Bituminous Binder

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Role of Bituminous Binder

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we’re focusing on bituminous binders. Can anyone tell me what role they play in bituminous mixtures?

They help hold everything together, right?

Exactly! Bituminous binders act as a binding agent, ensuring that aggregates are held together effectively. They also provide waterproofing, preventing water intrusion that can lead to pavement damage.

What types of binders do we usually use?

Great question! Common types include VG-30, VG-40, CRMB, and PMB. Each of these has unique properties suited for different conditions.

What is CRMB? I haven't heard of that one before.

CRMB stands for Crumb Rubber Modified Bitumen. This binder incorporates recycled rubber to enhance its performance, especially under varying temperatures. It provides better elasticity and fatigue resistance.

How about PMB?

PMB, or Polymer Modified Bitumen, is known for enhanced elasticity and improved performance. It works well in high traffic conditions and provides better resistance to deformation.

To summarize today’s discussion: Bituminous binders are essential for binding aggregates and providing waterproofing. Common types include VG-30, VG-40, CRMB, and PMB. Each binder has specific applications that enhance pavement performance.

Importance of Binder Selection

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, why do you think selecting the right bituminous binder is critical in pavement construction?

I think it affects how long the pavement lasts.

Absolutely! The right binder can enhance durability and resistance to environmental stresses, which is crucial for the pavement’s longevity.

Does it also affect how the pavement performs under traffic loads?

Yes! Both VG-30 and VG-40, for instance, have properties designed for different traffic conditions. VG-40 is preferred for heavier traffic due to its greater stability.

So, choosing a binder isn't just about the current conditions, but also about future ones?

Exactly! You must consider future traffic loads and environmental changes when selecting a binder.

Binder Applications and Performance

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s delve into how different binders impact performance. How do you think CRMB performs differently than VG binders?

Maybe because of the rubber, it’s more flexible?

That's right! CRMB’s rubber content adds flexibility and fatigue resistance, making it ideal for varying temperatures and heavy loads.

And PMB, what would set it apart?

PMB provides excellent performance in extreme conditions and improves the overall resilience of the mixture. It’s a smart choice for high-performance applications.

What happens if you choose the wrong binder?

Choosing incorrectly can lead to premature failures, cracking, or deformation under traffic loads. It's crucial to assess the specific environmental and traffic conditions before making a selection.

To summarize, different binders like CRMB and PMB provide unique performance benefits, and selecting the right one is essential for ensuring pavement longevity.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section discusses the role of bituminous binders in pavement mix design, highlighting their function as binding agents and their common types, which include VG-30, VG-40, CRMB, and PMB. Proper selection of binders is crucial for enhanced performance and longevity of pavement.

Detailed

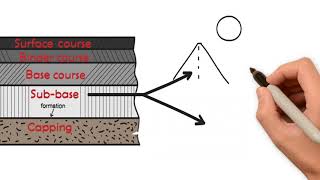

Bituminous Binder Overview

Bituminous binder serves as a critical component in bituminous mixtures, effectively functioning as a binding agent that not only adheres aggregates together but also provides key properties such as waterproofing. In the context of pavement construction, the binder's role impacts overall durability and performance under various environmental and loading conditions.

Common Types of Bituminous Binders:

- VG-30: This binder is typically used for medium traffic conditions and offers balanced durability.

- VG-40: Designed for high traffic applications, VG-40 provides excellent stability and resistance.

- CRMB (Crumb Rubber Modified Bitumen): This type incorporates recycled rubber for enhanced elasticity and durability, proving useful in varying temperature ranges.

- PMB (Polymer Modified Bitumen): Known for its superior performance, PMB enhances elasticity and allows for better fatigue resistance under traffic loads.

The selection of appropriate bituminous binder directly influences the performance, longevity, and cost-effectiveness of flexible pavements. Thus, understanding the characteristics and suitable applications for each binder type is vital for effective pavement design.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Role of Bituminous Binder

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Acts as a binding agent and provides waterproofing.

Detailed Explanation

The bituminous binder is a crucial component of a bituminous mix, primarily serving as a binding agent that holds all the aggregate materials together. This adhesive property ensures that when the asphalt mixture is laid, it maintains its structural integrity and doesn't separate under load or environmental conditions. Additionally, one of its key functionalities is waterproofing, which prevents water from penetrating the pavement, thus helping to protect the underlying layers and enhancing the longevity of the pavement.

Examples & Analogies

Imagine the bituminous binder like glue in a scrapbook. Just as glue holds all the pictures and decorations in place to create a beautiful and stable book, the bituminous binder secures the aggregates to form a strong and durable pavement. Without enough glue, the pages would fall apart. Similarly, without sufficient binder, the pavement would become brittle and prone to damage from water and heavy loads.

Types of Bituminous Binders

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

- Common types: VG-30, VG-40, CRMB (Crumb Rubber Modified Bitumen), PMB (Polymer Modified Bitumen), etc.

Detailed Explanation

There are various types of bituminous binders that are utilized in mix designs, each formulated to meet specific performance requirements. VG-30 and VG-40 are types of viscosity graded bitumen that differ in their consistency and temperature resistance, with VG-40 being suitable for higher temperature applications. CRMB incorporates recycled crumb rubber from tires to enhance the binder's elasticity and resistance to cracking and rutting, while PMB adds polymers to improve the binder's overall performance characteristics, including better durability and resistance to thermal cracking. The choice of binder type largely depends on the expected traffic loads, environmental conditions, and specific performance criteria for the pavement.

Examples & Analogies

Think of selecting a bituminous binder like choosing the right type of glue for a craft project. If you're working with lightweight paper, a standard glue stick might be enough, but for heavier materials like fabric or wood, you would need a stronger adhesive like fabric glue or wood glue. Similarly, depending on the pavement's anticipated conditions, the right type of binder needs to be chosen to ensure it can withstand stresses it will encounter, such as heavy traffic or extreme weather.

Key Concepts

-

Bituminous Binder: A crucial component that binds aggregates and provides waterproofing.

-

VG-30: A binder type for medium traffic conditions.

-

VG-40: A binder type suitable for high traffic conditions.

-

CRMB: Improved elasticity through the use of recycled rubber.

-

PMB: Enhanced performance binder optimal for high traffic applications.

Examples & Applications

Using VG-40 binder for a highway exposed to heavy traffic.

Applying CRMB in areas with extreme temperature fluctuations for improved elasticity.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Binders bind, water they keep; in roads they work, strong and deep.

Stories

Imagine a construction worker named Bob who carefully selects his binders based on traffic types – VG-30 for local roads, VG-40 for highways, CRMB for recycled benefits, and PMB for the big leagues. His roads last long and withstand all elements.

Memory Tools

Remember V for Very, C for Crumb, and P for Polymer when thinking about binders: VG-30, VG-40, CRMB, PMB.

Acronyms

To recall common binder types, think of 'VCRP' (VG-30, VG-40, CRMB, PMB).

Flash Cards

Glossary

- Bituminous Binder

A binding agent in bituminous mixtures that holds aggregates together and provides waterproofing.

- VG30

A type of bituminous binder suitable for medium traffic conditions.

- VG40

A type of bituminous binder formulated for high traffic applications.

- CRMB

Crumb Rubber Modified Bitumen, which incorporates recycled rubber to enhance elasticity and performance.

- PMB

Polymer Modified Bitumen, designed to provide enhanced elasticity and resistance under high traffic conditions.

Reference links

Supplementary resources to enhance your learning experience.