Modified Bituminous Mixes

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

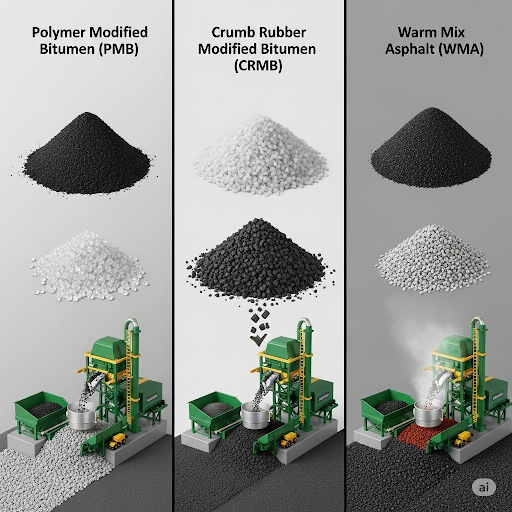

Polymer Modified Bitumen (PMB) Mixes

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we’ll start by exploring Polymer Modified Bitumen, or PMB. This type of mix improves the elasticity and temperature susceptibility of standard bitumen. Why do you think that is important?

I think it would help the pavement to be more flexible and endure temperature changes without cracking.

Exactly! PMB helps prevent cracking under stress and enhances durability. Can anyone remember why elasticity is significant in pavement design?

It makes the pavement more resilient to heavy loads and daily temperature variations.

Right! So we can remember PMB as 'Purple Magic Bitumen'—the magical element that boosts elasticity.

That’s a fun way to remember it!

Great! Now, can anyone think of a practical application for PMB in pavement construction?

Maybe in areas with a lot of extreme weather or heavy traffic?

Exactly! PMB is ideal for such conditions. To recap, PMB enhances elasticity and durability, making pavements more reliable in changing environments.

Crumb Rubber Modified Bitumen (CRMB) Mixes

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let's look at Crumb Rubber Modified Bitumen, or CRMB. What do you think is the primary material used in this mix?

Is it rubber from old tires?

Yes! It’s recycled rubber from tires, which gives the mix improved fatigue and rutting resistance. Why do you think reusing materials like this is beneficial?

It helps reduce waste and is more environmentally friendly!

Exactly! We can think of CRMB as 'Consciously Recycled Mix of Bitumen.' Can anyone recall how that impacts pavement performance?

It makes the pavement more flexible and able to handle heavy loads without breaking down.

Well said! To summarize, CRMB utilizes recycled materials for better performance and sustainability.

Warm Mix Asphalt (WMA)

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Lastly, let's analyze Warm Mix Asphalt, or WMA. Can anyone share what you know about how WMA is produced?

I think it’s made at lower temperatures than regular asphalt.

Correct! Producing WMA at lower temperatures leads to lower emissions and energy savings. Why do those factors matter?

They help to protect the environment and save resources!

Exactly, and WMA also improves workability during installation. We can remember WMA as 'Warm Means Advantageous.' What other benefits can you think of?

Maybe it helps work safely in cooler weather since it doesn't require as much heat?

Yes! Great connection. WMA is not only eco-friendly but also practical for smaller projects. To sum up, WMA is efficient in production and installation while being kind to the environment.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section outlines different types of modified bituminous mixes, including Polymer Modified Bitumen (PMB), Crumb Rubber Modified Bitumen (CRMB), and Warm Mix Asphalt (WMA). Each mix offers unique advantages regarding elasticity, durability, and environmental impact, contributing to better pavement performance.

Detailed

Modified Bituminous Mixes

Modified bituminous mixes are essential innovations in pavement technology that enhance the performance of traditional bituminous materials. This section focuses on three significant types of modified mixes:

1. Polymer Modified Bitumen (PMB) Mixes

PMB mixes involve the addition of polymers to conventional bitumen, resulting in improved elasticity and temperature susceptibility. This enhancement reduces the likelihood of cracking under stress and increases the durability of the pavement over time.

2. Crumb Rubber Modified Bitumen (CRMB) Mixes

CRMB mixes incorporate recycled rubber, often sourced from used tires. This method not only promotes sustainability by recycling waste but also enhances fatigue and rutting resistance. The incorporation of rubber improves the flexibility of the bitumen, leading to better overall pavement performance.

3. Warm Mix Asphalt (WMA)

WMA is produced at lower temperatures compared to traditional hot mix asphalt. This reduction in temperature results in several benefits, including decreased greenhouse gas emissions, energy savings during production, and improved workability during installation.

Modified bituminous mixes are significant for modern pavement design, addressing both performance and environmental concerns.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Polymer Modified Bitumen (PMB) Mixes

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Polymer Modified Bitumen (PMB) Mixes

• Improved elasticity, temperature susceptibility, and aging resistance.

Detailed Explanation

Polymer Modified Bitumen (PMB) mixes are bitumen blends that contain polymers. These additives enhance the properties of bitumen, making it more elastic, which means it can stretch and compress better under different conditions. This elasticity is vital for roads, especially in areas with varying temperatures, as it allows the material to withstand thermal expansion and contraction. Additionally, PMB mixes exhibit better resistance to aging, meaning they maintain their properties over longer periods.

Examples & Analogies

Think of PMB as a stretchy rubber band versus a regular rubber band. The PMB (stretchy band) can handle being pulled and returned to shape much better than the ordinary one (regular band), just as roads made with PMB can recover more effectively from traffic loads and temperature changes over time.

Crumb Rubber Modified Bitumen (CRMB) Mixes

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Crumb Rubber Modified Bitumen (CRMB) Mixes

• Utilizes recycled rubber; better fatigue and rutting resistance.

Detailed Explanation

Crumb Rubber Modified Bitumen (CRMB) mixes incorporate recycled rubber material, sourced typically from used tires, into the bitumen. This innovative approach not only helps in reducing waste but also enhances the performance of the asphalt binder. CRMB mixes are especially noted for their exceptional fatigue resistance, meaning they are less likely to crack or wear down under repeated loading. Furthermore, they demonstrate superior resistance to rutting, which is the deformation that occurs on pavement surfaces due to heavy traffic.

Examples & Analogies

Imagine using a flexible, recycled material like rubber to reinforce a bridge. Just as this rubber helps keep the bridge stable and functional while absorbing shocks, CRMB in asphalt helps roads handle the stresses of traffic without degrading quickly.

Warm Mix Asphalt (WMA)

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Warm Mix Asphalt (WMA)

• Produced at lower temperatures.

• Advantages: Lower emissions, energy savings, improved workability.

Detailed Explanation

Warm Mix Asphalt (WMA) is a type of asphalt that is manufactured at lower temperatures compared to traditional hot mix asphalt. This reduction in production temperature has multiple benefits: it lowers the emissions of harmful gases during mixing, saves energy since less heat is required, and improves the workability of the mix, making it easier to lay down on the road. WMA allows for extended working hours in cooler weather and also reduces the risk of heat-related issues with the asphalt during application.

Examples & Analogies

Consider baking cookies. If you bake them at a lower temperature, not only do you avoid burning the edges, but it also saves energy and can yield perfectly soft cookies. Similarly, using WMA achieves efficient asphalt laying without compromising on quality or increasing emissions.

Key Concepts

-

PMB: Enhances elasticity and durability of pavements.

-

CRMB: Utilizes recycled rubber to improve fatigue resistance and sustainability.

-

WMA: Produced at lower temperatures, reducing emissions and improving workability.

Examples & Applications

PMB is preferred for pavements in regions with extreme weather conditions to ensure long-lasting performance.

CRMB is commonly used in urban roads to utilize recycled materials while achieving better resistance to traffic loads.

WMA is particularly useful in cold climates where traditional hot mix asphalt may not be feasible for installation.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

PMB makes roads stretch and bend, not break; Durable and elastic for the earth’s sake.

Stories

Once in a town, old tires were tossed. A wise builder saw potential, no material was lost. The rubber was ground, mixed with bitumen tight, Creating CRMB—to pave roads right!

Memory Tools

Remember CRMB as 'Cleverly Reducing Material for Betterment.'

Acronyms

WMA - 'Warm Mix Advantage.'

Flash Cards

Glossary

- Polymer Modified Bitumen (PMB)

A type of bitumen enhanced with polymers to improve elasticity and temperature susceptibility.

- Crumb Rubber Modified Bitumen (CRMB)

Bitumen modified with recycled rubber particles, enhancing flexibility and resistance to fatigue.

- Warm Mix Asphalt (WMA)

Asphalt produced at lower temperatures, leading to reduced emissions and improved workability.

Reference links

Supplementary resources to enhance your learning experience.