System-Level Design Considerations

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Electrical Interface and Signal Conditioning

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're diving into how MEMS devices communicate! Who can tell me what challenges we might encounter with signals from a MEMS device?

I think they can be weak or noisy.

Exactly! That's where signal conditioning comes into play. We use amplifiers and filters. Does anyone know what these do?

Amplifiers make the signals stronger, right?

That's correct! And filters help eliminate unwanted noise. Now, why do we need Analog-to-Digital Converters, or ADCs?

To convert the analog signals into digital data for processing!

Precisely! And in addition to these, feedback control plays an important role in systems using resonant sensors. Can someone remind me of what feedback control does?

It adjusts the output based on the input to keep the system stable!

Great understanding! To sum it up, effective electrical interfaces enhance MEMS performance by conditioning signals for better data processing.

Power Management

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next up, let's talk about power management. Why do you think power management is vital for MEMS devices?

Because they need stable and sometimes high voltage for some functions?

Exactly! Different designs might need different voltages. How about energy harvesting? What might that look like?

It’s when MEMS devices can generate power on their own, especially in remote locations.

Right! This is particularly useful in wearable tech. Any examples of MEMS that might benefit from energy harvesting?

Like sensors in fitness trackers?

Spot on! So, in summary, proper power management keeps MEMS devices operational, and energy harvesting opens new possibilities for their use.

Packaging and Interconnects

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now we're discussing packaging and interconnects! What do you think is the primary function of packaging in MEMS?

To protect the MEMS device!

Correct! And it allows for functional access. Why is mechanical isolation important here?

It helps to reduce stress that could affect the MEMS performance.

Exactly! Remember, packaging can influence performance metrics like damping. Can anyone give an example of interconnect techniques?

Wire bonding and flip-chip?

Spot on! Ultimately, proper packaging and interconnects are crucial for the reliability and performance of MEMS devices.

Calibration and Compensation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s move on to calibration and compensation. Why do we need calibration in MEMS systems?

Because every MEMS device might have variations in performance due to manufacturing differences.

That's spot on! Process variations can make calibration vital. What about temperature compensation?

It’s to adjust readings based on temperature changes. It's important for sensors like accelerometers, right?

Exactly! Self-test features can help too. What do they do?

They check the device's health and ensure it’s functioning correctly?

Yes! In summary, calibration and compensation enhance the accuracy and reliability of MEMS applications.

Communication and Data Handling

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let’s discuss communication and data handling for MEMS. Why is this so crucial?

MEMS need to transmit data to processors for further analysis or action.

Exactly! What wired protocols do you remember that can connect MEMS to processors?

I2C and SPI.

Great! And what about wireless communication? Can someone give an example?

Bluetooth or Wi-Fi come to mind!

Correct! Effective data handling also includes filtering, logging, and even AI-based decision-making. To wrap up, coordinating communication and data handling enhances MEMS functionalities.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

System-level design considerations of MEMS devices involve coordinated efforts between various engineering disciplines, focusing on electrical interfacing, power management, packaging, calibration, and communication strategies to ensure optimal functionality and performance.

Detailed

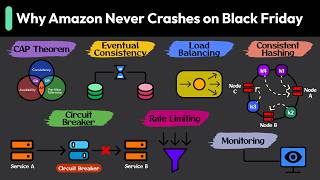

System-Level Design Considerations

Designing MEMS-based systems requires a holistic approach that brings together expertise from mechanical, electrical, software, and packaging engineering. Each design consideration plays a pivotal role in ensuring the system's performance, reliability, and scalability.

Key Considerations:

1. Electrical Interface and Signal Conditioning

MEMS devices commonly produce weak or noisy signals. To ensure optimal performance, signal conditioning is essential. Components including amplifiers, filters, and analog-to-digital converters (ADCs) play critical roles in enhancing data quality and facilitating feedback controls, especially in systems incorporating resonant elements.

2. Power Management

Power requirements can differ significantly between MEMS applications. Some applications necessitate low stable voltages, while others may require high-voltage pulses, particularly in actuators. Tailoring the power supply design to meet specific MEMS needs is crucial, alongside the potential for energy harvesting solutions in locations limited by power access

3. Packaging and Interconnects

The chosen packaging must protect MEMS devices while allowing for essential functional access. Proper thermal management, hermetic sealing, and mechanical isolation are critical to reduce the influence of environmental factors on performance. Interconnects, such as wire bonding and flip-chip methods, can also significantly affect performance metrics such as damping.

4. Calibration and Compensation

Due to inherent process variations and environmental sensitivities, calibration is necessary for accurate performance. Techniques like on-chip calibration and temperature compensation are often employed, along with self-test features that enhance reliability and maintenance capabilities.

5. Communication and Data Handling

Effective communication strategies are fundamental for MEMS devices to interface with processors and utilize data. Wired protocols like I2C, SPI, and UART are commonly employed for direct connections, while wireless communication methods (e.g., Bluetooth, LoRa, Wi-Fi) are essential for operations in IoT systems. Data processing should include filtering and logging, integrating advanced AI methodologies when applicable.

In conclusion, system-level design considers a multitude of interrelated factors that determine the overall efficacy of MEMS devices in various applications.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Interdisciplinary Coordination

Chapter 1 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Designing a MEMS-based system requires interdisciplinary coordination between mechanical, electrical, software, and packaging engineers.

Detailed Explanation

Creating a successful MEMS-based system involves collaboration among various engineering disciplines. Each type of engineer—mechanical, electrical, software, and packaging—brings unique expertise that is essential for the design and development process. Mechanical engineers focus on the physical structures and materials; electrical engineers address the circuitry and electrical interactions; software engineers develop the programming that controls the system; and packaging engineers ensure that the MEMS devices are protected and functional within their housings. This teamwork is critical because the successful integration of all these components determines the overall effectiveness and performance of the MEMS device in real-world applications.

Examples & Analogies

Imagine building a car. You need mechanical engineers to design the engine and body, electrical engineers to wire the lights and power systems, software engineers to create the interface and navigation system, and packaging engineers to decide how to assemble everything efficiently. Without communication and coordination among these groups, the car wouldn't run smoothly, just like a MEMS system needs all its disciplines to work together to function properly.

Electrical Interface and Signal Conditioning

Chapter 2 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

MEMS devices often output weak or noisy signals that need conditioning before digital processing.

- Amplifiers and Filters: To enhance signal quality.

- Analog-to-Digital Converters (ADCs): For data acquisition.

- Feedback Control: Often required in applications like resonant sensors or micromirrors.

Detailed Explanation

MEMS devices typically generate outputs that may not be sufficient for accurate digital processing, often being either too weak or too noisy. To ensure that the signals can be effectively used, various techniques are employed:

- Amplifiers and Filters are used to boost the signal strength and eliminate noise, making the output clearer.

- Analog-to-Digital Converters (ADCs) transform the analog signals from the MEMS devices into digital data so that microcontrollers or processors can interpret and use the information.

- Feedback Control is essential in applications where precision is vital, such as in resonant sensors or micromirrors, as it helps to maintain desired operational performance by automatically adjusting outputs based on real-time readings.

Examples & Analogies

Consider tuning a radio to get a clear signal. Without the right adjustments, the music might be faint or filled with static. Similarly, the electrical interface for MEMS devices fine-tunes their signals so that the data can be accurately processed and understood, just like adjusting the radio allows us to enjoy clear music.

Power Management

Chapter 3 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

MEMS devices may require low and stable voltages or high-voltage pulses (e.g., for electrostatic actuators).

- Power Supply Design: Should match MEMS voltage/current needs.

- Energy Harvesting: In remote or wearable applications, MEMS harvesters may power themselves or other modules.

Detailed Explanation

Power management is a key consideration in MEMS system design since different MEMS devices have varying power requirements. Some devices may need low and stable voltages to function correctly, while others, like electrostatic actuators, may need high-voltage pulses. To meet these needs, engineers must design power supplies that provide the optimal voltage and current levels required by each specific MEMS application. Additionally, energy harvesting techniques can offer benefits in applications where power sources are limited, such as in remote environments or wearable technologies by capturing energy from the surroundings to power the MEMS devices or associated components.

Examples & Analogies

Think about your smartphone. It requires just the right charge to keep functioning and avoid overheating. Similarly, in MEMS systems, engineers must ensure that the components receive the right power levels—just like charging a phone—to ensure everything works smoothly without draining batteries quickly. Energy harvesting is like using solar panels to charge your phone, taking advantage of available energy to extend battery life.

Packaging and Interconnects

Chapter 4 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Packaging protects the MEMS device while allowing functional access.

- Requirements: Hermetic sealing, mechanical isolation, and thermal management.

- Interconnect Techniques: Wire bonding, flip-chip, and flexible interposers.

- Impact: Packaging can influence performance (e.g., damping in resonant sensors).

Detailed Explanation

Packaging is crucial for MEMS devices as it safeguards the sensitive components from physical damage and environmental hazards while also ensuring they can still operate effectively. Key requirements include:

- Hermetic Sealing to prevent moisture and contamination, which can affect reliability.

- Mechanical Isolation to minimize vibrations that could interfere with the MEMS device's performance.

- Thermal Management to dissipate heat effectively, preventing overheating.

Interconnect techniques such as wire bonding, flip-chip methods, and flexible interposers are employed to connect the MEMS devices to other components while ensuring signal integrity. Packaging also impacts performance; for example, damping in resonant sensors can alter their responsiveness and accuracy depending on how they are packaged.

Examples & Analogies

Think of a delicate wine glass. It needs proper packaging to protect it from breaking while still allowing you to drink from it. In MEMS devices, packaging plays a similar role by protecting the components while allowing them to function correctly in the system, ensuring they can efficiently transmit and receive information without risk of damage.

Calibration and Compensation

Chapter 5 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Due to process variations and environmental sensitivity, calibration is often needed.

- On-chip Calibration: Integrating test structures and feedback loops.

- Temperature Compensation: Common in accelerometers and pressure sensors.

- Self-Test Features: Improve reliability and enable predictive maintenance.

Detailed Explanation

Calibration is necessary for MEMS devices to account for variations that may arise during manufacturing and environmental impacts that can influence functionality. Methods include:

- On-chip Calibration which involves incorporating test structures directly in the MEMS design, enabling real-time adjustments through feedback loops to ensure accurate readings.

- Temperature Compensation helps maintain accuracy in devices like accelerometers and pressure sensors, as external temperature changes can skew measurements.

- Self-Test Features improve reliability by allowing the device to assess its performance autonomously, facilitating predictive maintenance by signaling when service is needed.

Examples & Analogies

Imagine your car’s tire pressure monitoring system. It regularly checks tire pressure and adjusts for temperature changes. Similarly, MEMS devices need regular checks and adjustments to stay accurate and reliable. Just as a self-test feature can alert you to tire issues, MEMS self-tests help maintain device functionality, ensuring they perform well over time.

Communication and Data Handling

Chapter 6 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Wired Interfaces: I2C, SPI, and UART are commonly used for MEMS-to-processor communication.

- Wireless Communication: Required in IoT systems (e.g., Bluetooth, LoRa, Wi-Fi).

- Data Processing and Storage: Includes filtering, logging, and AI-based decision-making at the edge.

Detailed Explanation

Effective communication and data handling are critical in MEMS-based systems to ensure that data can be transmitted and processed accurately. Key aspects include:

- Wired Interfaces like I2C, SPI, and UART for reliable connections between MEMS and processors, allowing for efficient data transfer.

- Wireless Communication methods, such as Bluetooth, LoRa, and Wi-Fi, are vital in IoT applications, enabling devices to connect and share data without physical cables.

- Data Processing and Storage capabilities, which may involve filtering the incoming data to eliminate noise, logging historical data, and utilizing AI for decision-making, allowing the system to process information quickly and efficiently.

Examples & Analogies

Imagine a busy airport where planes, passengers, and ground staff communicate all the time. Just like clear communication is vital for the airport's operations, MEMS devices also need effective communication protocols to share data with processors. When your smartphone connects to the internet via Wi-Fi, it’s similar to how MEMS wirelessly transmit data to make decisions, like adjusting a smart thermostat based on temperatures sensed in the room.

Key Concepts

-

System integration: The process of combining mechanical, electrical, thermal, and fluidic components in MEMS devices.

-

Signal Conditioning: Techniques to improve the quality of signals received from MEMS devices for accurate processing.

-

Power Management: Tailoring power supply and energy requirements for MEMS applications.

-

Packaging: Protecting MEMS devices while maintaining access and functionality.

-

Calibration: Adjusting devices to ensure accuracy amidst variations and uncertainties.

Examples & Applications

A smartphone with integrated MEMS accelerometers and gyroscopes for orientation sensing.

An automotive airbag system employing MEMS sensors for rapid deployment.

Wearable health devices that harvest energy to power their MEMS sensors.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

To condition your MEMS signals right, | Filters and amps are in our sight!

Stories

Imagine you have a tiny sensor in a remote forest. It needs to function well, so it's wrapped carefully (packaged) to shield it from bad weather and helped by energy harvested from the sun to power itself.

Memory Tools

Remember CAPE for Calibration, Amplification, Power management, and Energy harvesting!

Acronyms

CATS represents Calibration, Amplification, Thermal management, and Signal conditioning for MEMS.

Flash Cards

Glossary

- Signal Conditioning

The process of manipulating a signal to improve its quality and readable format for processing.

- AnalogtoDigital Converter (ADC)

A device that converts analog signals into digital data, enabling processing by digital systems.

- Energy Harvesting

The process of capturing and storing energy from various sources for powering devices.

- Thermal Management

Techniques used to maintain an optimal temperature range for effective operation of devices.

- SelfTest Features

Built-in functions that allow a device to monitor its health and performance.

- Interconnects

The physical connections used to link different components within a system.

- Calibration

The process of adjusting and fine-tuning devices to ensure accurate measurements.

- Compensation

Techniques used to offset variations in measurements caused by environmental factors.

- Wired Protocols

Communication standards that use physical connections to transmit data, e.g., I2C, SPI.

- Wireless Communication

Data transmission methods that do not require a physical connection, such as Bluetooth and Wi-Fi.

Reference links

Supplementary resources to enhance your learning experience.