Integration of MEMS Devices into Larger Systems

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Types of MEMS Integration

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will explore the types of MEMS integration. Can anyone tell me what monolithic integration is?

Isn't that where MEMS and electronics are made on the same chip?

Exactly, Student_1! Monolithic integration helps reduce size and improve signal integrity. However, it faces challenges like process compatibility. Now, can someone explain hybrid integration?

Hybrid integration means MEMS and electronics are made separately and then put together, right?

That's right! It offers more flexibility in optimization but needs precise alignment. Remember the acronym 'MHS' for Monolithic, Hybrid, System-in-Package, and 3D integration. Can anyone share what SiP means?

System-in-Package, where multiple components are combined into one module!

Correct! And lastly, what is unique about 3D integration?

It stacks layers using TSVs, allowing for compact systems!

Absolutely! To summarize, we discussed four types of MEMS integration: Monolithic, Hybrid, SiP, and 3D integration. Each has its pros and cons impacting their applications.

Examples of Integrated MEMS Systems

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Great job so far! Now, let's look at some real-world applications of integrated MEMS systems. Can anyone provide an example?

Smartphones uses MEMS accelerometers and gyroscopes, right?

Correct, Student_1! These devices help in orientation and motion sensing. What about automotive systems? Any thoughts?

They use MEMS sensors for airbag systems and stability control!

Exactly! Automotive applications showcase the reliability of MEMS. Now, who can tell me about MEMS in biomedical devices?

They are used in pressure sensors and microfluidic drug delivery systems!

That's great, Student_3! So, to recap, we've covered various MEMS applications in smartphones, automotive systems, and biomedical devices, highlighting the versatility of these technologies.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The integration of MEMS devices into larger systems encompasses various methods including monolithic, hybrid, system-in-package (SiP), and 3D integration. Each type has its advantages and challenges that influence design choices, impacting real-world applications in smartphones, automotive systems, and biomedical devices.

Detailed

Integration of MEMS Devices into Larger Systems

Successful integration of MEMS (MicroElectroMechanical Systems) devices requires combining various subsystems, including mechanical, electrical, thermal, and occasionally fluidic components onto a unified platform. The section covers the main types of MEMS integration:

1. Types of MEMS Integration

a) Monolithic Integration

- MEMS and electronics are fabricated on the same chip.

- Advantages: Reduced size, improved signal integrity, cost-effective for high-volume production.

- Challenges: Limited process compatibility between MEMS and CMOS technology.

b) Hybrid Integration

- MEMS and electronics are fabricated separately and then assembled.

- Advantages: Greater flexibility in process optimization for both MEMS and integrated circuits (ICs).

- Challenges: Requires precise alignment and bonding techniques.

c) System-in-Package (SiP)

- Packs multiple MEMS, ICs, and passive components together.

- Used in smartphones, wearables, and IoT devices, enhancing compactness and functionality.

d) 3D Integration

- Stacks multiple layers vertically using techniques like through-silicon vias (TSVs) or wafer bonding.

- Allows for compact, high-performance systems with a minimal footprint.

2. Examples of Integrated MEMS Systems

- Smartphones: Combine MEMS accelerometers, gyroscopes, and microphones with processors and wireless modules.

- Automotive Systems: Incorporate MEMS sensors in systems for airbags, tire pressure monitoring, and stability control.

- Biomedical Devices: Use integrated MEMS for implantable pressure sensors and microfluidic drug delivery systems.

This section emphasizes the multidisciplinary nature of MEMS integration as it necessitates coordination among mechanical, electrical, and software engineers, making it vital for effective system-level design.

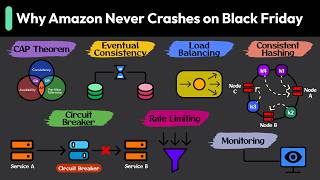

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Successful MEMS Integration Overview

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Successful MEMS integration involves combining mechanical, electrical, thermal, and sometimes fluidic subsystems in a unified platform.

Detailed Explanation

Successful integration of MEMS (Micro-Electro-Mechanical Systems) entails the cohesive combination of various types of subsystems. This means not just connecting electrical components, but also integrating mechanical parts that may move or sense changes, thermal components that manage heat, and in certain cases, fluidic systems which control or transport liquids. Creating this unified platform allows MEMS to function effectively within a larger system, such as a smartphone or an automotive application.

Examples & Analogies

Think of a MEMS device integration like a well-coordinated orchestra. Each musician represents a different subsystem—brass, strings, percussion, and woodwinds—all must work together in harmony to create beautiful music. If one section is out of sync or removed, the overall performance will suffer. Similarly, each MEMS subsystem contributes to the overall functionality and effectiveness of the system.

Types of MEMS Integration

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

9.2.1 Types of MEMS Integration

a) Monolithic Integration

- MEMS and electronics are fabricated on the same chip.

- Advantages: Reduced size, improved signal integrity, and cost-effective for high-volume production.

- Challenges: Limited process compatibility between MEMS and CMOS.

b) Hybrid Integration

- MEMS and electronics are fabricated separately and then assembled.

- Advantages: Greater flexibility in process optimization for both MEMS and ICs.

- Challenges: Requires precise alignment and bonding techniques.

c) System-in-Package (SiP)

- Multiple MEMS, ICs, and passive components are packaged together in a single module.

- Common in smartphones, wearables, and IoT devices.

d) 3D Integration

- Stacks multiple layers vertically using through-silicon vias (TSVs) or wafer bonding.

- Enables compact high-performance systems with minimal footprint.

Detailed Explanation

MEMS integration can be achieved through various types, including:

1. Monolithic Integration involves creating MEMS and electronic circuitry on a single chip, reducing size and costs while improving signal integrity. However, it faces compatibility issues between different processes.

2. Hybrid Integration allows MEMS devices and electronics to be created separately and then combined. This permits more flexibility in design but requires high precision in alignment and connections.

3. System-in-Package (SiP) involves integrating multiple MEMS, integrated circuits (ICs), and passive components into one package, which is especially utilized in consumer electronics like smartphones and wearables for space efficiency.

4. 3D Integration stacks components vertically by utilizing techniques like through-silicon vias, allowing even more compact systems without sacrificing performance.

Examples & Analogies

Imagine building a house. Monolithic Integration is like constructing both the foundation and the walls with a single material, ensuring everything fits perfectly but may limit design changes later. Hybrid Integration resembles constructing the foundation with bricks and the walls with wood; it offers flexibility but requires precision to connect them correctly. An SiP system is comparable to a modular house, where different sections like the kitchen and living area come together in one unit, making it easy to transport and install. Finally, 3D Integration is like stacking multiple floors in an apartment building; it maximizes the use of limited space while maintaining functionality in each layer.

Examples of Integrated MEMS Systems

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

9.2.2 Examples of Integrated MEMS Systems

- Smartphones: Combine MEMS accelerometers, gyroscopes, and microphones with processors and wireless modules.

- Automotive Systems: Airbag systems, tire pressure monitoring, and stability control systems rely on MEMS sensors integrated with control units.

- Biomedical Devices: Implantable pressure sensors and microfluidic drug delivery systems interface with data loggers and telemetry units.

Detailed Explanation

Integrated MEMS systems can be found in many everyday technologies:

- Smartphones: These devices utilize various MEMS components like accelerometers (for detecting motion), gyroscopes (for orientation), and microphones (for voice recognition), each working together with processors and wireless communication modules to enable a wide range of functions.

- Automotive Systems: Many modern cars use MEMS sensors in their airbag systems and tire pressure monitoring systems, where accurate data from these sensors informs the vehicle's control systems to enhance safety and performance.

- Biomedical Devices: MEMS technology plays a crucial role in healthcare with implantable sensors that monitor bodily functions, and microfluidic systems that help deliver medication in a controlled manner. These devices often integrate with data logging and telemetry systems for real-time health monitoring.

Examples & Analogies

Consider your smartphone as a Swiss Army knife. Just like each tool (blade, screwdriver, scissors) serves a different purpose yet fits together neatly in one compact device, MEMS components in a smartphone serve distinct functions (like motion sensing and audio capture) but are integrated into a single unit to maximize performance and efficiency. In the same way, automotive safety systems use various MEMS sensors as if they were multiple small assistants ensuring driver safety by constantly monitoring tire pressure and deploying airbags when necessary. Similarly, in healthcare, the integration of MEMS in devices is like having a personal health assistant that not only monitors your conditions but also delivers medication when needed.

Key Concepts

-

Monolithic Integration: Fabrication of MEMS and electronics on a single chip.

-

Hybrid Integration: Separate fabrication of MEMS and electronics with subsequent assembly.

-

System-in-Package: A module containing multiple MEMS and ICs.

-

3D Integration: Stacking of layers vertically to achieve compact designs.

Examples & Applications

Smartphones integrating accelerometers and gyroscopes for motion detection.

Automotive systems using MEMS in airbag deployment sensors.

Biomedical devices utilizing MEMS for drug delivery systems.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Monolithic's small, hybrid's flexible, SiP's all in one, 3D is stacked for compact fun!

Stories

Imagine a small factory where tiny robots (MEMS) are built together in one room (monolithic), while in another room, they are made separately and then joined using special tools (hybrid). Then, think of packages where many tiny robots are stored in a single box (SiP) or stacked for a taller design (3D).

Memory Tools

Remember the acronym 'MHS3' for Monolithic, Hybrid, System-in-Package, and 3D Integration.

Acronyms

MEMS

Miniature Electromechanical Systems.

Flash Cards

Glossary

- Monolithic Integration

Integration method where MEMS and electronics are fabricated on the same chip.

- Hybrid Integration

Integration where MEMS and electronics are fabricated separately and later assembled.

- SysteminPackage (SiP)

A method of packaging multiple MEMS, ICs, and passive components in a single module.

- 3D Integration

Integration technique that stacks multiple layers vertically utilizing through-silicon vias or wafer bonding.

- MEMS (MicroElectroMechanical Systems)

Miniature devices integrating mechanical and electrical components.

Reference links

Supplementary resources to enhance your learning experience.