right?

Exactly! Packaging protects MEMS from physical damage and environmental factors. It also facilitates electrical connections. What do you think are some challenges in making these connections at such a small scale?

Maybe it's difficult to make the connections reliable without affecting the overall functionality?

Correct! Ensuring reliable interconnections without compromising functionality is a challenge. Remember the acronym PIEC: Packaging, Interconnect, Environment, and Complexity for MEMS considerations! Let's move to environmental sensitivity.

Sensitivity to Environmental Conditions

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's talk about sensitivity to environmental conditions. How do temperature and humidity affect MEMS?

I believe changes in temperature can cause materials to expand or contract, which might break the delicate structures.

That's right! Environmental changes can lead to misalignment or even failures in MEMS components. Student_4, can you think of any applications where this sensitivity might be especially critical?

In medical devices, right? If they don't work properly under different conditions, it could be really dangerous.

Good point, student_4! This is why understanding environmental sensitivity is crucial in MEMS design. Let’s move on to mechanical wear.

Mechanical Wear and Fatigue

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, we need to discuss mechanical wear and fatigue. Why do you think this is a concern in MEMS?

Because they have moving parts that can wear out over time?

Exactly! The tiny moving parts are at risk of failure due to wear and fatigue. Student_2, what might be done to mitigate these issues?

We could design more durable materials or perhaps reduce the friction in moving parts?

Great suggestions! Material choice and design modifications are essential strategies for enhancing durability. Remember to keep durability in mind when designing MEMS devices. Now onto manufacturing processes!

Complex Manufacturing Processes

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let's discuss the complexity of MEMS manufacturing processes. Why do you think precision is critical?

Because any mistake in the tiny sizes could ruin the entire device, right?

Exactly! Even a small error can be detrimental in MEMS fabrication. Student_4, what manufacturing techniques do you think are used to achieve such precision?

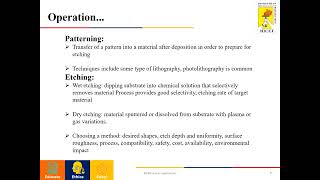

I guess techniques like photolithography are useful since it’s widely used in creating small structures.

Spot on! Photolithography is indeed one of the key techniques for MEMS. Let’s summarize today’s discussion to reinforce your understanding.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The challenges associated with MEMS technology encompass packaging and interconnection difficulties, susceptibility to environmental changes, concerns regarding mechanical durability, and the intricacy of manufacturing processes that demand high precision. Understanding these challenges is crucial for effective design and application.

Detailed

Challenges and Considerations in MEMS Technology

Despite the transformative benefits that Microelectromechanical Systems (MEMS) offer in various applications, several challenges impact their design and implementation. Firstly, packaging and interconnect issues at the microscale pose significant hurdles, as ensuring reliable connections and protection for delicate MEMS components is complex. Secondly, MEMS devices are increasingly sensitive to environmental conditions, such as fluctuations in temperature and humidity, which can adversely affect their performance and reliability. Thirdly, mechanical wear and fatigue in moving parts can lead to premature failure, thereby necessitating careful consideration during the design phase to ensure longevity. Lastly, the complex manufacturing processes required for MEMS necessitate high precision, making it both time-consuming and costly. Addressing these challenges is pivotal for advancing MEMS technology and enhancing their applicability across industries.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Packaging and Interconnect Issues

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Packaging and interconnect issues at the microscale

Detailed Explanation

At the microscale, the way components are packaged and interconnected is very challenging. Packaging involves enclosing the MEMS device to protect it, while interconnects refer to the connections between the MEMS device and the external circuitry. As devices shrink, traditional packaging techniques may no longer be suitable, leading to potential failures or inefficiencies.

Examples & Analogies

Imagine trying to fit multiple electronic components into a small box. If the box is too cramped, connections could become loose, leading to malfunction. This is similar to fitting tiny MEMS devices into packages designed for larger components.

Sensitivity to Environmental Conditions

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Sensitivity to environmental conditions such as temperature and humidity

Detailed Explanation

MEMS devices are often sensitive to changes in their environment, like temperature and humidity. Variations in temperature can lead to expansion or contraction of materials, affecting the device's performance. Moisture can also introduce issues such as corrosion. These sensitivities necessitate careful design and testing to ensure reliability across different environments.

Examples & Analogies

Think about a smartphone that sometimes doesn’t work properly in humid weather. Just as the phone may struggle, MEMS devices in similar conditions can experience performance issues because they are designed at a very small scale and can be affected easily by their surroundings.

Mechanical Wear and Fatigue

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Mechanical wear and fatigue in moving parts

Detailed Explanation

In MEMS, moving parts are crucial for functions like sensing or actuating. However, these parts are subject to mechanical wear over time. This means that as they move, they can gradually deteriorate, leading to performance declines. Engineers must consider this when designing MEMS to ensure a good lifespan and reliability.

Examples & Analogies

Consider the wheels of a bicycle. The more you ride, the more the wheels wear down. Similar to how the bicycle wheels might need replacing after a lot of use, MEMS devices also face wear and might need to be replaced or repaired as they age.

Complex Manufacturing Processes

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Complex manufacturing processes requiring high precision

Detailed Explanation

The fabrication processes for MEMS are complex and require high precision to ensure that the tiny components work correctly. Techniques such as photolithography and etching must be performed with extreme accuracy. Any minor errors can significantly impact the device's functionality, making the manufacturing process both challenging and costly.

Examples & Analogies

Creating a miniature sculpture might require precise carving. If the sculptor misjudges their cuts, the entire piece could be ruined. Similarly, if MEMS components are not manufactured correctly, their performance could be compromised, resulting in wasted resources and time.

Key Concepts

-

Packaging: The safeguard for MEMS against damage and contamination.

-

Interconnect: The connections that allow electrical flow within MEMS.

-

Environmental Sensitivity: The impact of external factors on MEMS performance.

-

Mechanical Wear: The deterioration of components due to usage.

-

Fatigue: The failure of materials from repeated stress.

-

Manufacturing Processes: The techniques used to fabricate MEMS.

Examples & Applications

An automotive MEMS accelerometer that must be reliably packaged to withstand crash conditions.

A biomedical sensor that is sensitive to humidity, requiring specialized protective coatings.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Tiny MEMS, so we must care, packaging them with utmost flair.

Stories

Imagine a fragile MEMS chip like a delicate flower, needing robust packaging to thrive amidst harsh conditions, just as flowers need protection from storms.

Memory Tools

To remember packaging considerations, use PIEC: Packaging, Interconnect, Environment, Complexity.

Acronyms

For MEMS challenges, think of PIEC – Precision in Interconnects and Environmental Considerations.

Flash Cards

Glossary

- Packaging

The method by which MEMS devices are secured and protected to safeguard their functionality.

- Interconnect

Electrical connections that link various components within a MEMS device.

- Environmental Sensitivity

The degree to which MEMS devices are affected by varying environmental conditions, such as temperature and humidity.

- Mechanical Wear

The gradual degradation of moving components due to friction and operation over time.

- Fatigue

The weakening of materials after repeated stress or strain, potentially leading to failure.

- Manufacturing Processes

Techniques utilized in the production of MEMS, involving high precision and specificity.

Reference links

Supplementary resources to enhance your learning experience.