Introduction to MEMS and Its Applications

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to MEMS

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Welcome to our class! Today we'll start with Microelectromechanical Systems, better known as MEMS. Can anyone tell me what MEMS stands for?

Microelectromechanical Systems!

That's correct! MEMS represent the integration of mechanical and electronic components on a small scale. They have transformed various industries by combining sensing and actuation capabilities. Let's begin with their core functionalities. MEMS can sense, control, or actuate, impacting larger systems. Can anyone think of an application using MEMS?

Maybe in smartphones? I hear they have accelerometers.

Exactly! MEMS accelerometers help detect orientation and motion in smartphones. Remember, the acronym 'SCA' stands for 'Sensing, Controlling, and Actuating'—it captures the essence of MEMS functions.

Can MEMS work outside electronics, like in cars?

Absolutely! They help with systems like airbag deployment. Let's recap what we've covered. MEMS integrate different functionalities and impact various sectors like consumer electronics, automotive, and biomedical. Anyone have questions before we move on?

Key Components of MEMS

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now that we understand the basics of MEMS, let’s discuss the key components. There are sensors, actuators, and microstructures. Can someone explain the role of sensors?

Sensors detect different conditions, right? Like temperature and pressure?

Correct! Sensors help gather data from the environment. As a mnemonic, remember 'SPL' for 'Sensors, Precision, and Layer'. Now, what about actuators?

Actuators produce movement or forces—like tiny motors, right?

Well said! They convert electrical energy into physical motion. So, how do microstructures fit in?

I think they form the mechanical components like gears and levers.

Exactly! These components work together to create the MEMS systems we use today. Let's summarize what we’ve learned about sensor roles and actuator functions.

MEMS Fabrication Techniques

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let’s explore how these MEMS devices are fabricated. There are various techniques like bulk micromachining and surface micromachining. Who can explain what bulk micromachining involves?

It removes material from the silicon to create structures?

Perfect! It's all about carving out the desired features. Now, surface micromachining builds structures in layers. Think of it like adding layers to a cake! Can anyone recall another fabrication method?

There's LIGA, which uses X-ray lithography!

Exactly right! LIGA stands for Lithographie, Galvanoformung, Abformung, and is great for creating high-aspect-ratio structures. Let’s recap the key fabrication techniques. Can anyone summarize?

There are bulk and surface micromachining and LIGA, each used differently for different structures.

Applications of MEMS

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s examine the wide range of applications MEMS have across various industries—from automotive to biomedical. What are some specific examples within those fields?

MEMS in cars help monitor tire pressure!

Correct! They also assist in airbag systems. What about consumer electronics?

Smartphones use MEMS for sensors and gyroscopes!

Right again! MEMS play a critical role in how these devices function. Remember the acronym 'CABI,' which stands for Consumer, Automotive, Biomedical, and Industrial applications. Can anyone name a biomedical use of MEMS?

Biosensors for diagnostics, like tracking glucose!

Exactly! This technology drives innovation in health monitoring. Let's summarize the impact of MEMS across different sectors.

Challenges and Trends in MEMS

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

As we wrap up our discussion on MEMS, it’s essential to address some challenges that come with this technology, like packaging issues and environmental sensitivity. Can anyone provide examples of these challenges?

Yeah, like how they can be affected by temperature changes?

Correct! Mechanical wear is also a concern. Let’s segue into current trends. Has anyone heard about integrating AI with MEMS?

Yes, I saw that they’re making smart sensors!

Absolutely! These are capable of processing data at the edge. To wrap up, remember that addressing challenges and adopting trends is crucial for MEMS' future. What are the main takeaways from today’s class?

MEMS have diverse applications! They integrate mechanics with electronics.

And they face challenges but are adapting with technologies like AI!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section delves into the fundamentals of MEMS, explaining how these miniature devices integrate mechanical and electronic components through advanced fabrication techniques. It also highlights the diverse applications of MEMS in fields such as automotive, biomedical, and consumer electronics, as well as the challenges faced in their implementation.

Detailed

Detailed Summary of Introduction to MEMS and Its Applications

Microelectromechanical Systems (MEMS) signify a revolutionary fusion of mechanical elements, sensors, actuators, and electronics onto a silicon substrate, achieved through microfabrication techniques. This chapter serves as a foundational overview, illustrating how MEMS contribute to the miniaturization and intelligent functionality of devices across multiple industries.

Overview of MEMS

MEMS are small-scale devices capable of sensing, controlling, and actuating actions at the microscale, with applications on the macroscale. By combining micromechanics with microelectronics, these systems are designed to work efficiently in compact spaces.

Key Components and Technologies

The components integral to MEMS include:

- Sensors: Detect parameters like pressure and acceleration.

- Actuators: Create motion or force, such as microvalves.

- Microstructures: Such as beams and gears that perform mechanical roles.

- Electronics Integration: Enabling on-chip signal processing.

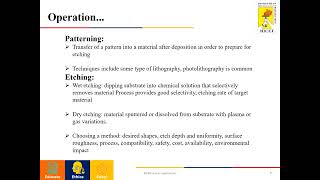

Fabrication Techniques

MEMS fabrication utilizes traditional semiconductor methods alongside specialized micromachining, including:

- Bulk Micromachining: To carve mechanical structures.

- Surface Micromachining: For layer-based microstructure construction.

- LIGA: A high-precision technique using X-ray lithography.

- Wafer Bonding: This technique effectively stacks and seals MEMS structures.

Applications of MEMS

MEMS technology is employed in diverse sectors:

- Automotive: Used in accelerometers and gyroscopes for vehicle safety.

- Consumer Electronics: Found in smartphones and gaming devices.

- Biomedical: In diagnostic biosensors and drug delivery systems.

- Aerospace: Essential for inertial measurement units (IMUs).

- Industrial: In flow and pressure sensors for automation.

Advantages of MEMS Technology

MEMS technology offers notable advantages, such as:

- Miniaturization of systems.

- Reduced power requirements.

- Cost-effective production methods.

- Enhanced reliability and sensitivity.

- Function integration into a single chip.

Challenges and Considerations

Despite their advantages, MEMS face challenges related to:

- Packaging and interconnections at a microscale.

- Environmental sensitivity affecting performance.

- Mechanical wear during operation.

- Complex manufacturing demands precision.

Recent Trends in MEMS

Recent advancements in MEMS include:

- NEMS (Nanoelectromechanical Systems): Pushing boundaries to nanoscale.

- AI Integration: Creating smart sensors for enhanced data processing.

- Flexible MEMS: Wearable tech for health monitoring.

- Wireless MEMS: Supporting IoT applications.

Conclusion

Overall, this chapter emphasizes the pivotal role of MEMS in driving innovation across technology landscapes, indicating a strong trajectory toward increased integration and application in future developments.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

What are MEMS?

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

In this chapter, we introduce the field of Microelectromechanical Systems (MEMS), which represents the integration of mechanical elements, sensors, actuators, and electronics on a common silicon substrate through microfabrication technology.

Detailed Explanation

MEMS stands for Microelectromechanical Systems. It is a technology that combines mechanical and electronic elements at a very small scale (microscale) using a process known as microfabrication. This means that tiny machines can be created that have mechanical parts (like moving gears) alongside electronic components (like sensors and circuits) on a single piece of silicon. This integration allows for the development of compact devices that can perform various functions.

Examples & Analogies

Imagine a small robot that fits in the palm of your hand. In this robot, the arms (mechanical parts) can move, and at the same time, it has tiny cameras and microphones (electronic components) that allow it to see and hear. This is similar to how MEMS technology works by combining different systems into one small device.

Impact of MEMS in Industries

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

MEMS has revolutionized multiple industries by enabling the miniaturization and smart functionality of devices, bringing together the worlds of mechanical and electronic engineering at the microscale. The applications of MEMS range from automotive and aerospace to medical devices and consumer electronics, demonstrating its wide-scale impact.

Detailed Explanation

MEMS technology has changed many industries significantly by allowing devices to become smaller and smarter. For example, in the automotive industry, MEMS sensors are used to detect things like tire pressure and acceleration, which improves safety and performance. In medical devices, MEMS can create tiny, smart diagnostic tools that help monitor health. This versatility shows how MEMS is applied across various fields, merging mechanical and electronic operations.

Examples & Analogies

Think about how smartphones are now equipped with sensors that can detect motion and orientation. For instance, a gyroscope in the phone allows it to know if you turn it sideways. This is all made possible because of MEMS technology, which allows these sensors to be incredibly small, yet still effective, creating a more powerful tool in a compact format.

What Can MEMS Do?

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

MEMS are miniature devices that can sense, control, and actuate on the microscale, and function individually or in arrays to generate effects on the macroscale. These systems typically combine microelectronics with micromechanics, making it possible to integrate sensors and actuators into compact form factors.

Detailed Explanation

MEMS devices can sense changes in the environment, control systems, and create motion. They can work alone or in groups (arrays) to deliver results that affect larger systems. For instance, a MEMS sensor might detect pressure changes and then send signals to other devices to respond accordingly. This combination of sensing and actuation makes MEMS incredibly powerful in creating responsive technologies.

Examples & Analogies

Consider a smart weather station that uses MEMS sensors to detect temperature and humidity. It can act in real time, adjusting a heating system or sending alerts based on the data it gathers. Just like a personal assistant that monitors your needs and responds immediately, MEMS work to gather information and create actions based on that information.

Key Concepts

-

Integration of Functions: MEMS integrate sensing, controlling, and actuating functions on a single chip.

-

Applications Across Industries: MEMS have vast applications, including automotive, consumer electronics, and biomedical devices.

-

Challenges in MEMS: Key challenges include environmental sensitivity and mechanical wear that affect functionality.

Examples & Applications

MEMS gyroscopes in smartphones for orientation detection.

MEMS pressure sensors for tire monitoring in vehicles.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

If sensors detect, and actuators direct, MEMS does connect, technology's architect.

Stories

Imagine a tiny robot named MEMS who could sense the warmth of sunlight, open a small umbrella to keep you cool, and dance around to keep you entertained, combining all its skills in a miniature system.

Memory Tools

Remember 'SCA' (Sensing, Controlling, Actuating) to recall the core functions of MEMS.

Acronyms

CABIM stands for Consumer, Automotive, Biomedical, Industrial, and Medical, summarizing the broad applications of MEMS.

Flash Cards

Glossary

- MEMS (Microelectromechanical Systems)

Miniature devices that integrate mechanical elements, sensors, actuators, and electronics through microfabrication.

- Sensors

Devices that detect physical, chemical, or biological parameters such as pressure, acceleration, or temperature.

- Actuators

Components that produce motion or force in a MEMS device.

- Microstructures

Tiny mechanical components like beams and gears within MEMS devices.

- Bulk Micromachining

A fabrication technique that removes material from the silicon substrate to create mechanical structures.

- Surface Micromachining

A method of building microstructures layer by layer on a substrate surface.

- LIGA

A high-precision fabrication process using deep X-ray lithography.

- Wafer Bonding

A process used to stack and seal MEMS layers.

Reference links

Supplementary resources to enhance your learning experience.