Pneumatic Actuators - 7.2.1.3

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Pneumatic Actuators

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we'll explore pneumatic actuators. Can anyone tell me what an actuator is?

Is it something that causes movement in machines?

Exactly! Pneumatic actuators specifically use compressed air. They convert air pressure into mechanical motion. What kind of tasks do you think they excel in?

Maybe in tasks that need to be done quickly and repetitively?

That's right! High speed and repetitive motion are key advantages. Let's remember that with the acronym FAST: Fast, Actuates, Simple, Tasks. Now, can anyone think of an application for pneumatic actuators?

How about in robotic arms?

Good example! They’re also used in valves and conveyor belts. To recap, pneumatic actuators are FAST: they perform fast tasks effectively and simply.

Advantages and Limitations of Pneumatic Actuators

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's dive into the advantages of pneumatic actuators. Can you name a few advantages?

I think they are cost-effective and lightweight!

Yes! They’re known for being low-cost and lightweight. Another advantage is their safety in explosive environments due to their compressibility. However, can anyone tell me what limitations they have?

Maybe they can't exert as much force as hydraulic actuators?

Exactly! Pneumatic actuators usually provide lower force than hydraulic systems and may have accuracy issues. Let's remember the LIMIT acronym: Low force, Inaccuracy, Maintenance needed, Inconsistent volume, Too light.

That's a great way to remember it!

So, to sum up, pneumatic actuators are cost-effective and safe, but they face limitations when it comes to force and accuracy.

Applications of Pneumatic Actuators

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's discuss practical applications. How are pneumatic actuators used in industrial settings?

I think they’re used to control machine parts, like valves in assembly lines.

Great! They are indeed used in assembly lines for tasks like valve control. Can anyone think of another application?

What about in packaging machines?

Excellent! Packaging machines benefit from the speed of pneumatic actuators. Let’s remember applications using the word 'VALVE'—Valves, Arms (robotic), Lift doors, Vehicles, and Equipment control. Now, how do these applications enhance efficiency?

They help to automate processes!

Exactly! Pneumatic actuators are pivotal in automation, making processes faster and more efficient.

Integration with Control Systems

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Next, let’s discuss how pneumatic actuators are integrated with control systems. Who can explain this interaction?

They work with sensors to detect positions, right?

Correct! They’re part of a closed loop with sensors and controllers. What are the two main types of control methods?

Open-loop and closed-loop control?

Exactly! Open-loop is simple without feedback, while closed-loop uses feedback for precision. Can anyone provide an example of each?

A fan motor could be open-loop, and a robotic arm with a position sensor would be closed-loop.

Great examples! To sum it up, pneumatic actuators function best when integrated with control systems, utilizing both open and closed-loop control methods.

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

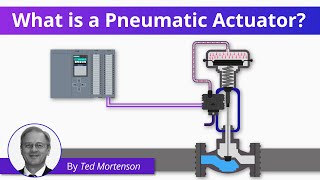

Pneumatic actuators are essential components in automation systems, leveraging compressed air for movement. They are light, cost-effective, and excel in high-speed applications, although they have limitations in force output and accuracy compared to hydraulic actuators.

Detailed

Pneumatic Actuators

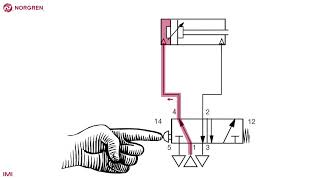

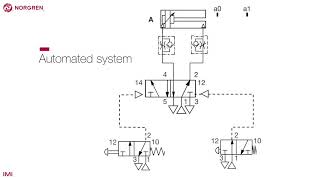

Pneumatic actuators are devices that utilize compressed air to create motion or control mechanisms in automation systems. They are widely recognized for their ability to perform fast, repetitive tasks, making them ideal for applications like robotic arms or control valves. These actuators convert the energy from compressed air into mechanical motion, contributing significantly to various automation processes.

Key Points Covered:

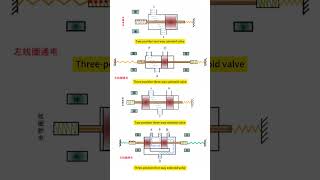

- Mechanism: Pneumatic actuators operate by using compressed air as the driving force, translating energy into linear or rotary motion.

- Applications: Commonly found in contexts such as manufacturing lines, doors, valves, and various robotic systems.

- Advantages: They offer low costs, high speeds, and operational safety in explosive environments.

- Limitations: Pneumatic actuators typically provide lower force output than hydraulic actuators and can suffer from accuracy issues due to the compressibility of air.

Understanding the function and integration of pneumatic actuators is essential for engineers and automation designers, ensuring optimal choices are made for specific applications.

Youtube Videos

Key Concepts

-

Compressed Air: Energy source for pneumatic actuators.

-

High-Speed Operation: Key advantage of pneumatic actuators.

-

Low Force Output: A limitation in comparison with hydraulic actuators.

-

Closed-loop and Open-loop Control: Two types of integrating systems with actuators.

-

Automation: Core function of pneumatic actuators in various industries.

Examples & Applications

Pneumatic actuators are used in automated assembly lines to control the movement of parts.

They can operate doors in automated systems allowing for efficient access.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Pneumatics drive, fast they strive; in the air, they thrive!

Stories

Imagine a factory where light as a feather robotic arms dance around. They swiftly push against boxes using air, making everything seem effortless and efficient. This is the magic of pneumatic actuators in action!

Memory Tools

Remember 'FAST' for pneumatic actuators: Fast, Actuates, Simple, Tasks.

Acronyms

Use 'LIMIT' to recall pneumatic actuator limitations

Low force

Inaccuracy

Maintenance needed

Inconsistent volume

Too light.

Flash Cards

Glossary

- Pneumatic Actuator

A device that uses compressed air to create mechanical motion.

- Closedloop Control

A control method that uses feedback to improve accuracy.

- Openloop Control

A control method without feedback, usually less precise.

- Force Output

The amount of force an actuator can exert.

- Linear Motion

Motion that occurs in a straight line.

- Rotary Motion

Motion that occurs in a circular path.

Reference links

Supplementary resources to enhance your learning experience.