Packaging and Interconnects

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Importance of Packaging in MEMS

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we are discussing the importance of packaging in MEMS. Can anyone tell me what packaging does for these devices?

It protects them from damage, right?

That's correct! Packaging protects the MEMS device while also allowing for functional access. Can anyone name additional requirements for effective packaging?

Hermetic sealing and thermal management!

Exactly! Hermetic sealing is critical to prevent moisture and contamination. Let's remember this with the acronym 'HMT' for Hermetic, Mechanical Isolation, and Thermal Management. Now, why is thermal management particularly important?

Because it keeps the device operating at the right temperatures!

Great observation! Proper thermal management ensures optimal performance.

Interconnect Techniques

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's move on to interconnect techniques in MEMS. What are common methods used for interconnecting MEMS and ICs?

I think wire bonding is one of them!

Yes, wire bonding is widely used! What are some advantages or disadvantages of wire bonding?

It can be tough to use at very small scales!

Good point. Now, how does flip-chip interconnection differ from wire bonding?

Flip-chip involves mounting the chip face-down!

Exactly! This method can lead to better thermal conduction. Let’s not forget flexible interposers, which are pretty innovative for their applications. Any ideas on their benefits?

They can allow for more flexibility in movement and design!

Absolutely! Flexibility is crucial for many applications.

Impact of Packaging on Performance

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let's discuss how packaging can impact MEMS performance. Can anyone think of an example of how packaging affects sensor functionality?

Would it dampen vibrations in resonant sensors?

Exactly! Packaging can introduce damping effects in sensors, affecting their calibration and long-term stability. Why do you think this needs to be considered during the design?

It could change how accurate the sensors are!

Precisely! Poor packaging could impair performance and reliability, making design considerations crucial. Remember, optimizing the packaging is key to overall MEMS system function.

Summarizing Key Points

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

To wrap up today’s discussions, let’s summarize the key points about packaging and interconnects. What are the primary requirements for effective MEMS packaging?

It needs hermetic sealing, mechanical isolation, and thermal management. HMT!

Well done! And what about the techniques for interconnecting MEMS? Can someone recap those?

We talked about wire bonding, flip-chip, and flexible interposers.

Excellent summary! Remember, packaging not only protects but also influences performance. This is integral to the success of MEMS systems.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Effective packaging and interconnect techniques are crucial in MEMS device integration, ensuring protection, reliability, and optimal performance by addressing critical factors such as sealing, mechanical isolation, and thermal management.

Detailed

Packaging and Interconnects in MEMS

In MEMS (Micro-Electro-Mechanical Systems), the packaging serves to protect the device while maintaining its functional accessibility. Key features of effective packaging include:

- Hermetic Sealing: Prevents moisture and contamination, essential for performance and longevity.

- Mechanical Isolation: Reduces mechanical stresses and interference, crucial for sensitive systems.

- Thermal Management: Ensures the device operates within optimal temperature ranges, essential for functionality.

Interconnect Techniques are fundamental for integrating MEMS with their environment. They include:

- Wire Bonding: Involves attaching wires to pads for electrical connections. This technique is suitable for high-frequency applications but may have limitations at extremely small scales.

- Flip-Chip: Involves mounting chips face-down for better electrical interconnection and thermal conduction, making it suitable for compact designs.

- Flexible Interposers: Allow multiple MEMS and ICs to be interconnected while providing mechanical flexibility, ideal for devices requiring movement or bending.

Impact of Packaging on Performance: The packaging choice can significantly influence the performance of MEMS devices, such as creating damping effects in resonant sensors, which consequently impacts reliability and calibration over time. This reinforces the need for careful consideration in the packaging design process as part of the overall MEMS system integration.

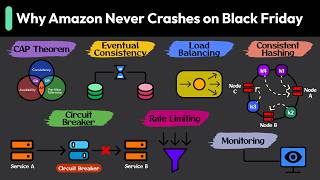

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Overview of Packaging

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Packaging protects the MEMS device while allowing functional access.

Detailed Explanation

Packaging serves a critical role in safeguarding MEMS devices from environmental factors and ensuring they can function optimally. Think of packaging as the protective casing around a delicate gadget, such as a smartphone. Without it, the internal components could be exposed to dust, moisture, and physical damage.

Examples & Analogies

Imagine you buy a fragile glass ornament. The box it comes in not only protects it from breakage during shipping but also has a design that allows you to easily admire the ornament without taking it out. Similarly, MEMS packaging allows for both protection and access to the device.

Requirements for Effective Packaging

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Requirements: Hermetic sealing, mechanical isolation, and thermal management.

Detailed Explanation

To ensure that MEMS devices operate efficiently and reliably, their packaging must meet specific requirements:

1. Hermetic sealing keeps out moisture and contaminants that could interfere with performance.

2. Mechanical isolation prevents vibrations from external sources from affecting the sensitive MEMS components.

3. Thermal management helps in dissipating heat, ensuring the device does not get damaged by overheating.

Examples & Analogies

Consider a high-performance computer. Its components are carefully placed with heat sinks and special cases that prevent excess heat buildup and damage. Similarly, MEMS devices require thoughtful design and materials in their packaging to maintain performance over time.

Interconnect Techniques

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Interconnect Techniques: Wire bonding, flip-chip, and flexible interposers.

Detailed Explanation

Interconnect techniques are methods used to connect MEMS devices to other systems or chips. Common methods include:

1. Wire bonding which uses thin wires to connect chips.

2. Flip-chip technology involves flipping the die and connecting it to the package directly, which can reduce space.

3. Flexible interposers allow for connections on non-flat surfaces, offering versatility in design.

Examples & Analogies

Think of interconnects like the way you set up a network of roads and bridges between cities. Just like those routes allow traffic to move smoothly from one place to another, interconnect techniques provide the necessary pathways for signals and power to flow between MEMS devices and other components.

Impact of Packaging on Performance

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

● Impact: Packaging can influence performance (e.g., damping in resonant sensors).

Detailed Explanation

The design and quality of packaging can greatly influence how well MEMS devices perform. For example, in resonant sensors, the packaging can affect the damping characteristics, which are crucial for their sensitivity and accuracy. If the packaging absorbs too much vibration, it could dampen the sensor's response, leading to less accurate measurements.

Examples & Analogies

Imagine a musical instrument. If it's poorly made and doesn't resonate properly, the sound can be flat and lifeless. However, a well-constructed instrument amplifies sound beautifully. Similarly, the right packaging can enhance or detract from the MEMS device's operation, impacting its overall effectiveness.

Key Concepts

-

Packaging: Vital for protecting MEMS and ensuring functionality.

-

Interconnect Techniques: Includes wire bonding, flip-chip, and flexible interposers.

-

Impact of Packaging: Packaging influences performance and reliability of MEMS devices.

Examples & Applications

Hermetic packaging prevents moisture ingress in MEMS microphones, enhancing their lifespan and accuracy.

Flip-chip technology is commonly used in smartphones for integrating MEMS sensors with other electronic components.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

HMT we declare, for MEMS packaging care, hermetic seal and thermal flair, mechanical isolation's always fair.

Stories

Imagine a little MEMS device living in a fragile world, protected by heavy armor - its hermetic seal, strong walls of mechanical isolation, and a cooling breeze keeping it at a perfect temperature, all working together to help it shine in its tasks.

Memory Tools

Remember HMT: H - Hermetic, M - Mechanical Isolation, T - Thermal management for MEMS packaging.

Acronyms

I use the acronym 'WFF' for interconnects

- Wire bonding

- Flip-chip

- Flexible Interposers.

Flash Cards

Glossary

- Hermetic Sealing

A sealing method that prevents moisture and contamination, crucial for MEMS longevity.

- Mechanical Isolation

Design feature that reduces mechanical stresses on MEMS devices.

- Thermal Management

Processes used to maintain optimal operating temperatures for MEMS devices.

- Wire Bonding

A technique to create electrical connections by attaching wires to pads.

- FlipChip

Method that mounts chips face-down to enhance thermal conduction and integration.

- Flexible Interposers

Connection elements that allow multiple components to be interconnected with flexibility.

Reference links

Supplementary resources to enhance your learning experience.