MEMS Integration and System Design

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to MEMS Integration

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Welcome class! Today, we're looking at the integration of MEMS into larger systems. Why do you think MEMS aren’t used alone?

Maybe because they need other components to function well?

Exactly! Integrating MEMS devices improves functionality. Think of it as teamwork—more parts working together mean a better outcome. This whole chapter is about that integration.

What components work with MEMS?

Great question! Components like signal conditioning, control logic, and communication interfaces play crucial roles. Remember the acronym SCCC—Signal Conditioning, Control logic, Communication, and Components.

I like that way to remember it!

Any other thoughts on integration? It connects everything to reliability.

Reliability sounds important for real-world applications!

You're spot on! Integration enhances reliability, crucial for systems such as MEMS in smartphones and cars.

Types of MEMS Integration

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s delve into the types of MEMS integration. Can anyone name one?

I think there's monolithic integration?

That’s correct! In monolithic integration, MEMS and electronics are fabricated on the same chip. It’s great for size and cost. Any downsides you can think of?

Maybe the processes don’t always fit well together?

Spot on! Process compatibility is key. Now, who can tell me about hybrid integration?

Is it when they create them separately and then assemble them?

Exactly! That approach offers more flexibility. Now let’s summarize this—what are the integrations we discussed?

Monolithic, Hybrid, System-in-Package, and 3D Integration!

Well done! Each integration type has its strengths and challenges.

Examples of Integrated MEMS Systems

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let’s examine some examples of integrated MEMS systems. What comes to mind?

I know smartphones use MEMS!

Correct! They utilize MEMS accelerometers and gyroscopes. How do you think that improves functionality?

They help with motion detection, right?

Exactly! Now, what about automotive systems?

They use MEMS for things like airbag systems?

Correct again! Safety is a key aspect. Lastly, can you think of a biomedical example?

Maybe implantable sensors?

Yes! MEMS are crucial in medical applications. Great job connecting these topics!

System-Level Design Considerations

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now we shift gears to the design considerations of MEMS systems. What do you think is important?

Signal conditioning sounds like it could be tricky.

Yes, exactly! Weak signals need enhancing through amplifiers and filtering. This is crucial for performance. Anyone recall other challenges?

How about power management?

Right! Power management ensures MEMS devices operate efficiently. Now, let’s summarize—what are the main considerations in designing a MEMS system?

Signal conditioning, power management, packaging, calibration, and communication!

Fantastic! Keeping these factors in mind is essential to ensure reliability and functionality.

Challenges in MEMS System Design

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let's talk about the challenges in MEMS system design. What are some major challenges?

I guess process compatibility is one?

Correct! It can be a major barrier. What else?

Environmental sensitivity seems important too.

Absolutely! Environmental factors can greatly impact performance. Let's recap these challenges—what did we cover?

Process incompatibility, environmental sensitivity, packaging stress, size-function trade-offs, and testing complexity!

Exactly! Understanding these challenges is crucial for successful MEMS design.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The chapter comprehensively outlines how MEMS devices are not standalone but are integrated into larger functional systems. It covers various integration types, examples of effective systems such as smartphones and automotive applications, as well as critical design considerations including signal conditioning, power management, and challenges in system design.

Detailed

MEMS Integration and System Design

Integrating MEMS (Micro-Electro-Mechanical Systems) into larger systems is essential for their real-world applications. This integration focuses on various components such as signal conditioning, control logic, power management, communication interfaces, and packaging, all of which significantly impact the performance, reliability, and scalability of MEMS devices.

Types of MEMS Integration

- Monolithic Integration: MEMS and electronics are fabricated on the same chip, providing advantages like reduced size and improved signal integrity while facing process compatibility challenges.

- Hybrid Integration: Involves separate fabrication followed by assembly, allowing better optimization but requiring precise alignment and bonding.

- System-in-Package (SiP): Multiple MEMS and IC components are packaged together, commonly found in smartphones and IoT devices, enhancing compactness.

- 3D Integration: Uses vertical stacking techniques to minimize the footprint, tailoring high-performance systems.

Examples of Integrated MEMS Systems

These types of integrations are evident in various applications, from smartphones that use MEMS sensors for motion detection to automotive systems that rely on MEMS for safety and monitoring. Biomedical applications also demonstrate the critical role of MEMS, such as in implantable devices.

System-Level Design Considerations

Designing MEMS-based systems is not solely an engineering challenge but necessitates collaboration across multiple disciplines.

- Signal Conditioning: MEMS output signals often require amplifiers, filters, and ADCs to prepare them for processing.

- Power Management: This includes designing power supplies to match specific MEMS requirements and exploring energy harvesting in remote applications.

- Packaging and Interconnects: Proper packaging is crucial for protecting MEMS while ensuring performance via techniques such as hermetic sealing.

- Calibration and Compensation: Due to environmental factors and precision needs, calibration plays a vital role.

- Communication and Data Handling: Systems require effective interface capabilities, whether wired or wireless.

Challenges in MEMS System Design

There are inherent challenges in MEMS design, including process incompatibility, environmental sensitivity, packaging-induced stress, performance-reliability trade-offs, and issues surrounding testing and standardization.

Co-Design and Simulation Tools

Adopting co-simulation environments helps streamline the design process by integrating MEMS structures with surrounding electronics.

In closing, MEMS integration and system design is a complex interplay of various factors, where a holistic, interdisciplinary approach ensures the maximization of MEMS device utility.

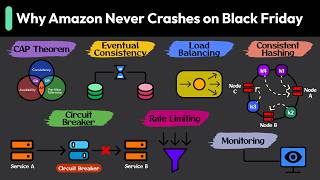

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to MEMS Integration

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

MEMS devices are rarely used in isolation. For real-world deployment, they are integrated into larger systems that include signal conditioning, control logic, power management, communication interfaces, and packaging. This chapter focuses on the integration of MEMS into functional systems and the system-level design considerations that influence performance, reliability, and scalability.

Detailed Explanation

This introduction sets the stage for understanding how MEMS (Micro-Electro-Mechanical Systems) operate in practical applications. Unlike standalone devices, MEMS are part of larger systems that work together to perform specific functions. This involves many components such as signal conditioning (to enhance the signals from MEMS), control logic (which makes decisions based on those signals), power management (to supply energy to the system), communication interfaces (to connect with other systems), and packaging (which protects the components). Overall, this integration is crucial for ensuring that MEMS can function reliably and efficiently in various applications.

Examples & Analogies

Think of MEMS like a smartphone. Just like a smartphone has many components (like a camera, GPS, and touchscreen) working together to create a fully functional device, MEMS integrate various elements to achieve complex outcomes in industries like automotive or healthcare.

Types of MEMS Integration

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Successful MEMS integration involves combining mechanical, electrical, thermal, and sometimes fluidic subsystems in a unified platform.

Detailed Explanation

Integrating MEMS into systems can be approached in several ways, each with its own characteristics, benefits, and challenges. The main types of integration include: 1. Monolithic Integration: Both MEMS and electronics are made on the same chip. This approach reduces size and improves signal quality but faces challenges with process compatibility. 2. Hybrid Integration: MEMS and electronics are produced separately and then joined together, allowing for more flexible design choices. However, this requires careful alignment and bonding. 3. System-in-Package (SiP): This method bundles various MEMS and ICs in a single module, common in compact devices like smartphones. 4. 3D Integration: Involves stacking multiple layers vertically, which helps create high-performance systems that save space. Each method addresses specific needs in performance and design.

Examples & Analogies

Consider different types of meals. A monolithic meal is a one-pot dish where everything is cooked together, simplifying the process but limiting variety. A hybrid meal could be like a platter, where different elements are cooked separately yet displayed together. A system-in-package is similar to a bento box with various foods packed in a single container, while 3D integration is like a layered cake, where each ingredient adds depth and flavor.

Examples of Integrated MEMS Systems

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Examples of Integrated MEMS Systems: ● Smartphones: Combine MEMS accelerometers, gyroscopes, and microphones with processors and wireless modules. ● Automotive Systems: Airbag systems, tire pressure monitoring, and stability control systems rely on MEMS sensors integrated with control units. ● Biomedical Devices: Implantable pressure sensors and microfluidic drug delivery systems interface with data loggers and telemetry units.

Detailed Explanation

MEMS technologies are widely applied across various industries. In smartphones, MEMS devices like accelerometers and gyroscopes enable features such as screen rotation and motion detection. Automobiles utilize MEMS sensors for critical functions like airbag deployment and tire pressure monitoring, ensuring safety and performance. In the biomedical field, MEMS devices are used in implantable sensors that monitor vital signs and in microfluidic systems that deliver drugs accurately. These examples illustrate the versatility and importance of MEMS in modern applications.

Examples & Analogies

Think of MEMS in smartphones as small assistants that help us interact with our devices. Just like a conductor leads an orchestra, MEMS lead different functionalities in smartphones, cars, and medical devices, ensuring they work in harmony to perform complex tasks.

System-Level Design Considerations

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Designing a MEMS-based system requires interdisciplinary coordination between mechanical, electrical, software, and packaging engineers.

Detailed Explanation

Creating a successful MEMS system demands collaboration among different engineering disciplines. Mechanical engineers focus on the physical structure and movement of MEMS devices, while electrical engineers deal with circuitry and signal processing. Software engineers develop the code to control these devices, and packaging engineers ensure the MEMS are correctly housed and protected. This cross-disciplinary teamwork is essential to address the complexities involved in MEMS system design, ensuring functionality and reliability across all components.

Examples & Analogies

Imagine a movie production; each department (like acting, directing, cinematography, and editing) must work together seamlessly. Similarly, MEMS design requires different engineers to collaborate just like a production team to create a coherent and well-functioning final product.

Challenges in MEMS System Design

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Designing and deploying MEMS-based systems comes with unique technical and logistical challenges: ● Process Incompatibility: MEMS fabrication processes may not align with standard CMOS workflows. ● Environmental Sensitivity: MEMS are prone to contamination, temperature changes, and mechanical shocks. ● Packaging-Induced Stress: Can affect calibration and long-term stability. ● Size vs. Function Trade-offs: Miniaturization must not compromise performance or reliability. ● Testing and Standardization: Lack of universal standards makes MEMS testing complex and costly.

Detailed Explanation

MEMS system design faces several significant hurdles. Process incompatibility arises because the manufacturing processes for MEMS often differ from those used for traditional semiconductor devices. Environmental sensitivity means that MEMS can be adversely impacted by dirt, temperature fluctuations, and physical shocks. When integrating MEMS, packaging-induced stress can lead to issues in calibration, and there is a balancing act between making MEMS smaller without losing essential functions or reliability. Furthermore, the absence of consistent testing standards complicates the verification and validation processes. These challenges require careful planning and innovative solutions to ensure that MEMS systems perform as intended.

Examples & Analogies

Imagine trying to fit various shaped puzzle pieces together. Each piece represents a different aspect of MEMS design, and if they don’t fit well together (like differing fabrication processes), the entire picture can be distorted. Similarly, environmental factors can disrupt the integrity of a design much like a rough handling of a delicate puzzle could ruin its appearance.

Key Concepts

-

MEMS Integration: The combination of MEMS devices with other electronic components for enhanced functionality and performance.

-

Monolithic Integration: Fabricating MEMS and electronics on the same chip for compact designs.

-

Hybrid Integration: Separate fabrication of MEMS and electronics before assembly.

-

System-in-Package: A packaging method that combines multiple MEMS chips in one module.

-

3D Integration: Stacking of MEMS components for space-efficient designs.

-

Signal Conditioning: Methods employed to enhance the quality of weak or noisy signals from MEMS.

-

Power Management: Strategies to manage electrical supply needs for MEMS devices.

-

Calibration: Adjusting systems for accuracy due to variations in environment or manufacturing.

Examples & Applications

These types of integrations are evident in various applications, from smartphones that use MEMS sensors for motion detection to automotive systems that rely on MEMS for safety and monitoring. Biomedical applications also demonstrate the critical role of MEMS, such as in implantable devices.

System-Level Design Considerations

Designing MEMS-based systems is not solely an engineering challenge but necessitates collaboration across multiple disciplines.

Signal Conditioning: MEMS output signals often require amplifiers, filters, and ADCs to prepare them for processing.

Power Management: This includes designing power supplies to match specific MEMS requirements and exploring energy harvesting in remote applications.

Packaging and Interconnects: Proper packaging is crucial for protecting MEMS while ensuring performance via techniques such as hermetic sealing.

Calibration and Compensation: Due to environmental factors and precision needs, calibration plays a vital role.

Communication and Data Handling: Systems require effective interface capabilities, whether wired or wireless.

Challenges in MEMS System Design

There are inherent challenges in MEMS design, including process incompatibility, environmental sensitivity, packaging-induced stress, performance-reliability trade-offs, and issues surrounding testing and standardization.

Co-Design and Simulation Tools

Adopting co-simulation environments helps streamline the design process by integrating MEMS structures with surrounding electronics.

In closing, MEMS integration and system design is a complex interplay of various factors, where a holistic, interdisciplinary approach ensures the maximization of MEMS device utility.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

In MEMS we trust, it’s a must, integrate with care, for performance fair.

Stories

AMEMS scientist dreams of a small device that could create waves of energy, but it needed the balancing act—a system around it to make it work.

Memory Tools

Remember SCCC for system integration: Signal, Control, Communication, Components.

Acronyms

We use HSM for Hybrid System Management

Hybrid Integration

Signal Conditioning

MEMS!

Flash Cards

Glossary

- MEMS

Micro-Electro-Mechanical Systems, miniature devices integrating mechanical and electrical components.

- Monolithic Integration

A method where MEMS and electronics are fabricated on the same silicon chip.

- Hybrid Integration

A method where MEMS and electronics are individually fabricated and then assembled.

- SysteminPackage (SiP)

A packaging scheme that integrates multiple MEMS components and ICs into a single package.

- 3D Integration

An approach to stack multiple MEMS layers vertically using technologies like through-silicon vias.

- Signal Conditioning

The process of refining weak signals from MEMS devices to improve quality for digital processing.

- Power Management

Techniques used to control the power needs of MEMS devices during operation.

- Calibration

The process of adjusting a system to ensure accuracy and reliability under varying conditions.

- Interconnect Techniques

Methods used to connect MEMS devices to other components for functionality.

- Telemetery

The automated process of collecting and transmitting data from MEMS sensors.

Reference links

Supplementary resources to enhance your learning experience.