Rice Husk Ash (RHA)

Enroll to start learning

You’ve not yet enrolled in this course. Please enroll for free to listen to audio lessons, classroom podcasts and take practice test.

Interactive Audio Lesson

Listen to a student-teacher conversation explaining the topic in a relatable way.

Origin and Production of RHA

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Today, we're talking about Rice Husk Ash, or RHA. It's produced by burning rice husks under controlled conditions to retain its high silica content. Can anyone tell me why controlling the burning conditions is important?

To keep the silica in it?

Exactly! Keeping a high amorphous silica content is crucial because it directly influences RHA's compatibility with concrete. What are some properties of RHA that you remember?

It has a fine particle size and can be gray or black.

Great! The fine particle size improves the workability of concrete, and its color can vary due to the burning conditions. Think of RHA as a hidden treasure in the waste from rice production!

So it’s sustainable too?

Absolutely! RHA not only utilizes agricultural waste but also improves concrete properties. That's a win-win for sustainability.

Effects of RHA on Concrete

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Now let's move on to the effects of RHA on concrete. One major benefit is that it reduces water absorption. Why do you think that matters?

It keeps the concrete stronger and less likely to degrade!

Exactly! Reduced water absorption leads to better durability. What else have you heard about RHA in concrete?

It increases strength when used in the right amount.

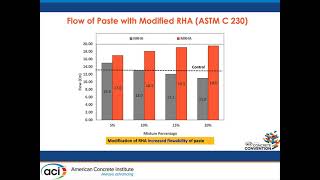

Correct! It can be a good replacement for silica fume, especially when we optimize its proportion during mixing. Can anyone recall the optimal replacement percentage for RHA?

Isn't it around 5-15%?

Spot on! Keeping it in that range ensures improved strength without compromising other concrete properties.

Advantages of Using RHA

🔒 Unlock Audio Lesson

Sign up and enroll to listen to this audio lesson

Let's summarize the advantages of incorporating RHA into our mixes. What are some of the benefits?

It enhances durability against aggressive environments!

Absolutely! RHA is particularly effective in environments that are corrosive. What else?

It uses waste material, so it helps the environment!

Yes! Utilizing agricultural by-products like rice husks not only promotes eco-friendliness but also significantly reduces costs. How do we specify the right amount of RHA to use?

By optimizing it based on the mix design!

Exactly! A properly optimized mix design is key to maximizing benefits while ensuring consistency in concrete performance. Remember, it’s all about balance!

Introduction & Overview

Read summaries of the section's main ideas at different levels of detail.

Quick Overview

Standard

RHA, produced by controlled burning of rice husks, contains high silica content and fine particles that contribute to reduced water absorption, increased strength, and enhanced durability in concrete. Its properties make it a viable substitute for silica fume.

Detailed

Rice Husk Ash (RHA)

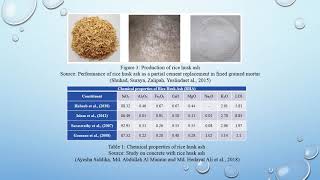

Rice Husk Ash (RHA) is derived from the burning of rice husks under controlled temperatures, ensuring the retention of a high amorphous silica content, which ranges between 85-95%. This ash exhibits fine particle size and varies in color from gray to black depending on the burning conditions. RHA plays a significant role in concrete applications due to its several advantageous effects:

- Reduced Water Absorption and Permeability: Incorporating RHA lowers the amount of water absorbed by concrete, thus improving its durability against various aggressive environments.

- Enhanced Durability: The material's binding nature helps enhance the overall durability of concrete structures.

- Increased Strength: When used in the optimal proportion, RHA can increase the strength of concrete mixes, making it a valuable replacement for more commonly used mineral admixtures like silica fume.

In summary, incorporating RHA into concrete has significant benefits that can improve structural integrity while promoting the sustainability of the construction industry.

Youtube Videos

![Rice husk as a by-product for concrete[technology] [construction]](https://img.youtube.com/vi/p4NcwPLhykc/mqdefault.jpg)

Audio Book

Dive deep into the subject with an immersive audiobook experience.

Origin and Production

Chapter 1 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

RHA is produced by burning rice husks under controlled temperature conditions to retain high amorphous silica content.

Detailed Explanation

Rice Husk Ash (RHA) is created through a specific process where rice husks, the waste products from rice milling, are burned. This incineration must occur under controlled temperature conditions. The term 'controlled' means that the temperature is managed carefully to ensure that the maximum silica content remains amorphous, which is important for its pozzolanic performance in concrete. The leftover ash is rich in silica, approximately between 85% to 95%, which is the key component that contributes to its usefulness in construction materials.

Examples & Analogies

Imagine making popcorn - if you heat the kernels too fast or too hot, they can burn and lose their fluffiness. Similarly, burning rice husks needs careful control to ensure that they maintain their beneficial properties, just like proper popcorn yields the best snack!

Properties

Chapter 2 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Properties

- High SiO₂ content (~85–95%)

- Fine particle size

- Color: Gray to black (depends on burning conditions)

Detailed Explanation

The properties of Rice Husk Ash (RHA) make it uniquely effective as a mineral admixture in concrete production. Firstly, its high silica content (about 85% to 95%) significantly enhances the pozzolanic reaction when mixed with cement. This means it reacts with calcium hydroxide in the presence of water to form bonds that improve the concrete's strength and durability. Secondly, the fine particle size of RHA contributes to better packing in the concrete mix, which can help in reducing porosity and enhancing structural integrity. Finally, the ash can vary in color from gray to black, which generally depends on how it was burned—consistent burning yields uniform colors.

Examples & Analogies

Think of RHA like the powdered sugar used in baking. The finer the powder, the better it mixes and integrates into the batter. Similarly, the fine particle size of RHA allows it to mix thoroughly with other concrete ingredients, leading to a smoother and stronger final product.

Effects on Concrete

Chapter 3 of 3

🔒 Unlock Audio Chapter

Sign up and enroll to access the full audio experience

Chapter Content

Effects on Concrete

- Reduces water absorption and permeability

- Enhances durability and resistance to aggressive environments

- Increases strength when used in optimum proportion

- Good replacement for silica fume in some cases

Detailed Explanation

Rice Husk Ash has a variety of beneficial effects on concrete when it is used as an admixture. The first and foremost is its ability to reduce water absorption and permeability. This property is crucial in preventing water and aggressive chemicals from seeping into the concrete, which can lead to degradation over time. Additionally, RHA contributes to the overall durability of the concrete. This means structures made with RHA can withstand harsher environmental conditions and have a longer lifespan. When proportioned correctly, using RHA can also enhance the strength of concrete, making it a viable alternative to more common admixtures like silica fume.

Examples & Analogies

Imagine a sponge - when it's tightly packed and dense, it holds less water and is less prone to damage by soaking. RHA makes concrete similarly robust, acting like a dense sponge that resists absorption and degradation!

Key Concepts

-

Rice Husk Ash: A sustainable by-product that enhances concrete properties.

-

Amorphous Silica: Crucial for the pozzolanic effects in RHA.

-

Reduction in Water Absorption: Improved durability in concrete applications.

Examples & Applications

Using RHA in a concrete mix improves resistance to environmental aggressiveness, particularly in coastal areas.

RHA can be used to substitute 10% of cement content in a typical concrete mix, resulting in better workability.

Memory Aids

Interactive tools to help you remember key concepts

Rhymes

RHA from rice husks, the ash we trust, in concrete we mix it, for strength that’s a must!

Stories

Once upon a time in a rice-producing village, husks were seen as waste. But a clever builder discovered that by burning them, he creates a magical ash that made his concrete stronger and more durable—saving the village money and protecting the environment.

Memory Tools

Remember RHA's properties with 'S-W-D': Strong (increases strength), Water-repellent (reduces absorption), Durable (improves durability).

Acronyms

RHA - Rice Husk Ash = Reduce, Harness, and Adapt!

Flash Cards

Glossary

- Rice Husk Ash (RHA)

A by-product of burning rice husks, rich in amorphous silica and used as a mineral admixture in concrete.

- Amorphous Silica

A non-crystalline form of silica that enhances binding properties in concrete.

- Permeability

The ability of concrete to allow water and other fluids to pass through.

- Workability

The ease with which concrete can be mixed, placed, and finished.

Reference links

Supplementary resources to enhance your learning experience.