Challenges in MEMS System Design

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Process Incompatibility

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's start with process incompatibility. Can anyone explain why MEMS processes might not always align with CMOS workflows?

I think it’s because they use different materials and techniques.

That's correct, Student_1! MEMS devices often require specific materials and fabrication methods that do not always match the processes used for CMOS integration. This can lead to significant challenges in designing efficient systems.

So, what can we do to overcome these incompatibilities?

Good question, Student_2! One approach is to develop flexible integration strategies that can accommodate the unique requirements of both MEMS and CMOS technologies. Keeping abreast of advancements in fabrication techniques can also help.

In summary, addressing process incompatibility is crucial for effective MEMS system design. It requires creativity and adaptability in engineering.

Environmental Sensitivity

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let’s discuss environmental sensitivity. Why do you think MEMS devices are particularly sensitive to their surroundings?

Because they are so small? Any slight change might affect them?

Exactly, Student_3! Their small size and intricate structures make them vulnerable to contamination and shocks. Can anyone think of how this might affect performance?

Maybe they could produce inaccurate readings if knocked or if dirt gets in?

Precisely! That’s why robust design practices and proper sealing methods are essential. Let’s remember that MEMS systems must be designed to minimize these environmental influences.

To recap, environmental sensitivity is a major challenge in MEMS design that requires careful consideration of materials and protective measures.

Packaging-Induced Stress

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s move on to packaging-induced stress. What do you think packaging can do to a MEMS device?

It might protect it, but it could also hurt its performance.

Right, Student_1! While packaging is essential for protection, it can introduce stress that negatively impacts calibration and stability. Can anyone propose what strategies could be employed to alleviate these issues?

Perhaps using flexible materials or designing packaging that can absorb shocks?

Great ideas, Student_2! Proper material choices and innovative design approaches can indeed help in managing packaging stress. Remember, effective packaging is a balancing act.

In summary, packaging plays a critical role in MEMS performance, and managing the associated stress is key to successful design.

Size vs. Function Trade-offs

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let’s talk about size versus function. Why is this trade-off significant in MEMS design?

Because making something smaller could reduce its capability or reliability?

Exactly, Student_3! Miniaturization is often desired for compact designs, but we must ensure that performance and reliability remain intact. What could be the implication of compromising on these aspects?

It could lead to devices failing or performing poorly in real applications.

That’s spot on! It’s crucial for engineers to find a balance and not sacrifice quality for size. Remember, functionality must always guide size reduction.

To summarize, addressing the size-function trade-offs is vital for developing effective MEMS devices.

Testing and Standardization

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let’s discuss testing and standardization challenges. Why do we face difficulties in testing MEMS devices?

I think it’s because there aren’t universal standards to follow?

That’s correct, Student_1! The lack of universal testing standards complicates the evaluation process. What might be some consequences of this?

It could lead to variability in performance evaluations, potentially causing flawed designs!

Absolutely! This inconsistency can increase costs and complicate system integration. Thus, it becomes essential to drive towards developing unified standards.

In summary, establishing testing protocols and standards is crucial for the successful development and deployment of MEMS systems.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Designing MEMS systems involves several challenges such as process incompatibility with CMOS workflows, environmental sensitivity leading to performance issues, and complications due to packaging stress. Additional challenges include the trade-offs between size and function, along with the complexities of testing and standardization, making MEMS systems intricate to develop and implement.

Detailed

Challenges in MEMS System Design

Designing and deploying MEMS-based systems presents various challenges that need to be addressed effectively to ensure reliable performance. The primary challenges include:

- Process Incompatibility: MEMS fabrication processes often do not align well with standard CMOS processes, which can complicate integration efforts.

- Environmental Sensitivity: MEMS devices are sensitive to environmental conditions such as temperature changes, contamination risks, and mechanical shocks, which can adversely affect their performance.

- Packaging-Induced Stress: The packaging process can induce stress in MEMS devices, impacting calibration and long-term stability.

- Size vs. Function Trade-offs: While miniaturization is a desired goal, it should not compromise the performance or reliability of the MEMS devices, presenting a challenging balancing act for designers.

- Testing and Standardization: The lack of universal standards for testing MEMS systems increases complexity and costs, creating inconsistencies in performance evaluation and quality assurance.

These challenges highlight the importance of a holistic and interdisciplinary design approach in MEMS system design to achieve robust, scalable, and efficient solutions.

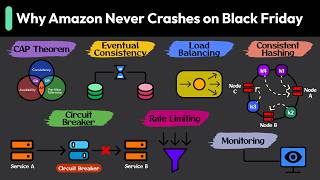

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Process Incompatibility

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

MEMS fabrication processes may not align with standard CMOS workflows.

Detailed Explanation

In MEMS system design, one of the significant challenges is that the process used to manufacture MEMS devices often does not mesh well with the processes used for standard CMOS (Complementary Metal-Oxide-Semiconductor) integrated circuits. This difference in fabrication can lead to complications in integrating both components on the same chip because they might require different materials, temperatures, or steps in manufacturing.

Examples & Analogies

Imagine trying to bake a cake using recipes that require two very different ovens: one that operates at a high temperature and needs a long time, and another that works at a low temperature and is quick. You must find a way to bake both correctly without compromising the taste or texture of the cake, just like engineers try to reconcile the different requirements of MEMS and CMOS.

Environmental Sensitivity

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

MEMS are prone to contamination, temperature changes, and mechanical shocks.

Detailed Explanation

MEMS devices are highly sensitive to their surroundings. They can easily be affected by contaminants in the air, such as dust or chemicals, which can alter their performance. Furthermore, temperature fluctuations can affect their operation since materials may expand or contract with heat, leading to inaccuracies. Mechanical shocks, like dropping the device, can also damage them or change their calibration.

Examples & Analogies

Think of MEMS devices like delicate glass ornaments. Just as these ornaments can get dusty, break from a fall, or become warped if left in extreme heat, MEMS devices need to be protected from environmental factors to maintain their functionality and integrity.

Packaging-Induced Stress

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Can affect calibration and long-term stability.

Detailed Explanation

Packaging is crucial for protecting MEMS devices, but if not done carefully, it can introduce stress that affects how well the device performs. This stress can alter the calibration of the devices, causing them to read incorrectly over time. Long-term stability can also be compromised, which may lead to failure of the device or inaccurate results.

Examples & Analogies

Imagine putting a tightly wrapped rubber band around a delicate flower. While the wrapping might keep it safe, if it's too tight, it could crush the petals and affect how the flower looks and grows. Similarly, if MEMS packaging is too constraining, it can impair the device's functionality.

Size vs. Function Trade-offs

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Miniaturization must not compromise performance or reliability.

Detailed Explanation

As engineers strive to make MEMS devices smaller, they encounter the challenge where reducing size can lead to a compromise in performance or reliability. A smaller device may not be able to handle certain operational requirements as well as a larger one, such as power output or signal clarity, which can degrade the overall functionality of the system.

Examples & Analogies

Consider a classic example of a small battery-operated flashlight. If you try to make it extremely small to fit in your pocket, you might have to use a weaker bulb that doesn’t provide enough light. Just like that flashlight, if MEMS devices are miniaturized without careful consideration, they might fail to perform their intended functions.

Testing and Standardization

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Lack of universal standards makes MEMS testing complex and costly.

Detailed Explanation

Unlike many electronic components that follow established testing standards, MEMS devices often face challenges due to a lack of universal testing protocols. This makes it complex to assess their performance accurately, leading to higher costs in development and quality assurance efforts since each MEMS may require customized testing procedures.

Examples & Analogies

Think about the difficulty of evaluating a unique dish when there are no standardized recipes to compare it with. Testing each dish's flavor, texture, and presentation can become tedious and expensive. Similarly, without standard protocols for MEMS testing, the process becomes cumbersome and costly for manufacturers and developers.

Key Concepts

-

Process Incompatibility: Issues arising from the mismatch between MEMS and CMOS fabrication methods.

-

Environmental Sensitivity: The tendency of MEMS devices to be affected by external conditions such as temperature and contamination.

-

Packaging-Induced Stress: Mechanical pressures created during packaging that can negatively impact device performance.

-

Size vs. Function Trade-offs: The need to balance compact design with performance and reliability.

-

Testing and Standardization: Challenges posed by the lack of universal standards leading to complexity and increased costs.

Examples & Applications

MEMS accelerometers in smartphones must be carefully designed to function reliably under varying temperatures and mechanical impacts.

The packaging of MEMS devices for automotive applications needs to withstand vibrations and shocks while ensuring long-term stability.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

MEMS are sensitive in the light, package them wrong and they won't be right.

Stories

Imagine a tiny MEMS device living in a world that's too hot or too cold. It struggles to stay stable in its little home and often gets too stressed when packaged incorrectly.

Memory Tools

Remember 'PESST': Process Incompatibility, Environmental Sensitivity, Stress from Packaging, Size vs. Function trade-offs, and Testing challenges.

Acronyms

MEMS - Miniaturized Electronics with Major Sensitivities.

Flash Cards

Glossary

- MEMS

Micro-Electro-Mechanical Systems, devices that combine mechanical and electrical components at microscale.

- CMOS

Complementary Metal-Oxide-Semiconductor, a technology used for constructing integrated circuits.

- Environmental Sensitivity

The vulnerability of MEMS devices to changes in temperature, contamination, and mechanical impact.

- PackagingInduced Stress

Mechanical stress introduced in MEMS devices during the packaging process that can affect performance.

- Tradeoff

A balance achieved between two conflicting features, such as size and functionality.

- Standardization

The process of developing and implementing technical standards to ensure compatibility and quality.

Reference links

Supplementary resources to enhance your learning experience.