Introduction

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Importance of Bituminous Mix Design

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we are exploring bituminous mix design. Why do you think it's important in pavement construction?

It helps to ensure that the pavement can withstand traffic loads?

Exactly! A well-designed mix enhances strength, durability, and workability of pavements. Can anyone mention other benefits?

It can help reduce costs in the long run by preventing failures.

Correct! Cost-effectiveness is a significant factor. Remember the acronym DURE—Durability, Usability, Resistance, and Economy—as we go along!

Components of Bituminous Mix

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's discuss the components of a bituminous mix. What are the main components?

Aggregates, bituminous binder, and additives?

Right! Aggregates provide strength, while the binder acts as the glue holding everything together. Can anyone explain what additives do?

Additives can enhance properties like flexibility and resistance to stripping.

Precisely! Remember this—‘Batteries Enable Adjustments’ for Binder, Aggregates, and Additives.

Goals of Mix Design

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

What do you think are the main objectives of bituminous mix design?

To create a stable mixture?

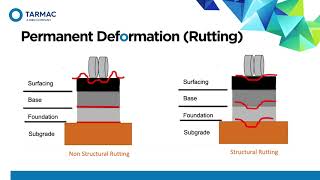

Correct! Stability is crucial. It prevents deformation under traffic loads. What other objectives are there?

Durability to withstand issues like water damage?

Exactly! We also aim for enough flexibility to resist cracking and to optimize voids for permeability. Keep in mind the acronym SDF—Stability, Durability, Flexibility!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section emphasizes the importance of bituminous mix design in ensuring the strength, durability, and workability of pavements. It outlines the systematic approach used in various methods for evaluating materials and achieving a balanced mix that withstands environmental challenges and traffic loads.

Detailed

Introduction to Bituminous Mix Design

Bituminous mix design is essential in the field of pavement construction and maintenance, playing a pivotal role in determining the appropriate proportions of aggregates, bitumen, fillers, and additives. This meticulous process aims to yield a bituminous mixture that possesses sufficient strength, durability, workability, and resistance to environmental factors and traffic loads.

A properly designed bituminous mix can significantly impact the performance and longevity of flexible pavements, making it not only crucial for immediate pavement stability but also for long-term cost-effectiveness.

This section serves as an overview of the various bituminous mix design methods employed worldwide. It highlights the systematic approaches involved in balancing different parameters, such as stiffness, stability, voids content, endurance against fatigue and rutting. Following sections will delve deeper into the mix design methods, types of materials used, testing protocols, evaluation parameters, and recent advancements in the field.

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Importance of Bituminous Mix Design

Chapter 1 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Bituminous mix design is a crucial aspect of pavement construction and maintenance. It determines the proportioning of various components—aggregates, bitumen, fillers, and additives—to produce a bituminous mixture with adequate strength, durability, workability, and resistance to environmental factors and traffic loads.

Detailed Explanation

Bituminous mix design is essential for creating pavements that will perform well over time. It involves carefully selecting and mixing materials, such as aggregates (the stones), bitumen (the glue), fillers (small particles to fill in gaps), and additives (substances that improve certain properties). The goal is to ensure that the final mixture can handle the stresses of traffic and the effects of the environment, like rain or temperature changes.

Examples & Analogies

Think of it like baking a cake. To make a delicious and sturdy cake, you need the right mix of flour, sugar, eggs, and baking powder. If you don't get the proportions right, your cake might collapse or not taste good. Similarly, bituminous mix design is about getting the right mix to create a durable and effective pavement.

Benefits of a Well-Designed Bituminous Mix

Chapter 2 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

A well-designed bituminous mix ensures optimal performance, long service life, and cost-effectiveness of flexible pavements.

Detailed Explanation

When the bituminous mix is designed correctly, it leads to pavements that not only perform better under traffic but also last longer. This longevity means that maintenance and repairs will be needed less frequently, which saves money in the long run. Furthermore, cost-effectiveness means that we can achieve the same or better quality road for a reasonable investment.

Examples & Analogies

Consider a car that is well-designed and maintained; it runs efficiently over many years. If the manufacturer did a poor job in designing the car, it would require frequent repairs and replacements, ultimately costing much more. In pavement construction, effective mix design works similarly by prolonging the life of roads.

Overview of Bituminous Mix Design Methods

Chapter 3 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

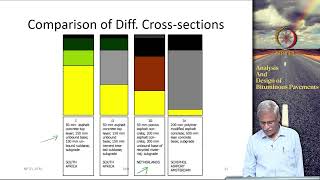

There are several bituminous mix design methods in practice globally. Each method follows a systematic approach to balance various mix parameters like stiffness, stability, voids, durability, and resistance to fatigue and rutting.

Detailed Explanation

Different techniques or methods have been developed to design bituminous mixes, as each can have its advantages based on local conditions, traffic patterns, and material availability. These methods assess how different components behave together through tests that measure properties like stiffness (how resistant the mix is to deformation) and stability (the ability to hold up under weight).

Examples & Analogies

Imagine different recipes for making pizza. Some might use thicker dough for heft, while others might favor a thin crust for crispiness. Each recipe is crafted to achieve a specific outcome, much like how different mix design methods are tailored to meet specific pavement performance needs.

Purpose of the Chapter

Chapter 4 of 4

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

This chapter provides an in-depth understanding of the different mix design methods, materials involved, testing procedures, evaluation parameters, and modern developments in mix design techniques.

Detailed Explanation

This chapter aims to give readers a comprehensive look at bituminous mix design, covering everything from the materials used to the latest advancements in the field. By the end of the chapter, students will have a solid understanding of how to approach bituminous mix design and the critical factors involved in achieving optimal pavement performance.

Examples & Analogies

Think of this chapter like a textbook for learning how to build houses. It doesn’t just tell you to put walls and a roof together; it explains the types of materials to use, the tools needed, the techniques for ensuring stability, and even the latest trends in architecture. Just as a builder becomes skilled by understanding these concepts, students will learn how to create effective bituminous mixes.

Key Concepts

-

Bituminous Mix Design: Critical for pavement performance, it balances various materials.

-

Components: Includes aggregates, a bituminous binder, and additives for enhanced properties.

-

Objectives: The main goals include stability, durability, flexibility, and economic efficiency.

Examples & Applications

In a bituminous mix, aggregates are divided into coarse and fine, which collectively enhance strength and workability.

Using additives like polymers in the mix can improve resistance to temperature changes, contributing to longer pavement life.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Mix it right, make it strong, for pavement that's safe and lasts long!

Memory Tools

DURE: Durability, Usability, Resistance, and Economy.

Acronyms

CAB

Components Include Aggregate

Binder.

Flash Cards

Glossary

- Bituminous Mix Design

The process of determining the optimal proportions of aggregates, bitumen, fillers, and additives to produce a mixture suitable for pavement construction.

- Aggregate

Materials used in construction, which are categorized into coarse and fine aggregates to enhance the properties of the bituminous mix.

- Bitumen

A viscous liquid or semi-solid form of petroleum that acts as a binder in asphalt mixtures.

- Additives

Substances added to the bituminous mix to improve its properties, such as resistance to moisture and temperature changes.

Reference links

Supplementary resources to enhance your learning experience.