Role of Actuators in Automation

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Actuators

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're diving into the role of actuators in automation. Let's start with a basic question: What do you think an actuator does?

Isn't it a device that causes movement?

Correct! Actuators convert digital signals into mechanical motion. They are the muscles that execute tasks in automated systems. Can anyone give me an example of where we've seen actuators used?

What about in robotic arms?

Exactly! Robotic arms use actuators to move their joints. Think of the acronym 'AIM'—Actuators In Motion. This can help us remember their purpose.

Applications of Actuators

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let’s talk about where actuators are applied. Can anyone list some automation systems that use actuators?

Building management systems?

And smart construction like cranes!

Great examples! Actuators control HVAC systems, adjust lighting, and even operate automated guided vehicles! These applications show how essential actuators are in our current technologies.

What happens if the actuator fails?

Excellent question! A failure could lead to incorrect operations, resulting in energy inefficiency or unsafe conditions.

Understanding Controllers and Actuators

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let’s now explore how actuators work in conjunction with controllers. Who can remind us what a controller does?

It processes inputs from sensors, right?

Precisely! The controller analyzes data and sends commands to actuators to perform specific actions. Together, they create a closed-loop system. Remember the acronym 'C-AC'—Controllers And Actuators to visualize their collaboration.

What do you mean by closed-loop?

A closed-loop system uses feedback to improve accuracy. For example, a servo motor adjusts its position based on sensor input to maintain precision.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

The section discusses the central role of actuators in automation systems, where they convert digital signals from controllers into real-world movements, facilitating various applications from robotic arms to building management systems.

Detailed

Role of Actuators in Automation

Actuators play a crucial role in executing automated tasks within various systems. They function by translating digital decisions made by controllers (such as PLCs, microcontrollers, or SCADA systems) into real-world physical actions, which are essential for the performance of automated systems. This section highlights the significant applications of actuators across different automated setups, including:

- Robotic Arms: Each joint is driven by actuators to enable precise movements.

- Automated Guided Vehicles (AGVs): Motors assist with navigation.

- Building Management Systems: Actuators control damper positions, lighting adjustments, and automated blinds.

- Smart Construction: Hydraulic actuators are used significantly in machinery like excavators and cranes.

- Civil Infrastructure Monitoring: Actuators enable automated inspection robots or structural elements that adjust themselves.

Understanding the role of actuators is foundational in designing efficient automation systems and realizing the full potential of smart technologies in various engineering and industrial fields.

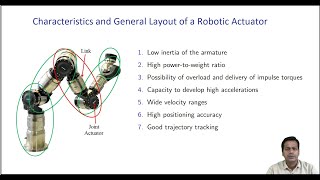

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Central Role of Actuators

Chapter 1 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Actuators are central to executing automated tasks. They translate digital decisions from controllers (PLCs, microcontrollers, SCADA systems) into real-world physical actions.

Detailed Explanation

Actuators serve as the bridge between digital commands from controllers and physical tasks in the real world. When a controller makes a decision—such as moving a robotic arm or adjusting a valve—it sends a digital signal to an actuator, which then converts this signal into physical movement. This process is crucial in automation systems, as it allows machines and robots to perform specific actions effectively and accurately.

Examples & Analogies

Imagine a remote-controlled car. When you press a button on the controller, it sends a signal to the car to move forward, backward, or turn. The actuator in the car converts your command into motion, much like how actuators in automated systems interpret digital signals and perform tasks.

Applications of Actuators in Automation Systems

Chapter 2 of 2

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Applications in Automation Systems:

• Robotic arms – Actuators drive each joint to move precisely.

• Automated guided vehicles (AGVs) – Motors help in navigation.

• Building management systems – Control HVAC dampers, lighting adjustments, automated blinds.

• Smart construction – Hydraulic actuators in excavators and cranes.

• Civil infrastructure monitoring – Actuators used in automated inspection robots or self-adjusting structural elements.

Detailed Explanation

Actuators are applied across various sectors in automation. For example, robotic arms utilize actuators at their joints to achieve precise movements for tasks like assembly or welding. In automated guided vehicles (AGVs), actuators control movement and navigation. Building management systems use actuators to manage HVAC systems efficiently, adjusting elements like dampers and lighting based on occupancy or time of day. In construction, hydraulic actuators power heavy machinery for lifting and moving materials. Additionally, civil infrastructure employs actuators for monitoring structures and performing inspections automatically.

Examples & Analogies

Think about a smartphone's various functions. Just as the internal components of the phone work together (like touch sensors responding to taps), different types of actuators in automation work in harmony to perform complex, automated tasks across various applications. For instance, a robotic arm in a factory might pick up an item thanks to the coordination of several actuators.

Key Concepts

-

Actuator: Converts signals into motion.

-

Controller: Processes input signals.

-

Closed-Loop System: Utilizes feedback for control.

-

Applications of Actuators: Found in robotics, smart buildings, and construction.

Examples & Applications

Robotic arms that move through actuators for precision tasks.

Building management systems controlling blinds and HVAC systems using actuators.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Actuators move, just like a groove, converting signals with every move.

Stories

Imagine a robot arm in a factory; it swings and turns at the command of a controller, showing how actuators bring life to the machines.

Memory Tools

AIM - Actuators In Motion helps remember what actuators do in automation.

Acronyms

C-AC for Controllers And Actuators highlights their collaborative role in automation.

Flash Cards

Glossary

- Actuator

A device that converts control signals into mechanical motion or action.

- Controller

A device that processes input from sensors and sends commands to actuators.

- PLC

Programmable Logic Controller, a common type of industrial control system.

- SCADA

Supervisory Control and Data Acquisition, a system for overseeing and controlling industrial processes.

- ClosedLoop System

A control system that uses feedback to compare the actual output with the desired output.

Reference links

Supplementary resources to enhance your learning experience.