Effects on Concrete - 6.3.3

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Introduction to Effects of Mineral Admixtures

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today we are going to discuss the effects of mineral admixtures on concrete. Can anyone define what a mineral admixture is?

Are they materials added to concrete to improve its properties? I’ve heard about them before.

Exactly! Mineral admixtures are finely divided materials added to concrete to enhance workability, strength, durability, and sustainability. Can anyone name a few types of mineral admixtures?

Fly ash, silica fume, and GGBS are some of them, right?

Correct! And remember their properties play a major role in how they affect concrete performance. For instance, fly ash improves workability and strength in the long term. An easy way to remember these benefits is the acronym WES: Workability, Enhancement of strength, and Sustainability.

That’s a helpful acronym!

Great! Let's move on to explore how each of these admixtures uniquely impacts concrete.

Specific Effects of Fly Ash

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's take fly ash as an example. Can anyone tell me what it is and how it affects concrete?

Isn't it a by-product from burning coal? It makes concrete stronger over time!

Exactly! Fly ash helps improve workability and reduces the water demand. It also enhances long-term strength, but it might slow down the early strength gain. Can someone remind us what we might do to address that?

We could use superplasticizers to help with that!

Precisely! Remember this: as we use fly ash, we should manage our expectations for early strength while looking forward to long-term benefits.

So we focus on long-term performance when using fly ash?

That’s right! Summarizing, fly ash is beneficial for working conditions and offers long-term improvements in strength.

Effects of Silica Fume and GGBS

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now, let's discuss silica fume. Who can explain its effects on concrete?

It's very fine, right? It can improve the compressive strength and reduces permeability.

Exactly! Silica fume can significantly enhance strength but may increase water demand. What’s the term we often associate with this?

Thixotropy! It makes the mix thicker and requires superplasticizers.

Correct! Finally, what about GGBS? How does it contribute to concrete mixture?

It enhances durability and reduces heat of hydration, especially important for massive structures.

Great point! In conclusion, silica fume gives immediate strength benefits, while GGBS plays a key role in developing long-term durability.

Overall Impact on Concrete Properties

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

So, to wrap up, how do mineral admixtures influence concrete properties?

They improve workability, reduce permeability, and enhance durability!

Exactly! They also modify the heat of hydration and can reduce the risk of alkali-silica reactions. What’s a good way to recall their benefits?

We could say 'WPD for concrete'—Workability, Permeability reduction, Durability!

Perfect mnemonic! Always keep in mind how these factors work together towards creating sustainable and durable concrete. Good job today, everyone!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

Mineral admixtures significantly enhance concrete's workability, durability, strength, and sustainability. They influence hydration processes, reduce permeability, and assist in controlling heat of hydration, depending on their type and properties.

Detailed

In this section, we explore the various effects that mineral admixtures have on concrete, specifically focusing on properties such as workability and strength. Mineral admixtures (like fly ash, silica fume, and GGBS) improve workability by enhancing the flow characteristics of the concrete mix and reducing water demand. Their pozzolanic and latent hydraulic properties lead to improved long-term strength and durability due to the formation of additional C-S-H gel during hydration processes. The section highlights how these materials not only enhance structural performance but also contribute to sustainability by optimizing resource utilization and reducing cement content. Additionally, the specific effects of each type of admixture are discussed in terms of desired outcomes in concrete applications.

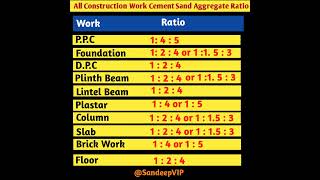

Youtube Videos

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Workability and Pumpability Improvement

Chapter 1 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Improves workability and pumpability.

Detailed Explanation

Mineral admixtures, especially those with spherical shapes like fly ash, can enhance the flow and handling of concrete mixtures. This means the concrete can be more easily mixed, poured, and worked with on construction sites. Improved workability also allows for smoother finishes and reduces the effort required for placement.

Examples & Analogies

Imagine trying to mix sand in water with a stick. If you throw in some marbles (representing mineral admixtures), the mixture flows and moves more freely, making it easier to work with.

Reduction in Water Demand

Chapter 2 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Reduces water demand.

Detailed Explanation

Adding mineral admixtures to concrete can lower the amount of water needed in the mix. This is because these materials can fill in the tiny gaps between the cement particles, reducing the overall volume of water required for a workable mixture. This reduction is crucial because less water leads to a denser and stronger concrete.

Examples & Analogies

Think of packing a suitcase. If you use clothes that can compress and fill in gaps, you can fit more in without needing a bigger suitcase (representing less water).

Long-Term Strength Enhancement

Chapter 3 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Enhances long-term strength.

Detailed Explanation

Mineral admixtures contribute to the development of strength over time in concrete. They participate in chemical reactions that continue long after the initial setting. For instance, substances like silica fume create additional binding compounds that reinforce the concrete’s structure as it ages, resulting in increased durability and longevity.

Examples & Analogies

Consider how fine wine gets better with age. Just like how certain ingredients enhance the wine's flavor over time, mineral admixtures work quietly, making concrete stronger as time passes.

Permeability Reduction

Chapter 4 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Reduces permeability.

Detailed Explanation

The use of mineral admixtures helps to seal off the tiny pores in concrete, which leads to reduced permeability. This means that water and other fluids cannot easily penetrate the concrete, which is essential for preventing damage from freeze-thaw cycles and chemical attacks.

Examples & Analogies

Think of a sponge. If you dip a sponge full of holes in water, it absorbs quickly. But if you had a tightly woven cloth, it wouldn’t soak up the water as easily. The cloth represents concrete enhanced with mineral admixtures.

Early Strength Characteristics

Chapter 5 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Slower early strength gain.

Detailed Explanation

While mineral admixtures generally enhance long-term strength, they can sometimes slow down the initial strength gain of the concrete. This is primarily because some of the chemical reactions that lead to hardening take longer to initiate, which can impact construction schedules if not properly managed.

Examples & Analogies

It's like cooking a slow-cooked stew; it may take longer to start bubbling (initial strength), but once it reaches that point, the flavors develop beautifully over time (long-term strength).

Heat of Hydration Reduction

Chapter 6 of 6

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Reduces heat of hydration.

Detailed Explanation

Mineral admixtures can lower the heat generated during the chemical reactions of concrete setting, known as heat of hydration. This reduction is particularly important in large and thick concrete placements, where excessive heat can lead to cracking and structural damage.

Examples & Analogies

Imagine making a batch of cookies. If you bake a thin layer it cooks quickly, but if you make a thick cake, it requires careful heat management to prevent burning the outside while the inside is still raw. Mineral admixtures help manage that heat effectively.

Key Concepts

-

Workability: The ease with which concrete can be mixed, placed, and finished.

-

Permeability: The ability of concrete to allow fluids to pass through, affecting durability.

-

Pozzolanic Activity: The reaction of certain materials with calcium hydroxide to form additional C-S-H.

Examples & Applications

Using fly ash can reduce the total amount of cement required in a concrete mix while maintaining strength.

In high-performance concrete, silica fume is often added to increase compressive strength and decrease the risk of corrosion.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

Concrete's best friend, mineral mix; Improves strength and helps it fix.

Stories

Once there was a concrete mix that desperately wanted to be strong. It found fly ash and silica fume, and together they helped it become an indomitable structure!

Memory Tools

WES is the key for mineral admixtures: Workability, Enhancement of strength, Sustainability.

Acronyms

P-S-D for remembering effects

Permeability reduction

Strength enhancement

Durability.

Flash Cards

Glossary

- Mineral Admixtures

Finely divided materials added to concrete to enhance its performance.

- Fly Ash

A by-product from burning pulverized coal used to improve concrete's strength and workability.

- Silica Fume

Ultra-fine by-product from silicon and ferrosilicon alloy production, enhancing concrete's strength.

- GGBS

Ground Granulated Blast Furnace Slag, a cementitious material enhancing durability and reducing heat of hydration.

- Permeability

The ability of concrete to allow water or liquid to pass through.

Reference links

Supplementary resources to enhance your learning experience.