Common Bituminous Mix Design Methods

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Marshall Mix Design Method

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we'll dive into the Marshall Mix Design Method, which is the most prevalent technique in India. What do you think is the first step in this method?

I think it starts with selecting the materials?

Exactly! It begins with selecting the aggregates and bitumen. After that, we prepare specimens with varying bitumen contents. What do you think those percentages might look like?

Is it around 4% to 6%?

Correct! Then, these specimens undergo compaction using a Marshall hammer. Why do you think we compact the specimens?

To assess how stable they are?

Right on! After compaction, we conduct stability and flow tests and calculate key parameters such as Air Voids, Voids in Mineral Aggregate, and Voids Filled with Bitumen. Can anyone remember what the objective of finding the Optimum Binder Content is?

To balance the mixture's properties for performance and cost?

Exactly, well done! Let's remember this using the acronym 'MIX' for Marshall: M for Materials, I for Initial Compaction, and X for eXhaustive testing. Today we learned the outline of the Marshall Mix Design Method—stay tuned for tomorrow when we cover Superpave!

Superpave Mix Design Method

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's shift to the Superpave Mix Design Method. How does this method differ from the Marshall method?

It uses a gyratory compactor instead of a hammer?

Yes! The gyratory compactor provides a better representation of field conditions. One significant aspect of Superpave is its consideration of climatic conditions and traffic loading. Can anyone elaborate on why these factors are important?

They affect how the asphalt behaves under different temperatures and weights?

Exactly! It's crucial for predicting performance effectively. This method conducts rigorous performance testing for rutting, fatigue, and moisture susceptibility. What do you think is the advantage of incorporating these tests?

It helps ensure the material lasts longer and performs better?

Absolutely! Let's remember the key points again with the acronym 'SPAVE': S for Selection of materials, P for Performance testing, A for Analysis of traffic, V for Volumetric requirements, and E for Evaluating long-term performance!

Hveem Mix Design Method

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s explore the Hveem Mix Design Method. What stands out about this method compared to the others we've learned about?

It uses a stabilometer for stability measurement, right?

That's correct! The Hveem method places a strong emphasis on aggregate quality and cohesion. Can anyone think of why aggregate quality is so crucial?

Higher quality aggregates would lead to better stability and performance of the mix?

Exactly! The process involves material selection, kneading compaction, and stability testing. After testing, how do we conclude which binder content to use?

By determining the Optimum Binder Content?

Good job! Let's memorize the Hveem method with the acronym 'HAVE': H for Hveem method, A for Aggregate quality emphasis, V for Value of the design, and E for Evaluation of stability!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

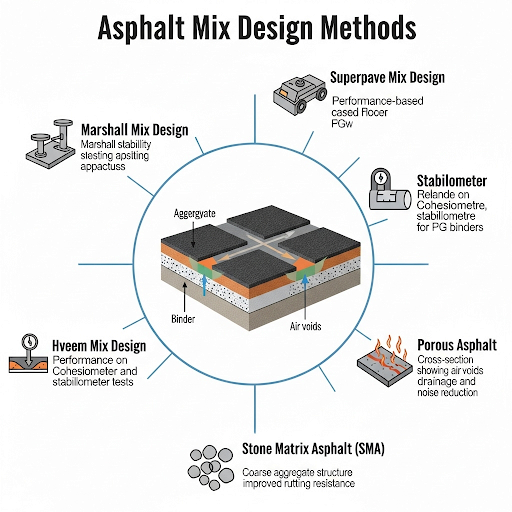

The section discusses three prominent bituminous mix design methods: the Marshall Mix Design Method, the Superpave Mix Design Method, and the Hveem Mix Design Method. Each method is described with key steps and criteria, highlighting their unique applications and advantages in ensuring the durability and performance of asphalt pavements.

Detailed

Common Bituminous Mix Design Methods

In pavement construction, the design of bituminous mixes is essential for achieving effective performance under varying environmental conditions and traffic loads. This section focuses on three principal design methods:

1. Marshall Mix Design Method

This is the most widely practiced method in India and other countries. The key steps involved are:

- Selection of aggregates and bitumen.

- Preparation of specimens with varying bitumen contents (e.g., 4% to 6%).

- Compaction using a Marshall hammer (75 blows on each side).

- Testing for stability and flow, followed by the calculation of Air Voids (Va), Voids in Mineral Aggregate (VMA), and Voids Filled with Bitumen (VFB).

- Finally, plotting a graph of bitumen content against properties to determine the Optimum Binder Content (OBC), adhering to IRC: SP: 53–2010 criteria.

2. Superpave Mix Design Method

Developed through the SHRP in the United States, this methodology incorporates traffic loading and climatic conditions into the design process. Key features include:

- Using performance grading of binders.

- Employing a gyratory compactor instead of Marshall hammer, allowing for more accurate volumetric analysis.

- Conducting performance tests for rutting, fatigue, and moisture susceptibility to predict performance effectively.

3. Hveem Mix Design Method

This method is notably used in western U.S. states, developed by Francis Hveem. It emphasizes aggregate quality and uses a stabilometer for stability measurement. It consists of material selection, kneading compaction, and stability testing with precise determination of OBC.

Understanding these methods allows engineers to select the appropriate mix design approach for specific project requirements, ensuring sustainable and effective pavement solutions.

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Marshall Mix Design Method

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Most widely used in India and several countries.

Procedure:

1. Selection of Aggregates and Bitumen.

2. Preparation of Specimens with varying bitumen content (e.g., 4%, 4.5%, 5%, 5.5%, 6%).

3. Compaction using Marshall Hammer (75 blows each face).

4. Testing: Stability and flow test.

5. Calculations: Va, VMA, VFB.

6. Plotting Graphs: Bitumen content vs properties.

7. Determination of OBC based on criteria.

Marshall Criteria for Bituminous Concrete (IRC: SP: 53–2010):

- Stability: Min 9 kN

- Flow: 2–4 mm

- Va: 3–5%

- VMA: Min 14%

- VFB: 65–75%

Detailed Explanation

The Marshall Mix Design Method is the most commonly used method for designing bituminous mixtures, particularly in India. It involves several key steps:

- Selection of Materials: The first step is to choose appropriate aggregates and bitumen based on the desired properties of the mix.

- Specimen Preparation: Specimens are prepared using different percentages of bitumen, typically ranging from 4% to 6%.

- Compaction: Each specimen is compacted using a Marshall Hammer, which applies 75 blows on each face to simulate traffic loading.

- Testing: The stability and flow of the compacted mixtures are tested to assess how well they perform under stress.

- Calculations: Important parameters like Air Voids (Va), Voids in Mineral Aggregate (VMA), and Voids Filled with Bitumen (VFB) are calculated based on the test results.

- Graphical Analysis: Graphs are plotted to show the relationship between bitumen content and the properties of the mixture.

- Determination of Optimum Binder Content (OBC): Based on the analysis, the OBC is determined to ensure a well-performing mix.

Examples & Analogies

Imagine you are baking a cake. The Marshall Mix Design Method is like experimenting with different amounts of flour (representing aggregates) and eggs (representing bitumen) to get the perfect texture and flavor. Just like you test small batches while observing how the cake rises and tastes, engineers test various bitumen contents and measure properties to find the ideal mix for road surfaces.

Superpave Mix Design Method

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Developed under the SHRP (Strategic Highway Research Program) in the USA.

Features:

- Incorporates climatic conditions and traffic loading.

- Focus on performance grading of binders.

- Uses gyratory compactor instead of Marshall hammer.

Steps:

1. Selection of aggregates and PG binder.

2. Compaction using Superpave Gyratory Compactor.

3. Volumetric analysis at different binder contents.

4. Performance testing: Rutting, fatigue, moisture susceptibility.

Advantages:

- Better performance prediction.

- Suitable for high traffic and extreme climate regions.

Detailed Explanation

The Superpave Mix Design Method was designed to address the needs identified under the Strategic Highway Research Program (SHRP) in the USA. This method focuses on:

- Material Selection: Choosing aggregates and Performance Grade (PG) binder that suit the expected conditions.

- Compaction: Instead of using a Marshall hammer, the Superpave method employs a gyratory compactor, which mimics the traffic-induced stresses more accurately.

- Volumetric Analysis: The mixture is analyzed at various bitumen contents to understand how it behaves.

- Performance Testing: Key performance characteristics such as resistance to rutting, fatigue, and moisture susceptibility are evaluated.

The main advantage of Superpave is that it provides better prediction of how mixtures will perform under different environmental conditions and traffic loads, making it especially useful for regions with extreme climates and heavy traffic.

Examples & Analogies

Think of the Superpave method like preparing an athlete for a competition. Just like trainers assess an athlete's performance via different drills and conditions to optimize their training regimen, engineers use varying materials and test for performance under various environmental factors to ensure the asphalt will hold up under real-world conditions.

Hveem Mix Design Method

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Popular in western US states, developed by Francis Hveem.

Key Features:

- Uses stabilometer for stability measurement.

- Emphasizes aggregate quality and cohesion.

Steps:

1. Selection of materials.

2. Kneading compaction of specimen.

3. Stability testing with stabilometer.

4. Determination of OBC.

Detailed Explanation

The Hveem Mix Design Method, developed by engineer Francis Hveem, is particularly popular in western states of the USA. This method emphasizes:

- Material Selection: Choosing high-quality materials is critical to ensure good performance.

- Kneading Compaction: The specimens are compacted using a kneading technique that simulates field conditions effectively.

- Stability Measurement: A stabilometer is used to assess the stability of the compacted mix.

- Optimum Binder Content: The final step is to determine the OBC to ensure optimal performance.

The focus on aggregate quality helps ensure that the mixtures provide the necessary cohesion and strength.

Examples & Analogies

You can think of the Hveem method as similar to a sculptor choosing the right type of clay for a statue. If the clay is of poor quality, no matter how skilled the sculptor is, the final sculpture might not hold up well over time. Similarly, in asphalt design, choosing quality aggregates is essential for a successful and enduring pavement.

Key Concepts

-

Bituminous Mix Design: The process of determining the proper proportions of materials in asphalt mixes to achieve optimal performance.

-

Optimum Binder Content (OBC): The ideal percentage of binder that balances various performance metrics.

-

Stability: The property of a mix that indicates its ability to resist deformation under load.

Examples & Applications

In the Marshall Mix Design Method, if the mixture has 4.5% bitumen and meets the stability requirement of at least 9 kN, it is deemed suitable for use.

In the Superpave method, a high-performance Superpave graded binder is selected for regions with extreme climate conditions.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

For stable roads, we must ensure, the right mix helps prevent the scour; Marshall’s method is quite the guide, with stability and flow beside.

Stories

Once there was an engineer who faced a challenge in designing a new road. He remembered the three vital methods: 'Marshall for stability, Superpave for weather wise, and Hveem for aggregate surprise!' With this knowledge, he confidently proceeded with the project.

Memory Tools

Remember 'SAG' for Superpave: S for climatic conditions, A for analysis of traffic variety, G for grade of binder!

Acronyms

Use 'HAVE' to recall the Hveem method

for Hveem

for Aggregate quality

for Value in design

for Evaluation!

Flash Cards

Glossary

- Marshall Mix Design Method

A method used predominantly in India for bituminous mix design focusing on stability and flow tests.

- Superpave Mix Design Method

An advanced method developed under SHRP focusing on climatic and traffic factors, employing a gyratory compactor.

- Hveem Mix Design Method

A method emphasizing aggregate quality, using a stabilometer for stability measurement in mix design.

- Optimum Binder Content (OBC)

The percentage of bitumen in a mix that optimally balances the mix properties.

- Air Voids

The spaces between coated aggregates within a bituminous mixture.

- Voids in Mineral Aggregate (VMA)

The total void space within aggregates in a bituminous mix, critical for performance.

- Voids Filled with Bitumen (VFB)

The percentage of the total void space in the aggregate that is occupied by bitumen.

Reference links

Supplementary resources to enhance your learning experience.