Bituminous Mix Design Methods

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Objectives of Bituminous Mix Design

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we'll discuss the objectives of bituminous mix design. Can anyone tell me why we need specific objectives when designing a mix?

To make sure the pavement is strong and lasts a long time!

Exactly! We aim for a mixture that has adequate stability to resist deformation and sufficient durability to handle environmental conditions like water damage. Can anyone think of other objectives?

It should also be flexible and resist cracking.

Correct! Flexibility helps with fatigue resistance under repetitive loads. Here's a mnemonic to remember these objectives: 'SDFV' - Stability, Durability, Flexibility, Voids. What does ensuring adequate voids mean?

It helps with the permeability and overall durability, right?

Exactly right! In summary, the main objectives of bituminous mix design focus on stability, durability, flexibility, and adequate void content.

Components of Bituminous Mix

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's talk about the components of bituminous mix. Who can tell me what aggregates are used in the mix?

Coarse aggregates give strength!

Absolutely! Coarse aggregates support structural integrity. What about fine aggregates?

They fill the voids, right? They help make the mix workable.

Correct! And mineral fillers help with binder-aggregate adhesion. Let’s remember these with the acronym 'BFAM' - Binder, Fillers, Aggregates, Mix. What does the binder do?

It acts like glue and provides waterproofing.

Exactly! In summary, the three main components are aggregates, bituminous binder, and fillers, each contributing to the mixture's performance.

Bituminous Mix Design Parameters

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s explore the parameters used in bituminous mix design. Can anyone name one of the key parameters?

Stability!

Great! Stability refers to how well the mix can resist deformation under traffic. What about flow value?

It’s how much the mix deforms before it fails, right?

Exactly! And what do we understand by air voids?

The spaces between coated aggregates.

Very good! Let’s summarize the parameters: Stability, flow value, air voids, Voids in Mineral Aggregate (VMA), Voids Filled with Bitumen (VFB), and the Optimum Binder Content (OBC) are essential for determining performance.

Common Bituminous Mix Design Methods

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, we’re looking at the common bituminous mix design methods. Have you all heard of the Marshall Mix Design?

Yes, it’s used a lot in India!

Right! What’s the major process in Marshall's method?

Testing stability and flow after compacting the specimens.

Correct! Now, moving on, what do you know about the Superpave Mix Design?

It considers climate and traffic conditions?

Exactly! And it uses a gyratory compactor instead of the Marshall hammer. Here’s a quick way to remember: 'MSH' - Marshall, Superpave, Hveem. What does Hveem focus on?

Aggregate quality and stability measurement.

Correct! To recap, we’ve covered the Marshall, Superpave, and Hveem methods, all with unique approaches to mix design.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Bituminous mix design is vital for creating durable pavement mixtures. This section explains the key objectives of the design process, the materials involved (such as aggregates and binders), the critical parameters assessed, and details several prominent mix design methods like Marshall, Superpave, and Hveem.

Detailed

Detailed Overview of Bituminous Mix Design Methods

Bituminous mix design is essential in pavement construction, focusing on creating mixtures that provide sufficient strength, durability, and resistance to environmental factors. The primary purpose is to ensure optimal performance and longevity of flexible pavements at a reasonable cost. This section highlights:

Objectives of Bituminous Mix Design

The main goals include achieving adequate stability, ensuring durability against environmental damage, maintaining flexibility, resisting rutting and cracking, optimizing void content, and balancing the bitumen content for economic efficiency.

Components of Bituminous Mix

The mix consists of aggregates, both coarse and fine, a bituminous binder, and various additives to enhance performance. Coarse aggregates deliver strength, while fine aggregates help in workability. The binder acts as a waterproofing agent with different types used depending on performance requirements.

Bituminous Mix Design Parameters

Key parameters include stability, flow value, air voids, and optimum binder content, among others. Each of these properties plays a crucial role in determining the final mix's performance under varying conditions.

Common Mix Design Methods

The section elaborates on popular methods like the Marshall Mix Design, Superpave Method, and Hveem Method, each with unique procedures, advantages, and testing techniques, adapting to different regional requirements and advancements in technology. Finally, it touches on modified mixes and laboratory tests to evaluate these mixtures, highlighting factors that affect design and recent advancements in technology.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Introduction to Bituminous Mix Design

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Bituminous mix design is a crucial aspect of pavement construction and maintenance. It determines the proportioning of various components—aggregates, bitumen, fillers, and additives—to produce a bituminous mixture with adequate strength, durability, workability, and resistance to environmental factors and traffic loads. A well-designed bituminous mix ensures optimal performance, long service life, and cost-effectiveness of flexible pavements.

Detailed Explanation

This chunk introduces the concept of bituminous mix design, highlighting its importance in the construction and maintenance of pavements. It explains how the design involves carefully balancing different materials—like aggregates, bitumen, fillers, and additives—to create a mixture that is strong, durable, and can withstand environmental stresses and traffic loads. The goal is to ensure the pavement performs well over time while being cost-effective.

Examples & Analogies

Think of bituminous mix design like baking a cake. You need the right proportions of flour, sugar, eggs, and baking powder to create a cake that rises properly and tastes good. Similarly, mix design requires the right mix of materials to create a pavement that can bear vehicles and resist weather damages.

Objectives of Bituminous Mix Design

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• To achieve a bituminous mixture with adequate stability to resist deformation.

• To ensure sufficient durability to withstand environmental actions like water damage and oxidation.

• To maintain the right level of flexibility and fatigue resistance under repeated loading.

• To attain resistance against rutting, cracking, and stripping.

• To ensure proper void content for permeability and durability.

• To optimize bitumen content for economic and performance efficiency.

Detailed Explanation

This chunk lists the main objectives behind bituminous mix design. Each objective aims to ensure the final pavement mixture meets specific performance criteria. For instance, 'stability' refers to the mixture's ability to maintain its shape under heavy traffic; 'durability' ensures it can resist damage from environmental factors like water and heat; other points address how the mixture can flex without cracking and how to use materials efficiently to balance performance with costs.

Examples & Analogies

Imagine trying to create a pair of shoes that are not only stylish but also comfortable and durable. You want the right materials to avoid wear and tear from walking (stability) and to ensure they can withstand rainy days (durability). Similarly, the objectives for bituminous mix design focus on creating a pavement that will look good and last long, despite being under constant use and varying weather conditions.

Components of Bituminous Mix

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

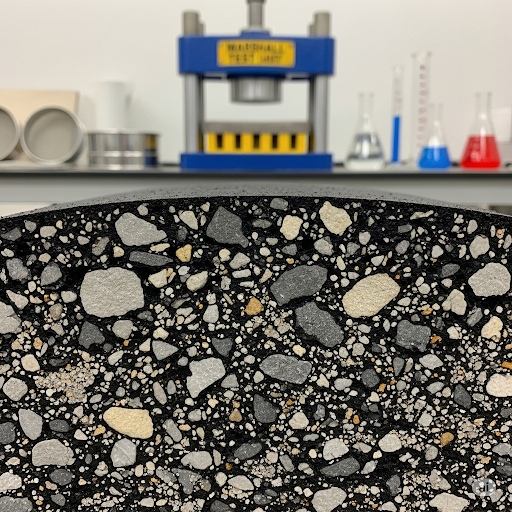

13.3.1 Aggregates

• Coarse Aggregates: Provide strength and load distribution.

• Fine Aggregates: Fill voids and improve workability.

• Mineral Filler: Fills micro-voids and enhances binder-aggregate adhesion.

13.3.2 Bituminous Binder

• Acts as a binding agent and provides waterproofing.

• Common types: VG-30, VG-40, CRMB (Crumb Rubber Modified Bitumen), PMB (Polymer Modified Bitumen), etc.

13.3.3 Additives and Modifiers

• Anti-stripping agents, warm mix additives, rubber, polymers.

• Used to enhance mix properties.

Detailed Explanation

This chunk outlines the various components that make up a bituminous mix. Aggregates are classified into coarse and fine; coarse aggregates provide strength, while fine aggregates help in making the mix workable by filling gaps. The bituminous binder is crucial as it holds the mix together and adds waterproof qualities. Various types of binders are mentioned, which can influence the mix's performance. Additionally, additives and modifiers are included to enhance certain properties of the mix, thus providing flexibility and improving durability.

Examples & Analogies

Consider building a sandwich. Coarse aggregates are like the bread that provides structure, while fine aggregates are akin to the condiments that fill in the spaces, making the sandwich more enjoyable. The binder is like the mayo or mustard that holds the entire sandwich together, ensuring all ingredients stick. Additives would be similar to special toppings that enhance flavor or texture, making the sandwich even better.

Key Concepts

-

Bituminous Mix Components: Consists of aggregates, binders, and fillers that influence the performance and quality of pavements.

-

Design Objectives: Stability, durability, flexibility, and optimal void content are critical for achieving desired pavement characteristics.

-

Common Design Methods: Includes Marshall, Superpave, and Hveem methods, each offering unique evaluation and testing criteria.

Examples & Applications

In Marshall Mix Design, varying bitumen contents can be tested to determine the optimum binder content for the best stability and flow characteristics.

The Superpave method adapts to local climate and traffic conditions to ensure the pavement's robustness.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For mixes that last and perform well, stability and durability is what we tell!

Stories

Once in a land where pavements were weak, the wise engineers toured and did seek, they found that mix design with the right bitumen, ensured roads were strong, giving joy to everyone!

Memory Tools

Remember 'SDFV' for Stability, Durability, Flexibility, Voids – key objectives of design.

Acronyms

MSH for Marshall, Superpave, Hveem – methods to remember in the realm of pavement.

Flash Cards

Glossary

- Bituminous Mix Design

The process of determining the optimal proportions of aggregates, binders, and additives to create a durable pavement mix.

- Stability

The ability of a bituminous mixture to resist deformation under load.

- Flow Value

The measure of deformation of a bituminous mixture before failure.

- Air Voids (Va)

The spaces present within a bituminous mix that are not filled with binder.

- Optimum Binder Content (OBC)

The specific amount of binder that maximizes performance in a bituminous mix.

Reference links

Supplementary resources to enhance your learning experience.