Challenges in Actuator Deployment

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Power Supply and Efficiency

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's start by discussing the importance of power supply in actuator deployment. Why do you think a stable power supply is crucial?

Because actuators need electricity to operate, right?

Exactly! Heavy actuators often require high-voltage power sources, especially in remote locations. This is known as 'power supply and efficiency'. Can anyone think of a situation where this might pose a problem?

Maybe in a construction site far away from the city where power sources are limited?

Right on point! Planning for efficient power management is essential. A good acronym to remember here is PEACE: Power management, Efficiency, Accessibility, Compatibility, and Environmentally friendly. Let's keep this in mind as we progress!

Heat Dissipation

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let's discuss heat dissipation. What happens to electric actuators when they operate continuously?

They can overheat, right?

Correct! Overheating can lead to failures or inefficiencies. It's essential to manage heat dissipation through proper design. Has anyone seen this in action?

I think in some machines, they have cooling systems incorporated.

Absolutely! A simple mnemonic to recall this is 'COOL': Continuous Operation Observed with Limitations. Always consider thermal management in actuator design.

Environmental Protection

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s discuss the importance of protecting actuators from environmental factors. What do you think are the main threats?

Dust and moisture, especially if they're outdoor actuators.

Exactly! Environmental threats like dust, water, and corrosion can compromise actuator reliability. Why is this especially critical in automation?

If they fail, the whole automated system could stop working!

Spot on! Remember RMPS: Reliability, Maintenance, Protection, and Safety when considering actuator environments.

Control Complexity

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s move on to control complexity. Why might high-precision applications require more sophisticated controllers?

They need better accuracy and responsiveness, and that comes with a cost.

Right! Complex control systems can enhance performance but also increase costs. Can anyone provide an example of expensive control systems?

I know that robotics often requires advanced controllers that are quite pricey!

Exactly, consider the trade-offs between performance and cost with the acronym CAP: Control Algorithms & Performance. It’s about managing those complexities effectively.

Maintenance and Reliability

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Finally, let's talk about maintenance and reliability. Why do hydraulic and pneumatic systems need more regular maintenance?

Because they have seals and pressure components that can wear out.

Perfect! Regular maintenance helps prevent leaks and failures. A good mnemonic for this is 'PRESERVE': Periodic checks and Repairs Ensure System Reliability and Efficiency. Maintenance is crucial for longevity!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section identifies key challenges in actuator deployment, including power supply demands, heat dissipation, environmental protection, control complexity, and maintenance needs. These challenges can significantly impact the functionality and reliability of actuators in automated systems.

Detailed

Challenges in Actuator Deployment

While actuators are indispensable components in automation systems, their effective deployment is not without challenges. This section highlights several practical hurdles that engineers and designers encounter when integrating actuators into systems:

- Power Supply and Efficiency: Heavy actuators often require stable high-voltage power sources, which can be a significant constraint, especially in remote or temporary construction sites.

- Heat Dissipation: Electric actuators may overheat during continuous operation, which necessitates careful thermal management strategies to ensure reliability.

- Environmental Protection: Actuators operating in outdoor or industrial settings must be protected from harmful elements such as dust, moisture, and corrosion to maintain their integrity and functionality.

- Control Complexity: High-precision applications typically involve complex and expensive control systems, which can increase the overall cost and technical demands.

- Maintenance and Reliability: Hydraulic and pneumatic actuators require regular maintenance, including checking seals and pressure systems, to prevent leaks and ensure reliable operation.

These challenges necessitate thorough planning and engineering considerations during the actuator selection and integration process, ensuring that the chosen actuators meet application needs without excessive compromise.

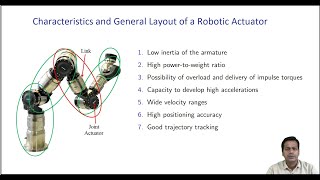

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Power Supply and Efficiency

Chapter 1 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Heavy actuators may require high-voltage or stable power sources, especially in remote construction sites.

Detailed Explanation

This chunk explains that heavy actuators need a reliable and often high-voltage power supply. This is crucial because if the power supply is unstable or insufficient, the actuator might not function properly, leading to equipment failure or inefficiency. In remote construction sites, where access to reliable power sources can be difficult, this poses a significant challenge.

Examples & Analogies

Imagine trying to power a large construction crane using a weak battery; it would struggle to lift heavy loads and could eventually stop working altogether. Just as a car needs fuel to run smoothly, actuators need a strong and stable power supply to operate effectively.

Heat Dissipation

Chapter 2 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Electric actuators can overheat in continuous duty cycles.

Detailed Explanation

This chunk highlights the issue of heat generation in electric actuators. When they operate continuously, such as in repetitive tasks on assembly lines, they can generate a lot of heat. If this heat is not dissipated properly, it can damage the actuator, leading to performance issues or failures. Managing heat is important for maintaining operational efficiency and longevity.

Examples & Analogies

It's similar to how a computer can overheat if it runs too many programs at once without sufficient cooling. Just like computers use fans to keep cool, actuators might need cooling systems to prevent them from overheating.

Environmental Protection

Chapter 3 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Actuators in outdoor or industrial environments must be protected from dust, water, and corrosion.

Detailed Explanation

This chunk addresses the necessity of protecting actuators from environmental hazards. In settings like construction sites or outdoor applications, actuators can be exposed to harsh conditions such as dust, water, and corrosive substances. If not properly protected, these elements can lead to malfunction or damage, which can compromise the entire system's operation. This protection can include using seals, housings, or coatings to safeguard the actuators.

Examples & Analogies

Think of a smartphone that can get damaged by water or dust. Just as we use waterproof cases or screen protectors to shield our phones, actuators need similar protective measures to function correctly even in tough environments.

Control Complexity

Chapter 4 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

High-precision applications demand complex and costly controllers.

Detailed Explanation

This chunk emphasizes that when actuators are used in high-precision tasks, the control systems required are often complex and expensive. High precision means that the actuator must be able to perform with very small tolerances, which typically involves advanced algorithms and sensors that can increase the overall costs of the system. This complexity is necessary to ensure accuracy and reliability in the actuator's performance.

Examples & Analogies

Consider a high-end camera that needs precise lenses and focus mechanisms to take great photos. The advanced technology inside such cameras is what makes them expensive, just as precise actuators need sophisticated controls to operate effectively in critical applications.

Maintenance and Reliability

Chapter 5 of 5

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Hydraulic and pneumatic systems need regular maintenance for seals, pressure regulation, and leakage prevention.

Detailed Explanation

This chunk discusses the maintenance challenges of hydraulic and pneumatic systems. These systems often have components that require regular upkeep, such as seals and pressure regulators. If maintenance is neglected, these systems can experience leaks or malfunctions, which can lead to system failures. Regular checks and maintenance activities ensure that these systems remain reliable and perform efficiently over time.

Examples & Analogies

Think of the regular oil changes and tire rotations required for a car to keep running smoothly. Just like a car needs maintenance to ensure reliability and prevent breakdowns, hydraulic and pneumatic systems have similar needs to remain dependable.

Key Concepts

-

Power Supply: Critical for actuator operation; stability is key.

-

Heat Dissipation: Essential to prevent overheating in electric actuators.

-

Environmental Protection: Necessary to extend actuator life in various settings.

-

Control Complexity: Must be balanced against cost and needs for high-precision tasks.

-

Maintenance: Regular upkeep is vital for ensuring actuator reliability.

Examples & Applications

An electric actuator used in robotics might require a stable power source to function effectively, particularly in a remote location.

Hydraulic actuators in heavy machinery need regular inspections to ensure seals and pressure regulations are intact, preventing potential failures.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

To keep our actuators bright and fine, power and heat, we must align.

Stories

Imagine a team of engineers at a construction site. They needed strong actuators to lift heavy beams, but found they kept shutting down because the power wasn't stable. They learned to secure a reliable energy source—keeping their project on track! A lesson in security!

Memory Tools

Remember PEACE: Power management, Efficiency, Accessibility, Compatibility, and Environmentally friendly—factors needed for actuator power supply.

Acronyms

Use RMPS to remember Reliability, Maintenance, Protection, and Safety for actuator health!

Flash Cards

Glossary

- Power Supply

The source of electrical energy required to operate actuators.

- Heat Dissipation

The process of releasing heat from an operating actuator to prevent overheating.

- Environmental Protection

Measures taken to safeguard actuators from dust, moisture, and corrosion.

- Control Complexity

The level of sophistication and intricacy of the control systems required for actuator operation.

- Maintenance

The routine checks and repairs necessary to ensure actuator reliability and functioning.

Reference links

Supplementary resources to enhance your learning experience.