Key Components and Technologies in MEMS

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Sensors in MEMS

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're focusing on the first key component in MEMS: sensors. Can anyone tell me what a sensor does?

Isn't it something that detects certain variables like temperature or pressure?

Exactly! Sensors are devices that detect physical, chemical, or biological parameters. They are crucial in making MEMS functional. For example, you have pressure sensors in cars that help monitor tire pressure.

So, how about in phones? Do they use sensors as well?

Yes, they do! Smartphones use MEMS accelerometers and gyroscopes, which help in detecting motion and orientation. Remember the acronym *S.A.P.*? It stands for Sensors, Actuators, and Processors, which highlights key elements in MEMS.

How exactly do these sensors work?

Great question! Sensors convert detected changes in the environment into signals that can be processed, allowing for real-time monitoring. For example, a temperature sensor will change its resistance based on temperature variations.

Can you give an example of where this is applied?

Absolutely! In wearables, temperature sensors track body temperature, providing useful data for health monitoring.

To summarize, sensors are vital for enabling MEMS to interact with their environments and gather essential data, supporting various technologies across industries.

Actuators in MEMS

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let’s talk about actuators. Who can tell me what they do in a MEMS device?

Aren't they the parts that make something move or function?

Exactly! Actuators are components that produce motion or force. For example, microvalves are used to control the flow of fluids precisely.

What are some other examples of actuators?

Good question! We also have microgrippers, which can manipulate very small objects, and optical switches used in communication technologies. An easy way to remember this is with the acronym *M.O.F*: Microvalves, Optical switches, and Force generators.

Why are these actuators so crucial?

Actuators enable MEMS devices to perform tasks, bridging the gap between sensing and action. For instance, in automotive applications, MEMS gyroscopes help stabilize vehicles by adjusting controls based on sensor feedback.

How small can these actuators be?

They can be incredibly small, often just millimeters or micrometers in size, allowing for intricate designs and applications even in tiny spaces.

In summary, actuators are essential for converting signals into physical actions, enabling the functionality of MEMS across various platforms.

Microstructures in MEMS

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's move on to microstructures. What do you think they refer to in MEMS?

I think they are the very small mechanical parts, like tiny gears and levers?

You are correct! Microstructures include tiny mechanical components like beams, diaphragms, gears, and cantilevers. They serve as the building blocks for MEMS devices.

Can you explain a bit about how they function?

Certainly! Microstructures provide mechanical strength and facilitate operations at the microscale. For instance, a cantilever can bend when a force is applied, making it useful in sensors that detect mechanical stress.

What is the benefit of using such small structures?

Using small structures allows for more compact device designs, minimizing space and enhancing the integration of multiple functionalities. Remember the mnemonic 'Small Structures, Smart Systems!'

What are some practical applications of these microstructures?

Microstructures are found in myriad applications, from automotive sensors to medical devices ensuring precision and reliability due to their lightweight design.

To summarize, microstructures are key components that enable MEMS to perform diverse and intricate functions within compact designs.

Electronics Integration in MEMS

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let's examine electronics integration in MEMS. What do you think that means?

Does it mean putting electronic parts together with mechanical ones?

Correct! Electronics integration involves combining signal processing and control circuits directly on-chip with mechanical elements. This integration is crucial for creating complete microsystems.

What are some benefits of this integration?

The main benefit is enhanced performance efficiency. By integrating these components, it reduces the time and complexity of processing signals. For example, a MEMS microphone has built-in preamplifiers that provide better audio quality.

What about the challenges? Are there any?

Absolutely, the integration of electronics and mechanics can bring challenges such as the need for precise alignment and considerations of thermal management. However, overcoming these hurdles has led to significant innovations in SMART technology.

Can you give an example of where electronics integration has improved performance?

Sure! In automotive MEMS sensors, the seamless integration allows for quick processing of data, leading to faster deployments of safety features like airbag deployment during an accident.

In summary, the integration of electronics within MEMS devices significantly enhances their capabilities, enabling more intelligent and responsive applications in various industries.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The segment delves into the essential components and technologies involved in MEMS, emphasizing their roles and significance in creating functional microsystems. Key elements discussed include sensors for detecting parameters, actuators for producing motion, microstructures, and the integration of electronics, which together enable advanced applications across diverse industries.

Detailed

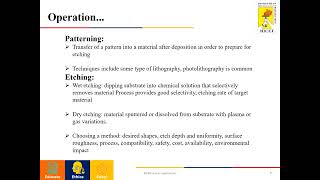

Key Components and Technologies in MEMS

MEMS, or Microelectromechanical Systems, involve multiple components essential for their functionality. This section explores four primary components:

- Sensors: These devices are crucial for detecting various physical, chemical, or biological parameters. They perform functions such as measuring pressure, acceleration, and temperature — integral to the operations of MEMS in various applications, ranging from consumer electronics to automotive systems.

- Actuators: Actuators are responsible for producing motion or force within MEMS. Examples of actuators include microvalves, which control fluid flow, microgrippers for manipulating small objects, and optical switches used in telecommunications. These elements enable MEMS to interact dynamically with their environments.

- Microstructures: This term refers to the miniature mechanical components, including beams, diaphragms, gears, and cantilevers. These microstructures form the backbone of MEMS devices, providing mechanical strength and facilitating various functionalities at the microscale.

- Electronics Integration: A critical technological advancement in MEMS is the integration of signal processing and control circuits directly on-chip with mechanical elements, creating a comprehensive microsystem that enhances performance efficiency.

Together, these components illustrate the synergy between mechanical and electronic engineering in MEMS, paving the way for innovative applications in diverse fields.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Sensors

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Sensors: Devices that detect physical, chemical, or biological parameters such as pressure, acceleration, temperature, or chemical composition.

Detailed Explanation

Sensors are crucial components of MEMS that allow these devices to interact with their environment. They function by detecting various parameters, which can include everything from pressure changes in a tire to temperature fluctuations in a room. Sensors convert physical changes into signals that can be measured and analyzed.

Examples & Analogies

Think of a sensor as the 'nervous system' of a MEMS device. Just like how our nervous system detects temperature, pressure, and other sensations in our body, MEMS sensors pick up similar environmental changes, allowing the larger system to respond accordingly.

Actuators

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Actuators: Components that produce motion or force. Examples include microvalves, microgrippers, and optical switches.

Detailed Explanation

Actuators are the moving parts of MEMS that perform actions based on the information received from sensors. They convert electrical energy into mechanical energy to create movement or apply force. For example, a microvalve can control the flow of fluids in a system, while microgrippers can pick up small objects.

Examples & Analogies

Imagine a robot hand that needs to grasp objects. The actuators work like the muscles in our arm, allowing the robot to 'grip' by opening and closing its fingers in response to signals from the sensors—just as our brain tells our muscles to move.

Microstructures

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Microstructures: Tiny mechanical components like beams, diaphragms, gears, and cantilevers.

Detailed Explanation

Microstructures are the small physical components that make up MEMS devices. They are engineered at the microscale and include elements like beams, which can bend or flex, and diaphragms, which can respond to pressure changes. These structures are designed to be lightweight yet strong enough to perform specific functions.

Examples & Analogies

Think of microstructures as the building blocks of a miniature amusement park. Each tiny structure, like a beam or gear, functions together to support rides (or in this case, the overall operation of a MEMS device), allowing it to function efficiently on a very small scale.

Electronics Integration

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Electronics Integration: Signal processing and control circuits are often integrated directly on-chip with mechanical elements to create a complete microsystem.

Detailed Explanation

Electronics integration refers to the merging of electronic components with mechanical structures on a single chip. This integration allows MEMS devices to not only sense and act but also process signals and control actions autonomously. It simplifies the design and enhances the connectivity between parts.

Examples & Analogies

Imagine a smartphone, which combines a camera, microphone, and speakers all in one device. Similarly, MEMS devices integrate sensors, actuators, and electronics to work seamlessly together, just like how different functions in your smartphone communicate to provide a smooth user experience.

Key Concepts

-

Sensors: Devices that detect parameters like pressure or temperature.

-

Actuators: Components that create motion in response to signals.

-

Microstructures: Mechanical parts allowing MEMS functionalities.

-

Electronics Integration: Combining electronic and mechanical components into a single system.

Examples & Applications

Pressure sensors in tire monitoring systems for automobiles.

MEMS microphones in smartphones that enhance sound clarity.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Sensors detect what’s near, actuators give a cheer!

Stories

Imagine a tiny robot that uses sensors to feel its way around. It has arms with actuators that help it reach and grab, showing how MEMS blends movement with sensing.

Memory Tools

Remember SAME - Sensors, Actuators, Microstructures, Electronics Integration - the essential components of MEMS.

Acronyms

Create your acronym *S.M.E.A.*

Sensors

Microstructures

Electronics

Actuators.

Flash Cards

Glossary

- Sensors

Devices that detect physical, chemical, or biological parameters such as pressure, acceleration, temperature, or chemical composition.

- Actuators

Components that produce motion or force in MEMS devices.

- Microstructures

Tiny mechanical components within MEMS that include beams, diaphragms, gears, and cantilevers.

- Electronics Integration

The process of combining signal processing and control circuits directly on-chip with mechanical elements in MEMS.

Reference links

Supplementary resources to enhance your learning experience.