Pneumatic Actuators - 7.4.2

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Pneumatic Actuators

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we will be discussing pneumatic actuators! Can anyone tell me what a pneumatic actuator is?

I think it's a device that moves using air.

Exactly! Pneumatic actuators utilize compressed air to create motion. They are commonly used in various applications, especially where speed is crucial. What are some examples you can think of?

Maybe in factory automation and robotic arms?

Yes, great examples! They are indeed found in automated production lines. Remember, they are generally lightweight and very efficient for quick tasks. Now, why do you think air is a good medium for these actuators?

Air is abundant and easy to compress!

That's right! Plus, it's safe to use in many environments. Before we move on, let's remember that air's compressibility can be a limitation when high precision is needed.

Advantages of Pneumatic Actuators

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Moving on to the advantages, can someone list a few benefits of using pneumatic actuators?

They are low-cost and very fast!

Correct! They are also incredibly reliable and operate well in explosive environments since they don't use electricity. Let’s talk briefly about a mnemonic to remember these advantages. How about 'FLEES'—for Fast, Low-cost, Efficient, Explosive safety?

I like that! So swift and safe!

Exactly! Now, who can tell me what kind of applications they are commonly used in?

Like robotic arms and automated doors?

Well done! Their speed and safety make them ideal for those applications.

Limitations of Pneumatic Actuators

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s move on to the limitations of pneumatic actuators. Can someone remind me what that might be?

I think they don't produce as much force compared to hydraulic actuators?

That’s correct! They are lower in force output. This is crucial when considering heavy loads. Can anyone think of another limitation?

Is it the accuracy? Because of air compression?

Absolutely! The compressibility of air causes potential inaccuracies. A mnemonic here could be 'FCA' for Force, Compressibility, Accuracy. Can you summarize that for me, Student_4?

Pneumatic actuators have limitations like weaker force output and issues with accuracy due to air's compressibility.

Well summarized! Understanding these limitations helps us choose the right actuator for specific applications.

Applications and Real-World Usage

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s finish with the applications of pneumatic actuators. Where do we see them in action, students?

In factories, using robotic arms.

And in automated doors.

Correct! They are widely used in these areas due to their speed and efficiency. Also, what about their application in hazardous environments?

They’re safer than electric actuators, right?

Exactly! Safety is a key reason for their use in explosive environments. Before we wrap up, let’s recap the key points of our discussion on pneumatic actuators.

They are fast, low-cost, but less powerful and less accurate compared to other types!

Perfect summary! Remember these points for our upcoming quiz!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

This section details the function of pneumatic actuators, highlighting their advantages such as low cost and high speed, along with limitations like lower force output compared to hydraulic actuators. The significance of these actuators in automation systems and their application in industrial tasks is emphasized.

Detailed

Pneumatic Actuators

Pneumatic actuators are essential components in automation systems that utilize compressed air to generate mechanical motion. They are known for their lightweight construction and are particularly effective for tasks that require quick and repetitive movements. Common applications include robotic arms, automatic doors, and control valves in industrial settings.

Advantages of Pneumatic Actuators:

- Low Cost: They tend to have lower initial costs compared to electrical and hydraulic options.

- High Speed: Pneumatic actuators excel in high-speed applications due to the rapid response of compressed air.

- Safety in Explosive Environments: Using air instead of electricity minimizes risks of ignition in hazardous areas.

Limitations of Pneumatic Actuators:

- Lower Force Output: When compared to hydraulic actuators, pneumatic systems typically generate less force.

- Compressibility of Air: The inherent compressibility of air can reduce precision in applications requiring high accuracy.

In summary, pneumatic actuators are pivotal in many automated processes, offering a balance of speed and safety while being economical for various applications.

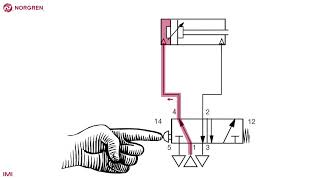

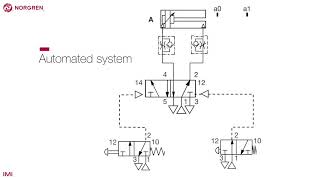

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Definition of Pneumatic Actuators

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

• Use compressed air for actuation.

• Lightweight and ideal for simple automation.

• Common in automated production lines.

Detailed Explanation

Pneumatic actuators are devices that use compressed air to produce movement. They are designed to be lightweight, making them suitable for applications where reducing weight is important. These actuators are commonly used in environments that require simple automation, such as production lines in factories, where they can control machinery and processes efficiently.

Examples & Analogies

Imagine a balloon (which represents compressed air). When you release the air from the balloon, it propels itself forward. This is similar to how pneumatic actuators work by using compressed air to create movement, often causing machines to perform tasks such as moving items along a conveyor belt.

Advantages of Pneumatic Actuators

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Advantages:

• Low cost

• High speed

• Safe in explosive environments

Detailed Explanation

Pneumatic actuators offer several advantages. They are generally low-cost compared to electrical and hydraulic systems, making them an economical choice for many automation tasks. They operate at high speeds, which is beneficial for applications that require rapid movement. Additionally, they are safe to use in explosive environments because they do not produce sparks, unlike electric motors that might create electrical sparks.

Examples & Analogies

Think of a balloon again. Releasing air rapidly can propel it quickly across a room. Similarly, pneumatic actuators can quickly drive motions in machines. Moreover, since they operate on air, you can use them in places like paint spray booths where electric devices could ignite flammable materials.

Limitations of Pneumatic Actuators

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Limitations:

• Lower force than hydraulic

• Compressibility of air reduces accuracy

Detailed Explanation

While pneumatic actuators have benefits, they also come with limitations. They produce lower force output compared to hydraulic actuators, which can move heavier loads. This makes them less suitable for tasks that require high power and heavy lifting. Additionally, the compressibility of air can reduce the precision of movements. When air is compressed and released, it doesn't always produce the exact same amount of force, which can lead to variations in performance.

Examples & Analogies

If you think of squeezing a sponge, you know that depending on how much you squeeze, the sponge can release water at different rates. This can be likened to how pneumatic actuators operate under varying conditions. Just like you can't always predict how fast or how much water will come out based on your squeeze, pneumatic actuators can be inconsistent in their force outputs due to the nature of compressed air.

Key Concepts

-

Pneumatic Actuators: Devices that convert compressed air into mechanical motion.

-

Advantages: Low cost, high speed, and safety in hazardous areas.

-

Limitations: Lower force output and reduced accuracy due to air compressibility.

-

Applications: Commonly used in industrial automation and robotics.

Examples & Applications

Example 1: A robotic arm using pneumatic actuators for precise control during assembly tasks.

Example 2: Automatic doors that open and close using pneumatic-driven actuators.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Pneumatics take flight, so light and so bright, with air under pressure, they'll move with great might.

Stories

Imagine a factory where doors fly open and arms work seamlessly, all powered by the magic of air!

Memory Tools

Remember 'FLEES' - Fast, Low-cost, Efficient, Explosive safety for advantages of pneumatic actuators.

Acronyms

FCA—Force, Compressibility, Accuracy; key limitations of pneumatic actuators.

Flash Cards

Glossary

- Pneumatic Actuators

Devices that use compressed air to create mechanical motion.

- Compressed Air

Air kept at a pressure significantly higher than atmospheric pressure, often used to power pneumatic systems.

- Force Output

The amount of force generated by an actuator to perform work.

- Compressibility

The ability of a substance to decrease in volume under pressure, affecting accuracy in systems.

Reference links

Supplementary resources to enhance your learning experience.