Overview of MEMS

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to MEMS

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we'll discuss Microelectromechanical Systems, or MEMS. Can anyone tell me what they think MEMS devices are?

Are they very small devices that combine electronics and mechanics?

Exactly! MEMS are miniature devices capable of sensing, controlling, and acting at the microscale. They integrate mechanical elements and electronics, which is a game-changer in many fields.

What kinds of applications do they have?

Great question! MEMS are found in cars, smartphones, medical devices, and even aerospace applications. They are essential for creating advanced, compact systems.

How are they made?

MEMS are fabricated using techniques similar to those used in integrated circuit manufacturing, including photolithography and etching. This allows for the miniaturization and complexity of these systems.

So they are both tiny and powerful?

Exactly! Their small size does not limit their capabilities. They can act individually or in arrays to create larger macro effects.

In summary, MEMS devices are miniature, highly functional systems integrating microelectronics and micromechanics, fabricating through advanced semiconductor techniques.

Applications and Fabrication

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's talk about the applications of MEMS. Can anyone give me examples of where we might find them?

They are in smartphones, right? Like the accelerometers?

Yes! MEMS accelerometers help determine orientation and can even detect movements. This is crucial for many features on smartphones and tablets.

What about cars?

Good point! In automotive technology, MEMS are used for airbag deployment systems, stability control through gyroscopes, and tire pressure monitoring.

How do they make these tiny devices?

They use photolithography and other semiconductor fabrication techniques to build them layer by layer. These methods allow precision at the microscale.

So MEMS can do a lot, but they are made using complex methods?

Correct! The process can be intricate, but it’s crucial for creating the high-performance MEMS we rely on in technology today. Remember, MEMS integrate multiple functions into a single chip.

In conclusion, MEMS are critical in many emerging technologies, and understanding their fabrication techniques is key to advancing their use.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The Overview of MEMS explains how these miniature devices can sense, control, and actuate at the microscale, utilizing microelectronics and micromechanics. Their fabrication involves techniques from integrated circuit manufacturing, paving the way for advancements across various industries.

Detailed

Overview of MEMS

Microelectromechanical Systems (MEMS) are revolutionary miniature devices that have transformed the field of engineering. These systems are adept at sensing, controlling, and actuating on a microscale, which translates to significant effects on a macroscale. MEMS devices typically combine the principles of microelectronics and micromechanics, facilitating the integration of sensors and actuators within compact form factors. The fabrication of MEMS relies on techniques inherited from integrated circuit (IC) manufacturing such as photolithography, etching, deposition, and bonding processes. This allows for the creation of highly complex systems that are instrumental in numerous applications across multiple industries, including automotive, aerospace, medical devices, and consumer electronics.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Definition of MEMS

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

MEMS are miniature devices that can sense, control, and actuate on the microscale, and function individually or in arrays to generate effects on the macroscale.

Detailed Explanation

MEMS stands for Microelectromechanical Systems. These devices are very small and integrate components that can sense changes in the environment (sensors), perform actions based on those changes (actuators), or control other devices. Although they operate on a tiny scale, they can work together to produce significant effects in the larger world around them.

Examples & Analogies

Imagine a personal fitness tracker. The sensors in the tracker detect your movement (like a pedometer), while the actuators could vibrate to remind you to move after sitting too long. Alone, these sensors and actuators make small changes, but together, they help you stay healthier.

Integration of microelectronics and micromechanics

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

These systems typically combine microelectronics with micromechanics, making it possible to integrate sensors and actuators into compact form factors.

Detailed Explanation

In MEMS technology, microelectronics (which deal with the electrical aspects) are combined with micromechanics (which deal with the mechanical aspects). This combination allows for the creation of devices that are very small but still very powerful because they can both sense their environment and react to it in real-time. The compact form factor makes them ideal for modern applications where space is limited.

Examples & Analogies

Think about a small remote-controlled car. It has a tiny battery (microelectronics) that powers its motor and sensors that detect obstacles (micromechanics). The integration of these parts into a single unit makes the car operate effectively in a small size.

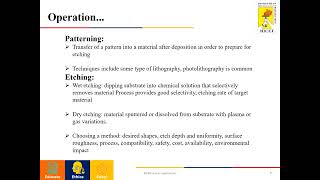

Fabrication Techniques of MEMS

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

MEMS devices are fabricated using techniques derived from integrated circuit (IC) manufacturing, including photolithography, etching, deposition, and bonding processes.

Detailed Explanation

The fabrication of MEMS devices involves advanced manufacturing techniques that were originally developed for creating integrated circuits (ICs). Photolithography allows for precise patterning of materials, etching removes unwanted material to shape the devices, deposition applies thin layers of materials, and bonding connects different layers together into a functional device. These processes ensure that MEMS devices are made with high precision and are reliable.

Examples & Analogies

Imagine baking a cake where you carefully layer different flavors and textures. Each layer represents a different fabrication process, such as deposition and bonding, coming together to create a delicious and cohesive cake, just like MEMS components are layered and combined to work together effectively.

Key Concepts

-

MEMS: Miniature devices that integrate sensing and actuation functions.

-

Integration: COMBINES microelectronics with micromechanics.

-

Fabrication: Utilizes semiconductor processing techniques.

Examples & Applications

MEMS accelerometers provide orientation data for smartphones.

Pressure sensors in MEMS monitor tire safety in automotive applications.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In tiny devices, sensors combine, MEMS are small, yet powerful by design.

Stories

Once upon a time, tiny machines named MEMS lived in smartphones and cars, working silently to help us control our world with precision.

Memory Tools

Microscopic Electronics Meet Sensors (MEMS).

Acronyms

MEMS

Miniature Electronics

Mechanical Systems.

Flash Cards

Glossary

- MEMS

Microelectromechanical Systems; miniature devices that combine mechanical and electronic elements.

- Micromechanics

The study of mechanical systems at the microscopic scale.

- Microelectronics

The use of extremely small electronic components, typically found in MEMS devices.

- Photolithography

A process used in microfabrication to pattern parts of a thin film.

Reference links

Supplementary resources to enhance your learning experience.