Co-Design and Simulation Tools

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Importance of Co-Design

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will explore the significance of co-design in MEMS systems. Can anyone explain what co-design entails?

Isn't it when we design both mechanical and electronic parts together?

Exactly! Co-design merges the mechanical aspects of MEMS with their electronic counterparts. This synergy is essential for optimizing the system's overall performance. Think of it as teamwork for better outcomes!

What tools help in co-design?

Great question! We often use co-simulation environments like FEM tools and circuit simulators. This integration allows us to understand interactions and dependencies between different components.

How does this improve performance?

Good point! By working together, we can identify potential issues early on, leading to innovative interface designs and ultimately enhancing reliability and efficiency. Remember: TEAMwork leads to improved TECHnical solutions!

What's the benefit of virtual prototyping?

Virtual prototyping allows designers to test concepts quickly without physical models, reducing development time. It's like using a digital twin of your device!

To summarize, co-design is crucial for MEMS and electronics integration, and it leverages tools that can significantly enhance our design process and outcomes.

Simulation Tools

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's dig deeper into the types of simulation tools we use in MEMS design. Can someone name an example of a FEM tool?

COMSOL is one that I heard of!

Correct! COMSOL Multiphysics is a powerful FEM tool that allows for coupled simulations. This means we can model various physical phenomena and their interactions—important for MEMS!

What about circuit simulators?

Excellent! Circuit simulators like SPICE are pivotal for analyzing electrical circuits integrated with MEMS. They help us predict how these systems will behave under various conditions.

What role does behavioral modeling play?

Behavioral modeling, using tools like MATLAB/Simulink, is crucial for developing control algorithms and understanding system-level dynamics. It allows you to simulate how your MEMS will perform in real-world scenarios.

In summary, simulation tools like COMSOL and SPICE, alongside behavioral modeling, are integral to designing effective MEMS systems. They enable us to optimize performance before any physical prototypes are made.

Virtual Prototyping and Time-to-Market

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's discuss virtual prototyping. How do you think it impacts time-to-market for MEMS products?

It probably speeds up the process since you don’t need physical prototypes right away.

Correct! Virtual prototyping allows for earlier testing and iteration, which can shorten development timelines significantly.

Does it also reduce costs?

Absolutely! By minimizing the need for multiple physical prototypes, we can also cut down on material and labor costs. This process enhances overall efficiency.

Are there any downsides to virtual prototyping?

Good question! While virtual prototyping is beneficial, it is crucial to ensure that simulations are accurately calibrated to reflect real-world conditions. Otherwise, discrepancies can lead to issues post-manufacturing.

In conclusion, virtual prototyping is a powerful method that significantly enhances the design workflow for MEMS, improving both the speed and efficiency of bringing products to market.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

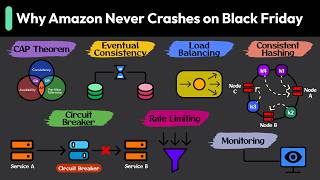

This section emphasizes the importance of co-design and simulation tools in MEMS system development. By utilizing co-simulation environments that integrate various modeling tools and virtual prototyping, designers can optimize MEMS structures alongside their electronics, resulting in improved system performance and reduced development time.

Detailed

Co-Design and Simulation Tools

Effective system design for MEMS devices necessitates collaborative simulation between MEMS structures and their accompanying electronic systems. This section discusses the importance of using co-simulation environments, which can incorporate Finite Element Method (FEM) tools such as COMSOL and circuit simulators like SPICE. These environments enable a cohesive analysis of mechanical and electrical interactions.

Behavioral modeling tools, such as MATLAB/Simulink, play a vital role in system-level modeling and the refinement of control logic. These tools allow for a comprehensive understanding of system dynamics, which is essential for developing complex applications.

Additionally, virtual prototyping is highlighted as a valuable practice in the design process. It significantly reduces time-to-market for MEMS products and increases the chances of achieving successful first-pass designs. Overall, the integration of these tools into the design workflow enhances the reliability and performance of MEMS systems in real-world applications.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Effective System Design

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Effective system design requires joint simulation of MEMS structures and surrounding electronics.

Detailed Explanation

This phrase emphasizes the importance of integrating various aspects of system design when working with MEMS (Micro-Electro-Mechanical Systems). Simply put, it means that to create a successful MEMS device, engineers cannot consider MEMS structures and electronic components as separate entities; they must look at how these parts will work together as a whole. This approach allows designers to predict how the MEMS device will perform in real-world situations and make necessary adjustments early in the design process.

Examples & Analogies

Imagine designing a new car. You wouldn't just focus on the engine separately without considering how it will interact with the wheels, chassis, and electronic systems like brakes and navigation. Just like that, in MEMS design, everything needs to work together smoothly.

Co-Simulation Environments

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Co-Simulation Environments: Combine FEM tools (e.g., COMSOL) with circuit simulators (e.g., SPICE).

Detailed Explanation

In this chunk, we learn about the tools that are used for co-simulation. FEM (Finite Element Method) tools, like COMSOL, are used to model physical phenomena in MEMS structures, while circuit simulators, like SPICE, are designed to simulate electronic circuits. By combining these tools in a co-simulation environment, engineers can analyze how the mechanical behaviors of MEMS devices interact with their electronic counterparts. This results in a more comprehensive understanding of potential performance issues and helps optimize the design before actual production.

Examples & Analogies

Think of co-simulation as a rehearsal for a theater play where actors (MEMS) and stage mechanics (the electronics) practice together. By running through their lines and cues together, they ensure that the final performance is smooth and flawless.

Behavioral Modeling

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Behavioral Modeling: Tools like MATLAB/Simulink allow system-level modeling and control logic development.

Detailed Explanation

Behavioral modeling involves creating a simplified representation of a system's behavior using tools like MATLAB/Simulink. This technique helps engineers design and test the control logic that will manage the interactions between the MEMS device and the electronic systems. In essence, behavioral modeling allows for the simulation of system operation under various conditions without needing the actual hardware, making it easier to refine designs and predict system performance in real-world scenarios.

Examples & Analogies

Imagine programming a sophisticated robot to perform tasks. Before building the actual robot, you might create a software model to test how it responds to different inputs. This approach ensures you get the desired outcomes before investing time and resources into the physical version.

Virtual Prototyping

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Virtual Prototyping: Reduces time-to-market and improves first-pass success.

Detailed Explanation

Virtual prototyping refers to the process of creating a digital version of a product to test and refine its design before actual manufacturing. By simulating the MEMS device in a virtual environment, engineers can identify potential issues and make improvements without incurring the costs associated with physical prototypes. This approach not only speeds up the overall design process—enabling faster delivery to the market—but also enhances the likelihood that the first version of the product will meet performance expectations without extensive revisions.

Examples & Analogies

Think of virtual prototyping like drafting a blueprint for a house. Before you start building, you create detailed plans to visualize the layout, materials, and design choices. This way, you can catch errors early on, ensuring that the house is constructed efficiently and correctly.

Key Concepts

-

Co-design: The integration of mechanical and electronic design processes.

-

Co-simulation: Simultaneous use of different simulation tools to evaluate system interactions.

-

FEM Tools: Software used for modeling material behavior under various conditions.

-

Behavioral Modeling: Conceptual representation of systems for analysis and control.

-

Virtual Prototyping: Digital creation of product models for testing and validation.

Examples & Applications

Using MATLAB/Simulink for developing control algorithms for MEMS devices.

Employing COMSOL for simulating thermal and structural analysis of MEMS components.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In co-design, we merge and align, MEMS and circuits make systems shine.

Stories

Imagine an engineer who needs to create a new MEMS device. She starts by sketching the interactions between the mechanical structure and the electronics, ensuring each part complements the other. By using co-simulation tools, she finds issues early and optimizes her design, leading to a successful product.

Memory Tools

Remember 'CFV' for co-design: 'C' for Co-simulation, 'F' for FEM, and 'V' for Virtual prototyping.

Acronyms

Use the acronym 'BASIC' for the key benefits of co-design

'B' for Better performance

'A' for Accuracy

'S' for Speed

'I' for Integration

and 'C' for Cost-effectiveness.

Flash Cards

Glossary

- Codesign

A collaborative design process for mechanical and electronic components in a MEMS system.

- Cosimulation

The simultaneous simulation of MEMS structures and electronics using integrated design tools.

- FEM (Finite Element Method)

A numerical technique for finding approximate solutions to boundary value problems for partial differential equations.

- Behavioral modeling

A method used to model the behavior of complex systems using simplified representations.

- Virtual prototyping

The creation of computer models to simulate the behavior of a product before it is physically built, enabling design testing.

Reference links

Supplementary resources to enhance your learning experience.